B21, China Town Mall, Midrand

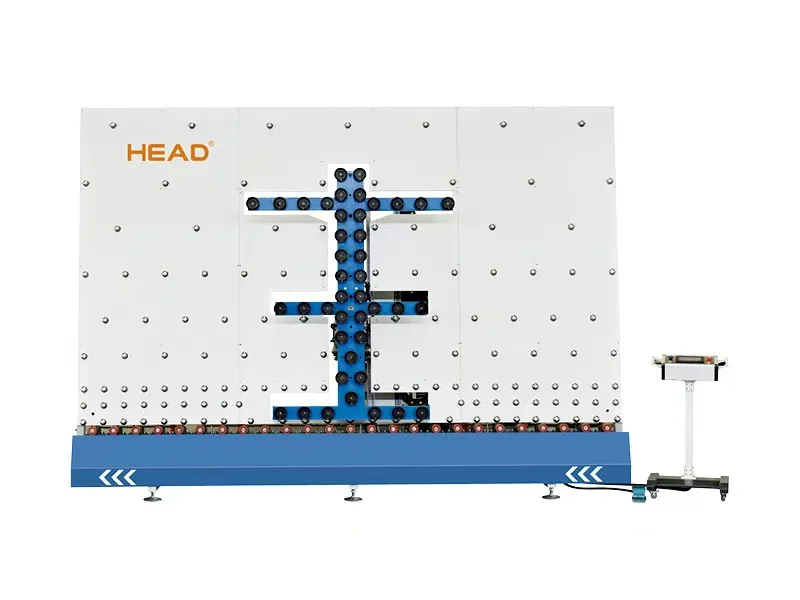

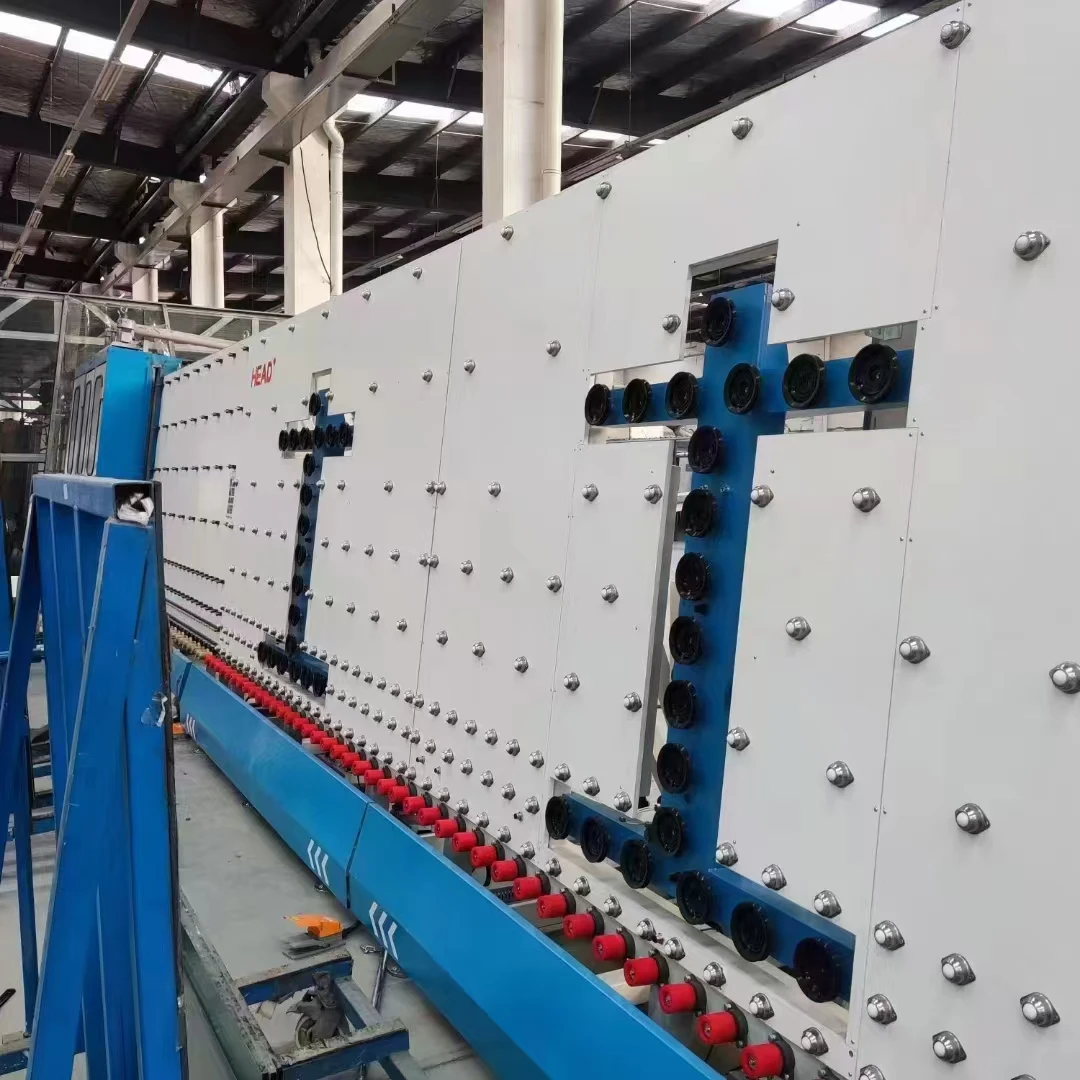

Insulating Glass Production Loading and Unloading Machine

- Section : Machinery

- Category : Manufacturing Machinery

- SKU : 1601349724795

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 03 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the primary function of the Insulating Glass Production Loading and Unloading Machine?

The primary function of the machine is to streamline the loading and unloading process of insulating glass, enhancing efficiency and safety for workers.

2. How does this machine improve production efficiency?

The machine replaces manual film loading with automated processes, reducing labor intensity and increasing loading speed, which significantly enhances overall production efficiency.

3. What safety features does the machine include?

The machine is designed to reduce risk factors associated with manual labor, making the loading and unloading process safer and more stable.

4. What technology is used in the Insulating Glass Production Loading and Unloading Machine?

It utilizes advanced technology, including servo motor and driver control, for precise film removal and stable placement.

5. What are the key components of this machine?

Key components include a XINJIE PLC (Programmable Controller), AirTAC pneumatic solenoid valve, Autonics photoelectric sensor, Panasonic proximity switch, and Schneider buttons and relays.

6. What types of businesses can benefit from this machine?

This machine is ideal for glass production factories, construction companies, and home renovation businesses.

7. Is this machine user-friendly?

Yes, the machine is designed with a user-friendly interface that allows operators to easily understand and control the loading and unloading processes.

8. What maintenance is required for the Insulating Glass Production Loading and Unloading Machine?

Regular maintenance includes checking and replacing worn components, ensuring sensors are functioning correctly, and keeping the machine clean for optimal performance.

9. Can this machine handle different sizes of insulating glass?

Yes, the machine is designed to accommodate various sizes of insulating glass, making it versatile for different production needs.

10. What is the expected lifespan of the Insulating Glass Production Loading and Unloading Machine?

With proper maintenance and care, the machine can have a long lifespan, significantly contributing to production efficiency over the years.

11. Does this machine require special installation?

While the machine is designed for easy setup, it is recommended to have trained technicians for installation to ensure optimal performance.

12. What is the capacity of the machine?

The capacity of the machine can vary based on specific configurations, but it is designed to handle high volumes efficiently.

13. Are there any training resources available for operators?

Yes, training resources and manuals are typically provided to help operators become familiar with the machine's functions and features.

14. What warranty options are available for this machine?

Warranty options may vary, but typically include coverage for parts and labor for a certain period; please check with the supplier for specific details.

15. How does the machine contribute to workplace safety?

By automating the loading and unloading process, the machine minimizes the need for manual handling, thereby reducing the potential for workplace injuries.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading