B21, China Town Mall, Midrand

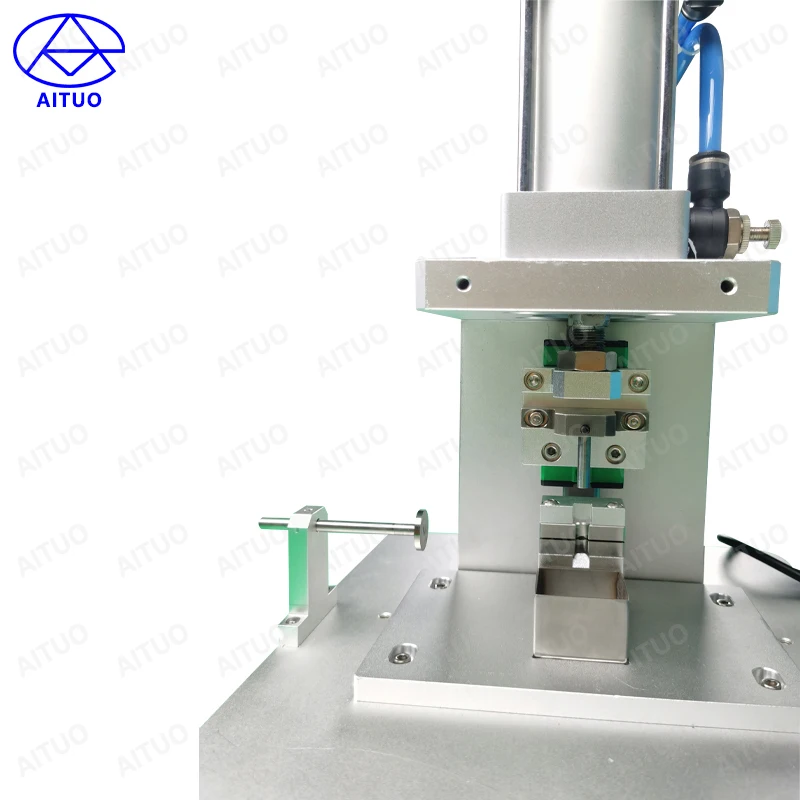

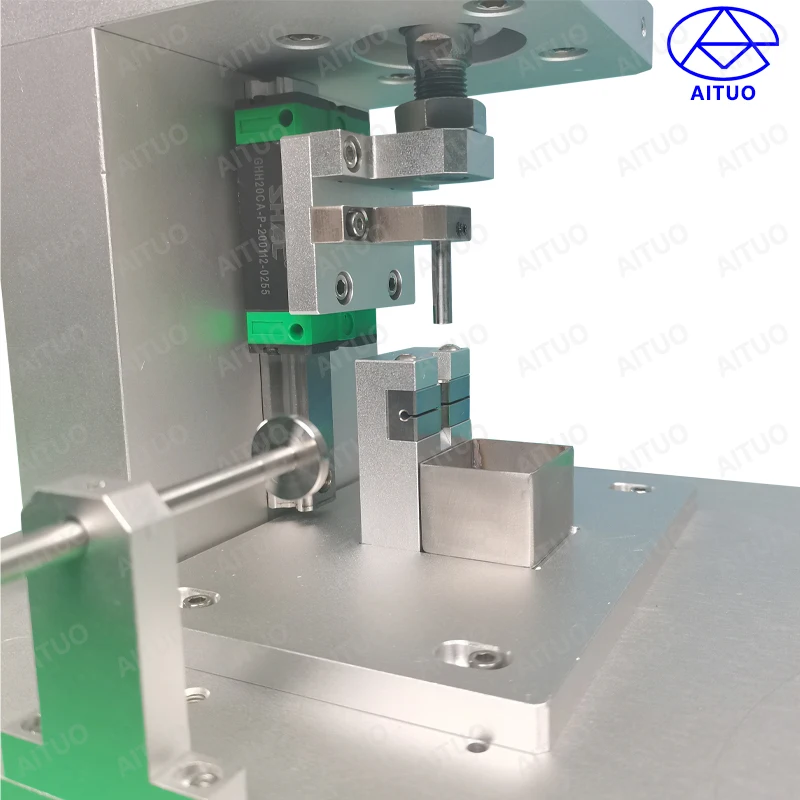

Holes Drilling Machine for Catheters - AM

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1600468592486

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 24 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Holes Drilling Machine for Catheters - AM used for?

It is a specialized punching/drilling machine designed to create precise holes in medical tubing and catheters (e.g., central venous, dialysis, PICC, urinary catheters, drainage catheters and other similar products).

2. Which materials can this machine process?

Applicable materials include PVC, PU, TPU, HDPE, LDPE, PP, PEBAX and similar medical-grade polymers.

3. What tube diameters (French sizes) can it handle?

The machine processes tubes in the range of 4FR to 10FR. (FR = French gauge; 1 FR = 0.33 mm outer diameter.)

4. What are the main technical specifications (spindle speed, motor, power)?

Variable spindle speed: 1–6000 RPM. Motor: 2.1 kW. Power supply: AC 220 V, 10 A, 50 Hz. The documentation also lists a drilling speed value of 300–600 (see next FAQ for clarification).

5. What does the listed 'drilling speed 300–600' mean?

The description states a drilling speed of 300–600 but does not specify units (e.g., holes/min, feed rate, or rpm). Use the variable spindle speed (1–6000 RPM) for setting cutting speed and confirm the intended 'drilling speed' units with AM or in the technical manual.

6. What are the machine dimensions and weight?

Two sets of dimensions/weights appear in the product text: a compact spec (36 cm × 28 cm × 48 cm, 13 kg) and a product-info spec (460 mm × 600 mm × 495 mm, 42 kg). Please confirm the correct model/configuration with AM before ordering, as packaging or different configurations may account for the discrepancy.

7. What are the fixture and tool sizes?

Fixture size: 40 mm × 10 mm × 15 mm (L×W×H). Tool size: 25 mm × 10 mm × 3.8 mm (L×W×thickness). For other tooling geometries, contact AM for custom tools or replacements.

8. What are the environmental and pneumatic requirements?

Ambient operating temperature: −20°C to +50°C. Working (air) pressure: 0.5–0.8 MPa. Ensure stable power (AC 220 V) and required compressed air quality as per your facility standards.

9. What safety features and operator requirements exist?

The listing does not detail safety features. Operators should receive training, use appropriate PPE (eye/hand protection, hearing protection if required), follow lockout/tagout when servicing, and work within cleanroom/production area protocols for medical device manufacturing. Confirm built-in guards and emergency stop functions with the supplier.

10. Is tooling consumable and are spare parts available?

Yes — cutting tools are consumable and normally replaceable. Contact AM or your distributor for spare blades, fixtures, and recommended spare-parts kits. Ask about lead times for critical consumables.

11. What maintenance is required and is technical support provided?

Regular maintenance typically includes tool inspection/replacement, spindle lubrication/checks, pneumatic system checks, and cleaning to prevent contamination. The machine includes a 1-year warranty; contact AM for recommended maintenance intervals and technical support options or service contracts.

12. Does the machine support custom hole sizes, patterns, or multi-hole configurations?

The machine is designed for precise drilling and commonly supports different tooling and fixtures for varied hole patterns. For custom hole diameters, spacing, or automated patterns, discuss your requirements with AM so they can advise on suitable tooling or customization.

13. What is the typical production throughput?

Throughput depends on tube size, hole count per part, hole geometry, operator skill, and cycle settings. The published specs do not give a definitive parts-per-minute rate; request sample testing or production estimates from AM with your specific application for accurate throughput figures.

14. Is the machine certified for medical device manufacturing (CE, FDA, ISO)?

No certifications are listed in the provided description. If you require CE, FDA, ISO 13485 or other regulatory documentation, request certification and validation documents directly from AM before purchase.

15. How should the machine be cleaned to maintain sterility/contamination control?

The machine should be cleaned according to your facility's medical-device manufacturing SOPs. Use validated cleaning agents compatible with the materials of the fixtures and tooling, avoid residue on parts handling surfaces, and perform cleaning in controlled areas. AM can advise on recommended cleaning procedures and materials compatibility.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading