B21, China Town Mall, Midrand

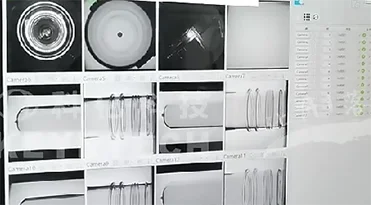

KEYETECH Cost-effective Full Automatic Inspection System Solution for PE PET Preforms

- Section : Medical Supplies

- Category : Testing Instrument

- SKU : 1601062418760

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 19 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What type of materials can the KEYETECH Inspection System inspect?

The KEYETECH Inspection System is designed to inspect PE and PET preforms, ensuring high-quality standards in production.

2. What is the power range of the KEYETECH Inspection System?

The system operates within a power range of 5000-7000W, providing optimal performance for quick and accurate inspections.

3. How accurate is the KEYETECH Inspection System?

The KEYETECH Inspection System boasts an outstanding accuracy rate of 99.5%, ensuring only the highest-quality preforms are passed for further processing.

4. What is the inspection speed of the system?

The system can inspect up to 300 preforms per minute, significantly boosting efficiency without compromising accuracy.

5. What are the dimensions of the KEYETECH Inspection System?

The system has a compact design with dimensions of 1995mm x 720mm x 1877mm (L*W*H), allowing it to fit into existing production spaces.

6. Is the system durable for continuous industrial use?

Yes, the KEYETECH Inspection System is made from durable 304 stainless steel, designed to withstand the demands of continuous operation in industrial settings.

7. What kind of packaging does the system come in?

The KEYETECH Inspection System is securely packaged in a non-fumigation wooden case, ensuring safe delivery and storage.

8. Can the KEYETECH Inspection System be customized?

Yes, the system supports both OEM and ODM customization, allowing for tailored solutions that fit specific operational needs.

9. What is the warranty period for the KEYETECH Inspection System?

The system comes with a 1-year warranty, providing assurance of continuous high-quality performance.

10. What types of defects can the system detect?

The KEYETECH Inspection System can detect defects such as black spots, color differences, impurities, cracks, gaps, bubbles, and more.

11. What components make up the inspection system?

The system features a high pixel industrial camera, high-resolution industrial lens, high brightness strobe light source, and a high-efficiency GPU processing platform.

12. What is the precision of the measurements taken by the system?

The system guarantees a precision of 0.1mm, ensuring detailed and accurate measurements to meet strict quality standards.

13. What is the weight of the KEYETECH Inspection System?

The system weighs 260kg, providing stability and durability during high-speed operations.

14. How does the system ensure effective lighting for inspections?

The system uses a self-developed LED light source imaging unit that provides full coverage of the UV to infrared spectrum for enhanced visual inspection.

15. Is the interaction interface user-friendly?

Yes, the KEYETECH Inspection System features a self-developed human-computer interaction system that is compatible with multiple protocols for easy connectivity.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading