B21, China Town Mall, Midrand

GW42 Auto Steel Bar Bender Rebar Bending Machine

- Section : Machinery

- Category : Machine Tool Equipment

- SKU : 1600924888978

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 27 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

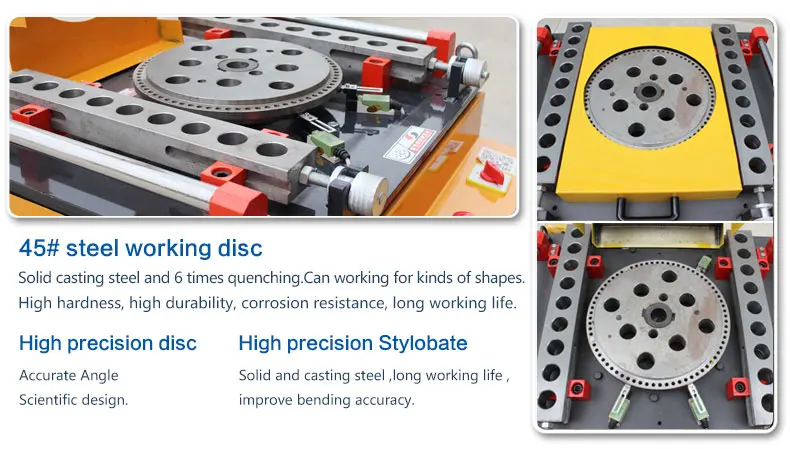

1. What is the GW42 Auto Steel Bar Bender Rebar Bending Machine?

The GW42 is an automatic rebar bending machine designed for bending round and deformed (class) steel bars. It features an automatic/digital control panel, worm-gear drive and is built for construction and precast applications that require fast, repeatable bends.

2. Which models are available in this GW series?

The series includes GW40E, GW40F, GW42D, GW42, GW50C and GW50E. Each model differs in bending range, disk diameter, overall size and weight to suit different site needs.

3. What is the bending range of the GW42 model?

GW42 bends round bars from 6 mm up to 42 mm and class (deformed) bars from 6 mm up to 32 mm.

4. What motor power and speed does the machine use?

Motor power options are 3 kW or 4 kW (model-dependent). Motor speed is 1,440 rpm.

5. What input voltage does the machine require?

The machine accepts three-phase supply—standard options are 220 V, 380 V or 415 V. Custom voltage configurations are available on request.

6. What is the disk diameter on the GW42?

The GW42 model uses a 350 mm bending disk. (GW50-series models use a 400 mm disk.)

7. What are the overall dimensions and weight of the GW42?

The GW42 overall size is 850 × 900 × 900 mm and its net weight is approximately 310 kg.

8. What driving and operation modes does the machine use?

The GW42 uses a worm-gear driving mechanism and operates via an automatic digital control panel for preset and repeatable bends.

9. Can I preset bending angles and how accurate are they?

Yes — the digital control panel allows you to preset bending angles and counts for repeatable production. Actual accuracy depends on material, bar size and setup; fine adjustments are made through the control panel.

10. What types of steel bars can this machine bend?

It is designed for typical construction rebar: round bars and deformed (class) bars within the specified model ranges (for GW42: round 6–42 mm, class 6–32 mm).

11. What are the basic installation and power requirements?

Install on a level, stable surface with sufficient clearance. Connect to the specified three-phase supply by a qualified electrician, ensure correct phase wiring and proper earthing. Consult the supplier for foundation or anchoring recommendations.

12. What routine maintenance is required?

Regular maintenance includes daily cleaning of debris, periodic lubrication of gears/worm gear and pivot points, routine inspection and tightening of fasteners, and inspection of the motor and electrical connections. Follow the supplier's maintenance schedule for intervals and lubricants.

13. What safety precautions should operators follow?

Operators should wear PPE (gloves, eye protection, safety boots), keep hands and loose clothing away from moving parts, ensure emergency stop and guards are functional, and only allow trained personnel to operate the machine. Follow local machine-safety regulations.

14. Are spare parts and accessories available?

Common spare parts (bending disks, rollers, electrical components, gears) and accessories are typically available. Contact the supplier with your model number for part numbers, lead times and pricing.

15. Is customization, warranty or certification offered?

Voltage and certain configuration customizations are available. Warranty terms, CE/ISO or other certifications and shipping options vary by supplier—contact the manufacturer or dealer for detailed warranty coverage, certifications and customization options.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading