B21, China Town Mall, Midrand

Hydraulic Press Machine Q35Y-16

- Section : Machinery

- Category : Machine Tool Equipment

- SKU : 62335725733

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 06 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What are the main specifications of the Hydraulic Press Machine Q35Y-16?

Key specs: return force 600 kN; slide stroke 80 mm; motor power 4 kW; weight ~1.6 tons; dimensions 1650 mm (L) × 800 mm (W) × 1780 mm (H); standard voltage 380 V. CE and ISO certified.

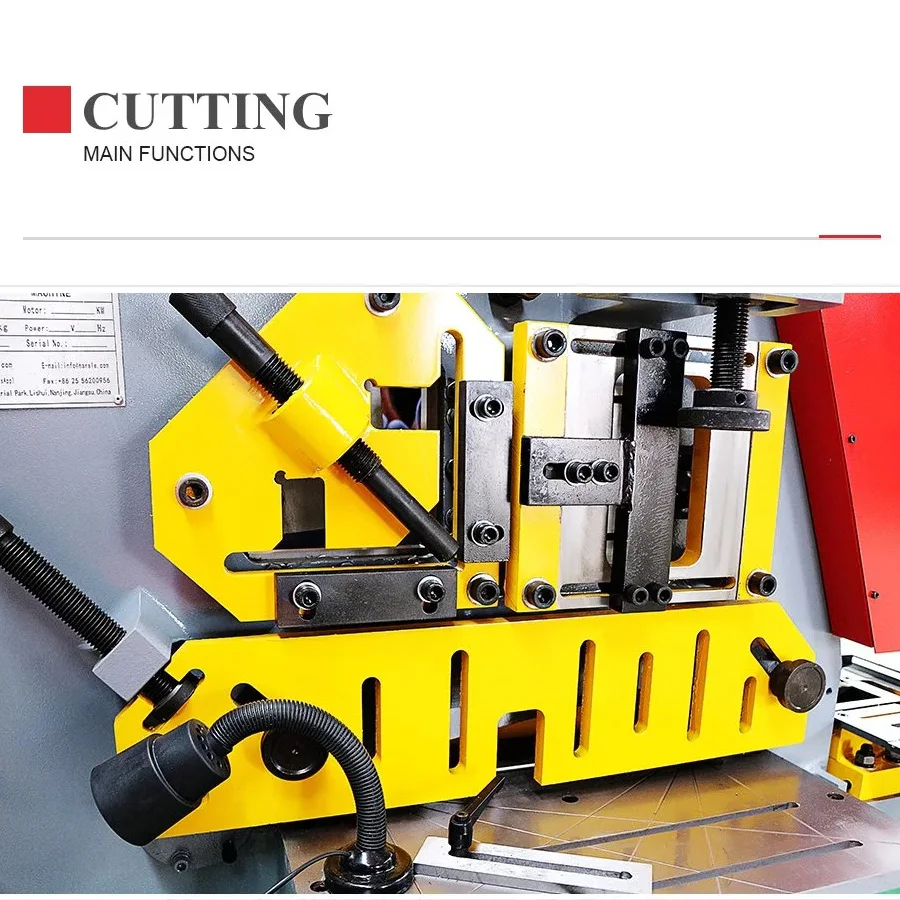

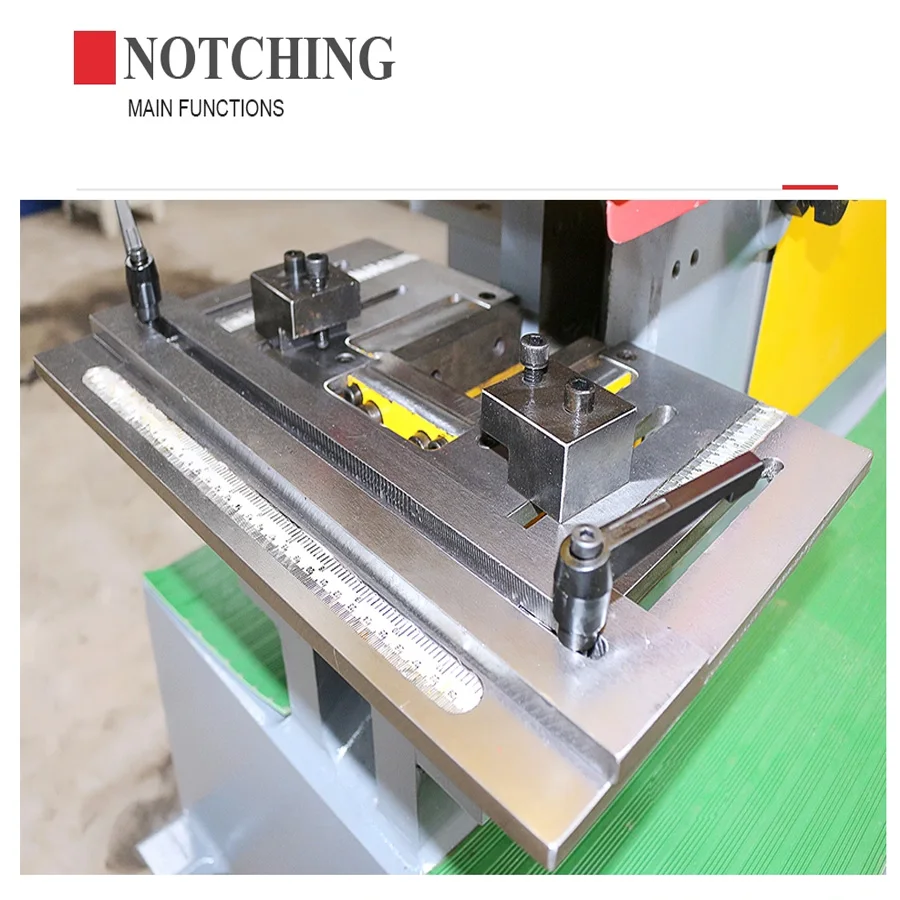

2. What applications is the Q35Y-16 designed for?

Designed for metal processing and stamping tasks including punching, shearing, cutting, notching and bending of plates, flat bars, round/square bars, angle, channel and I-beam sections.

3. What tooling and operations are supported?

Supports a full range of punches, dies and shear blades. Operations include hole punching (universal punches/dies), angle and channel cutting, round/square bar shearing, plate shearing, notching, and 45° angle cuts for picture-frame corners.

4. How easy is it to change tooling?

The machine uses a quick-change coupling nut and sleeve system for rapid replacement of punches/dies. The design includes accessible stripper and gauging table features to simplify tooling changes.

5. What safety features does the Q35Y-16 include?

Safety features include large strong guarding around cutting areas, viewing windows and stripper swing-away for safe access, adjustable hold-down devices, and standard safety stops. Operators should still follow local machine-safety regulations and wear PPE.

6. What are the power and installation requirements?

Electrical: standard 380 V three-phase supply (confirm local compatibility). Mechanical: machine weight ~1.6 tons—use appropriate lifting equipment for placement and provide a stable, level foundation. Exact electrical wiring and foundation specs are provided in the installation manual.

7. What maintenance is required and how often?

Designed for low maintenance, but regular tasks include checking hydraulic oil level and condition, inspecting hoses and fittings for leaks, lubricating moving parts per manual schedule, checking tooling for wear, and tightening fasteners. Follow the Lifeng maintenance checklist in the manual for intervals.

8. What hydraulic fluid should be used?

Refer to the operator manual for the recommended hydraulic oil viscosity and specification for your operating temperature range. Use only manufacturer-recommended or equivalent fluids and change them at the intervals specified in the manual.

9. Can the machine handle heavy or thick materials?

The Q35Y-16 is built for heavy-duty stamping with a 600 kN return force, but cutting/shearing and punching capacity depend on material type, thickness, and selected tooling. Consult the machine's capacity charts or contact Lifeng with your material specs for confirmation.

10. Are custom voltages or configurations available?

Yes — the machine can be supplied with customized electrical configurations and tooling packages to suit local power standards and application needs. Contact your Lifeng dealer to discuss available customization options.

11. What accessories and spare parts are available?

Available accessories commonly include sets of punches and dies, shear blades (including diamond-shaped blades), hold-down devices, gauging stops, and guarding. Spare parts and consumables are available through Lifeng or authorized distributors.

12. Is operator training required?

Operators should receive training on safe operation, tooling changes, routine maintenance, and emergency procedures. Lifeng or authorized dealers typically offer start-up support and training — check with your supplier.

13. What certification and quality standards does the Q35Y-16 meet?

The Q35Y-16 is manufactured to ISO quality system standards and carries EU CE certification, indicating conformity with applicable safety and performance requirements.

14. How compact is the machine and will it fit my workshop?

Footprint dimensions are 1650 mm long × 800 mm wide × 1780 mm high. Weight is approximately 1.6 tons — ensure you have adequate floor space, crane/forklift access for installation, and clearance for safe operation and maintenance.

15. What warranty and after-sales support are available?

Warranty terms and after-sales service packages vary by region and supplier. Contact your Lifeng distributor or dealer for specific warranty details, service contracts, spare parts supply and local technical support options.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading