B21, China Town Mall, Midrand

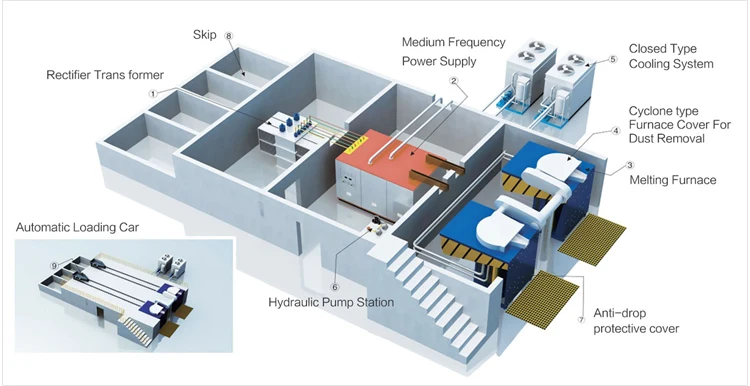

High Temperature 1500kg Industrial Electric Scrap Cast Iron Foundry Smelting Reheating Crucible Copper Melt Induction Furnace

- Section : Machinery

- Category : Industrial Machinery

- SKU : 62367189962

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 03 Feb, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the maximum capacity of the induction furnace?

The High Temperature Industrial Electric Induction Furnace has a maximum capacity of 1500kg.

2. What materials can be melted using this furnace?

This furnace is designed for melting scrap cast iron and copper, making it suitable for foundry applications.

3. How does the multifunctional protection system work?

The built-in multifunctional protection system monitors various parameters like over-voltage, over-current, and load pressure to ensure safe and reliable operation of the furnace.

4. What safety features does this induction furnace have?

The furnace includes good insulation treatment to prevent electric leakage and ensure worker safety during operation.

5. Is maintenance difficult for this induction furnace?

The furnace is designed for easy maintenance with fewer relay components and intuitive adjustments, making it easier to debug and maintain.

6. What type of water pipes are recommended for use with this furnace?

It is recommended to use high-quality water pipes to minimize aging and leakage, ensuring safe operation.

7. How can I ensure the longevity of the furnace?

Using high-quality materials, including copper tubes and water pipes, along with regular maintenance, will help extend the lifespan of the furnace.

8. What type of power supply does this induction furnace require?

The furnace requires a compatible industrial power supply that meets its operational voltage and current specifications.

9. Can this furnace be used for continuous operation?

Yes, the furnace is designed for industrial use and can operate continuously, provided it is maintained properly.

10. What happens if there is a power leakage?

If power leakage is detected, the furnace should be immediately stopped for maintenance to prevent economic losses and ensure safety.

11. How does this induction furnace compare to traditional melting methods?

This induction furnace is more energy-efficient, offers precise control over melting temperatures, and provides a safer working environment compared to traditional methods.

12. What are the dimensions of the furnace?

The specific dimensions can vary, so it is best to consult the manufacturer's specifications for accurate measurements.

13. Is training available for operating the induction furnace?

Many manufacturers offer training programs for operators to ensure safe and efficient use of the induction furnace.

14. What kind of warranty does this furnace come with?

Warranty details can vary by manufacturer, so it is advisable to check the warranty policy at the time of purchase.

15. Can I use this furnace for both scrap metal and foundry work?

Yes, it is versatile enough to be used for both scrap metal melting and foundry applications.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals