B21, China Town Mall, Midrand

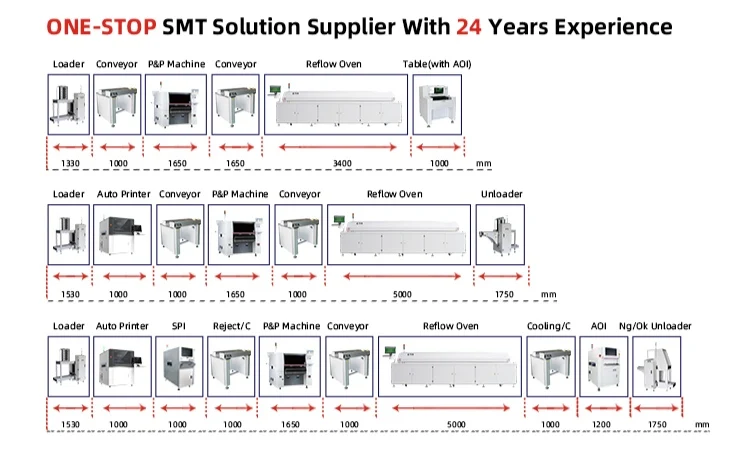

High Precision High Resolution SMT off-line with Electronics Production Machinery Complete Line SMT machines

- Section : Machinery

- Category : Manufacturing Machinery

- SKU : 1600489533094

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 23 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What does SMT stand for?

SMT stands for Surface Mount Technology, which is a method for producing electronic circuits where the components are mounted directly onto the surface of printed circuit boards (PCBs).

2. What is the purpose of the High Precision High Resolution SMT machine?

The High Precision High Resolution SMT machine is designed for assembling electronic components onto PCBs with high accuracy and resolution, making it ideal for laptop and smartphone manufacturing.

3. What types of products can this SMT line assemble?

This SMT line can assemble a variety of electronic products, including laptops, smartphones, and other devices that require high-quality PCB assembly.

4. Is the SMT machine suitable for small-scale production?

Yes, the SMT machine is suitable for both small-scale and large-scale production, offering flexibility to accommodate various manufacturing needs.

5. What is the maximum resolution this SMT machine can achieve?

The machine is capable of achieving high precision placements, typically within a range of 01005 components, depending on the specific model and configuration.

6. Does the SMT line come with software for operation?

Yes, the SMT line is typically equipped with user-friendly software that allows for easy programming and monitoring of the assembly process.

7. What are the main components included in the complete SMT line?

The complete SMT line generally includes a pick and place machine, solder paste printer, reflow oven, and inspection equipment to ensure quality control.

8. What is the lead time for delivery after ordering the SMT machine?

The lead time for delivery can vary depending on the manufacturer and model, but it is typically between 4 to 8 weeks after order confirmation.

9. Are training and support available after purchase?

Yes, most manufacturers offer training and ongoing technical support to ensure customers can effectively operate and maintain the SMT machinery.

10. What is the power consumption of the SMT machines?

Power consumption varies by model, but average SMT machines consume between 2 to 5 kW during operation. Detailed specifications can be provided upon request.

11. Can the SMT machine handle different sizes of PCBs?

Yes, the SMT machine can be configured to handle a range of PCB sizes, ensuring flexibility for various projects.

12. What type of maintenance is required for the SMT line?

Regular maintenance includes cleaning the machine, checking alignment, and performing software updates to ensure optimal performance and longevity.

13. Is the SMT line compliant with industry standards?

Yes, the SMT line is designed to comply with relevant industry standards, including IPC standards for electronic assembly.

14. What materials are compatible with the SMT machine?

The SMT machine is compatible with a wide range of materials, including various types of PCBs, SMD components, solder paste, and adhesives.

15. Can the SMT machine be integrated with existing production lines?

Yes, the SMT machine can often be integrated with existing production lines, allowing for a seamless workflow and enhanced productivity.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading