B21, China Town Mall, Midrand

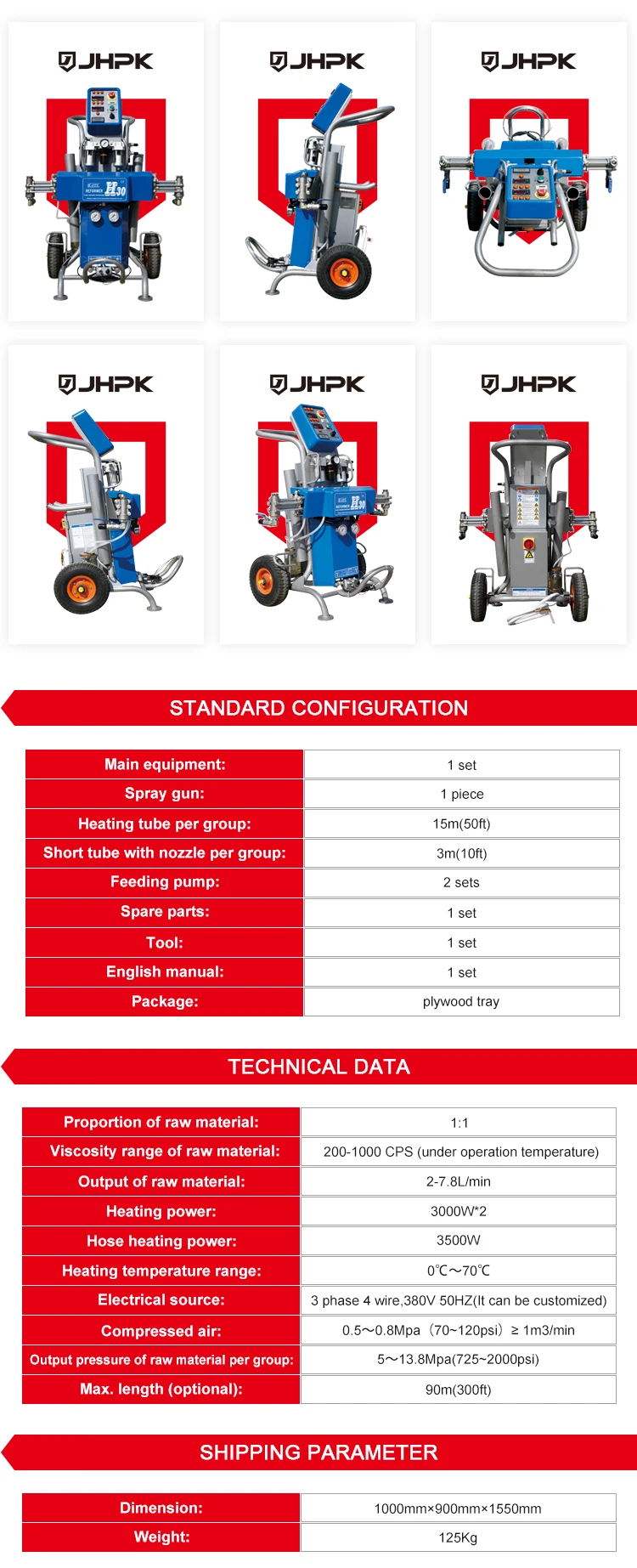

JHPK-H30 Polyurethane Spray Machine: Advanced Equipment for Polyurethane Project Applications

- Section : Machinery

- Category : Plastic & Rubber Processing Machinery

- SKU : 1600558038072-1712234050

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 19 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the JHPK-H30 Polyurethane Spray Machine?

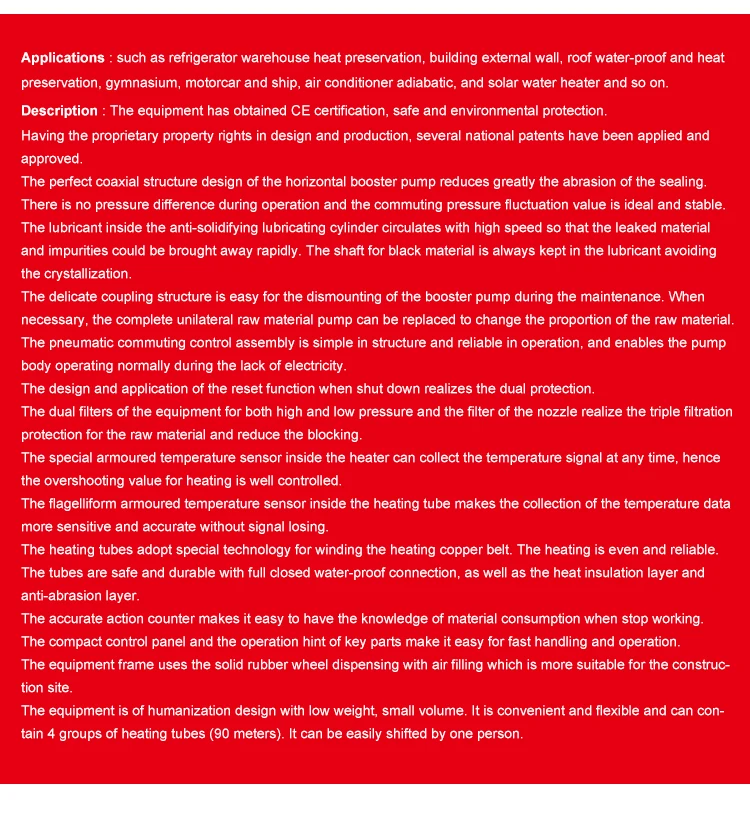

The JHPK-H30 is an advanced spray system engineered for applying polyurethane-based materials. It integrates proportioning, heating, and spraying functions to deliver consistent, high-quality polyurethane coatings, sealants, adhesives and foams for construction and industrial projects.

2. Which polyurethane formulations can the JHPK-H30 handle?

The machine is designed to work with a broad range of two-component polyurethane systems including coatings, elastomers, adhesives, sealants and certain sprayable rigid or semi-rigid foams, provided the material viscosities and pot-life are within the machine's operating range.

3. What are common applications for this machine?

Typical uses include roof and deck coatings, protective industrial coatings, insulation foam spraying, pipeline and tank linings, floor coatings, marine applications and general waterproofing and sealing projects.

4. How does the JHPK-H30 ensure accurate mixing of two-component materials?

It uses a precision proportioning system (mechanical or electronic) to meter base and curing agents at the correct ratio, plus a static or dynamic mixing head to ensure thorough blending immediately prior to atomization and spray.

5. Does the machine include material heating and temperature control?

Yes — the JHPK-H30 offers on-board heating and temperature control for material supply lines and the mixing head to maintain consistent viscosity and reaction characteristics during spraying.

6. What spray guns and nozzles are compatible with the JHPK-H30?

It is compatible with industry-standard two-component spray guns and a range of nozzle sizes and mixing elements. Specific gun and nozzle recommendations depend on the material and desired spray pattern, and many suppliers provide matching accessory kits.

7. What power and utility requirements does the JHPK-H30 have?

Power, air and utility requirements vary by configuration. Typical systems require a three-phase electrical connection for pumps and heaters and a compressed air supply for spray guns. Exact specifications are provided in the product datasheet or by the supplier for each model.

8. How portable is the JHPK-H30 for on-site jobs?

The unit is designed for field use and can be configured for portability with a compact chassis, tow or skid mounts and flexible hose lengths. Mobility options depend on the chosen configuration and accessories.

9. What routine maintenance does the machine require?

Routine care includes daily flushing/cleaning of material lines and mixing heads after use, inspection of seals and hoses, periodic pump and valve checks, filter replacements and verification of heaters and control electronics. Following the manufacturer's maintenance schedule maximizes reliability.

10. How do you clean the JHPK-H30 after use?

Clean promptly after each use by flushing with the recommended solvent or cleaner for the specific polyurethane system, following safe handling rules. Disassemble and inspect mixing elements and, if necessary, perform a deeper cleaning per the operator manual.

11. What safety features and precautions are recommended?

Use appropriate PPE (respirator, gloves, eye protection, protective clothing), ensure proper ventilation, follow grounding/anti-static procedures, keep emergency shutoffs accessible and adhere to material safety data sheets (MSDS). The machine may include safety interlocks and pressure relief devices; always follow the operator manual.

12. Is training available for operators of the JHPK-H30?

Yes. Manufacturers or authorized dealers typically offer operator and maintenance training, either on-site or at a training facility, covering setup, safe operation, troubleshooting and routine maintenance.

13. What support and spare parts are available?

Authorized dealers provide technical support, spare parts kits (seals, pumps, hoses, mixing elements) and repair services. It's recommended to keep common wear parts on hand to minimize downtime.

14. Can the JHPK-H30 be customized for specific project requirements?

Yes. Configurations and optional modules — such as different pump sizes, longer hose reels, alternate heating capacities, specialized spray guns or control packages — can typically be specified to match project scale and material properties.

15. How do I select the right model or configuration for my project?

Choose based on the polyurethane system (viscosity, pot life), required output rate, spray distance and pattern, site power/air availability and portability needs. Consult with the supplier or technical team, who can recommend the appropriate configuration and accessories.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading