B21, China Town Mall, Midrand

Hand Press Cutter Tool Feeding 15cm for Leather Work DIY Stamping Cutter Pattern sldb

- Section : Electrical & Tools

- Category : Tools & Hardware

- SKU : 1601004831496

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 29 Jan, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Hand Press Cutter Tool (Feeding 15cm)?

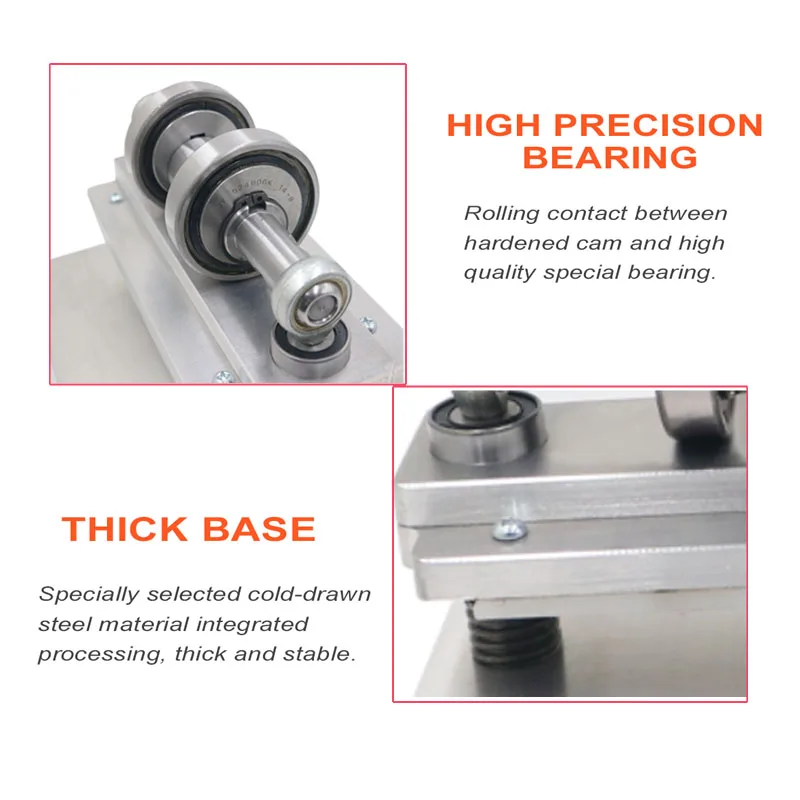

A manual cutter press designed for stamping and cutting with cutter dies, mainly for leather work and DIY patterns. It is portable, space-saving, and has a net weight of 5.2 kg. The product supports a feed width of 15 cm.

2. What does "Feeding 15cm" mean?

Feeding 15 cm refers to the maximum width of material the press is designed to accept or the typical maximum working width for your dies and patterns. If you need to process wider pieces, you will need to reposition the material or use a larger press.

3. Which materials can this press cut or stamp?

It is suitable for leather, paper, PVC film and many other thin-to-medium materials. Actual performance depends on material type, thickness, and the cutting die used.

4. What material thickness can it handle?

Maximum thickness depends on the die geometry, material, and how you set the press. The product is intended for thin to medium materials commonly used in small leatherwork projects. Test on scrap pieces to determine suitable thickness for your specific die and material, or consult the seller for recommendations.

5. Are cutting dies included with the press?

The product description does not specify included dies. Many sellers supply the press only and offer dies separately or as a customization option. Check the product listing or contact the seller to confirm what is included.

6. Can I customize or order a custom mould/die?

Yes. The description states moulds can be customized. Provide the seller with your artwork, dimensions and material requirements to get a custom die made.

7. How do I set up the press for the first time?

Basic setup typically includes: securely mounting or clamping the press to a sturdy work surface, fitting and aligning the die on the press bed, placing a suitable backing board or cutting mat under the material, making a trial cut with scrap material, and making small adjustments to alignment and pressure as needed. Refer to any supplied manual or contact the seller for product-specific instructions.

8. How do I operate the press safely?

Keep hands and fingers clear of the die area while operating, wear cut-resistant gloves if appropriate, ensure the press is securely mounted, use proper eye protection for debris, and keep children or bystanders away during use. Make deliberate, controlled presses rather than forcing the lever.

9. How do I maintain and care for the press?

Wipe away dust and scraps after use, periodically lubricate pivot points with a light machine oil, check and tighten any fasteners, store in a dry place to prevent rust, and inspect dies for burrs or damage before use.

10. Is this press suitable for small production runs or only one-off projects?

The press is marketed as a smart, portable and space-saving option suitable for small projects and short production runs. For high-volume industrial production you may want a heavier-duty or powered press.

11. Can the press be bolted or clamped to a workbench?

Most hand press units of this type are designed to be clamped or bolted down for stability. The product listing does not provide specific mounting hole details—check the seller's spec sheet or contact them to confirm mounting options and hole spacing.

12. What dies or mounting sizes are compatible with this unit?

Compatibility depends on the die footprint and how it mounts to the press bed. Because specifications are not detailed in the listing, confirm maximum die plate dimensions and recommended mounting method with the seller, or provide your die size when asking about compatibility.

13. Do you need a backing board or cutting mat when using this press?

Yes—using a durable backing board or cutting mat beneath the material improves cut quality, protects both the die and press bed, and extends die life. Replace the backing when it becomes worn or compressed.

14. What should I do if my cut isn't clean or complete?

First check die sharpness and alignment. Ensure the material is flat and properly supported on a backing board, increase pressure in small increments if possible, and try multiple light passes rather than a single forced press. Re-sharpen or replace worn dies as needed.

15. Is there warranty, spare parts or after-sales support?

The product description does not specify warranty or spare parts. Contact the seller or retailer for details about warranty coverage, availability of replacement parts, die services and after-sales support.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals