B21, China Town Mall, Midrand

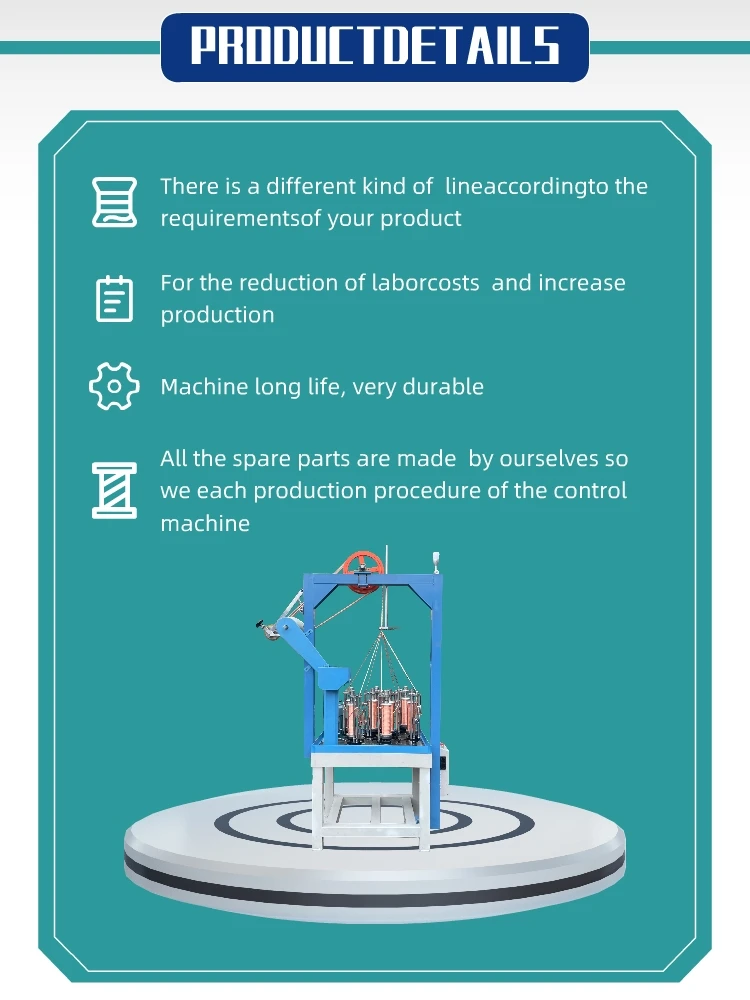

High Speed Copper Wire Hose Braiding Machine Rotary Braiding Machine

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1601201056609

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 13 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the maximum speed of the High Speed Copper Wire Hose Braiding Machine?

The machine operates at high speed, although the specific maximum speed can vary based on the model. It is designed to maintain high efficiency while remaining noiseless.

2. Is the machine suitable for small workshops?

Yes, the compact design of the machine makes it ideal for small workshops as it saves space without compromising on performance.

3. Can I use different types of yarn with this machine?

Yes, the machine can accommodate yarn packages that are generally available in cone form, allowing for versatility in the types of yarn used.

4. What safety features does the machine have?

The machine is equipped with an auto stop system that reacts sensitively to yarn breakage or depletion, ensuring safety and reducing yarn waste.

5. How can I adjust the density of the produced cord?

The density of the produced cord can be adjusted by changing the pitch gears system, allowing you to customize the output according to your requirements.

6. Is it easy to operate the machine?

Yes, the machine is designed for ease of use, featuring a frequency control motor that allows for simple speed adjustments.

7. What is the maintenance requirement for the machine?

Regular maintenance involves checking the yarn feed system, ensuring the pitch gears are set correctly, and keeping the machine clean to ensure optimal performance.

8. How does the auto stop system work?

The auto stop system detects when the yarn is either broken or runs out, automatically stopping the machine to prevent further waste and ensure safety.

9. Can I produce different sizes of products with this machine?

Yes, by changing the pitch gears, you can produce different sizes of products, making the machine versatile for various applications.

10. What are the dimensions of the machine?

The specific dimensions can vary by model, but it is designed to be compact for space-saving purposes. Please refer to the product specifications for exact measurements.

11. Is it noisy during operation?

No, the High Speed Copper Wire Hose Braiding Machine is designed to operate noiselessly, making it suitable for environments where noise is a concern.

12. What is the power source required for the machine?

The machine typically requires a standard electrical power supply. Please check the product specifications for the exact voltage and power requirements.

13. How does this machine lower labor costs?

By automating the braiding process and reducing the likelihood of yarn waste due to its auto stop feature, the machine can significantly lower labor costs and increase production efficiency.

14. What types of cords can be produced with this machine?

The machine can produce various types of cords, including those used in manufacturing hoses, cables, and other applications that require braided cord.

15. Is training available for operating the machine?

Many suppliers offer training and support for operating the machine, ensuring that users can quickly learn how to maximize its capabilities.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading