B21, China Town Mall, Midrand

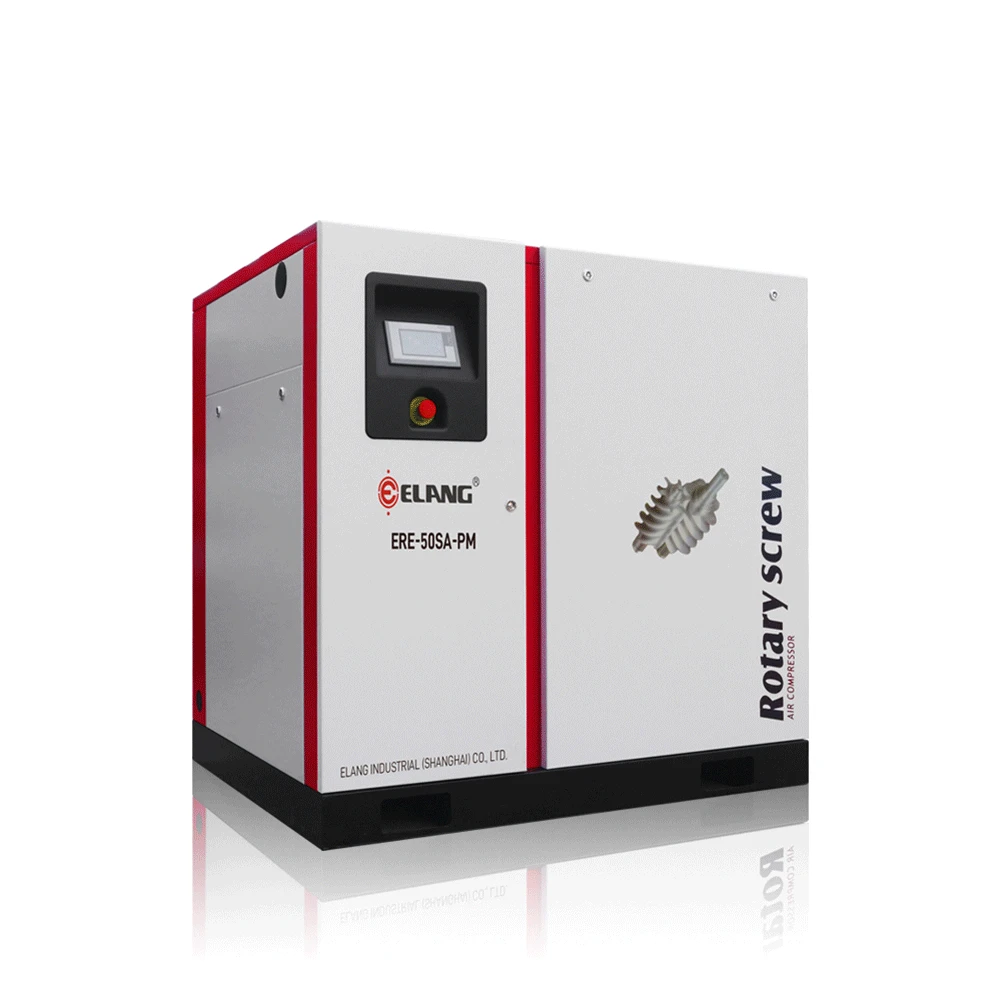

Industrial Screw Air Compressor Machine

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1600424353890

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 23 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the motor power of the ERE Series 10HP Industrial Screw Air Compressor?

The ERE Series 10HP Industrial Screw Air Compressor has a motor power of 7.5 kW, which is equivalent to 10 HP.

2. What is the air delivery range for the ERE Series compressors?

The air delivery for the ERE Series compressors ranges from 0.7 m³/min to 6.6 m³/min, depending on the specific model.

3. How does the intelligent PLC feature enhance the compressor's functionality?

The intelligent PLC features a touch screen with multiple languages, offers full protection functions for the motor and compressor, and allows for remote control via RS485 and IoT connectivity.

4. What is the maximum working pressure for the ERE Series compressors?

The maximum working pressure for the ERE Series compressors ranges from 7 to 13 bar, which is equivalent to 100 to 180 psi.

5. How does the energy-efficient cooler benefit the compressor's performance?

The energy-efficient cooler has a super large heat exchange area design, which improves cooling efficiency, prevents overheating, and prolongs the compressor's service life.

6. What materials are used in the construction of the ERE Series compressor?

The ERE Series compressor features high-quality construction with a solid structure, thicker canopy, and durable chassis for extended service life.

7. Is maintenance required for the ERE Series compressor, and how often?

Yes, the ERE Series compressor requires maintenance, but it is designed for low maintenance costs due to its reliable internal structure layout. Regular checks and scheduled maintenance are recommended for optimal performance.

8. Can the compressor operate in different working environments?

Yes, the high-quality fan assembly reduces noise and vibration, making the compressor versatile and suitable for various working environments.

9. What is the significance of the dust screen feature?

The dust screen protects the compressor system by stopping dust, moisture, and other particles, which helps to extend the life of components like the air end, air filter, and oil filter.

10. How does the air end design contribute to the compressor's efficiency?

The air end utilizes a new-generation profile with an integrated shaft structure, which ensures stable operation and high energy efficiency.

11. What is the weight of the ERE-10SA model?

The ERE-10SA model weighs 110 kg.

12. What are the dimensions of the ERE-20SA model?

The ERE-20SA model has dimensions of 1010 x 600 x 1030 mm.

13. How does the inverter and PM motor enhance energy efficiency?

The inverter and PM motor enable the compressor to adjust frequency for energy efficiency, resulting in lower energy consumption and improved stability.

14. Are there different models available in the ERE Series?

Yes, the ERE Series offers multiple models, including the ERE-10SA, ERE-20SA, ERE-30SA, and ERE-50SA, each with varying motor power and air delivery capabilities.

15. What is the oil-gas tank capacity and its benefits?

The oil-gas tank is designed with a super large capacity, which ensures lower system pressure differences and enhances the efficiency of oil-gas separation.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading