B21, China Town Mall, Midrand

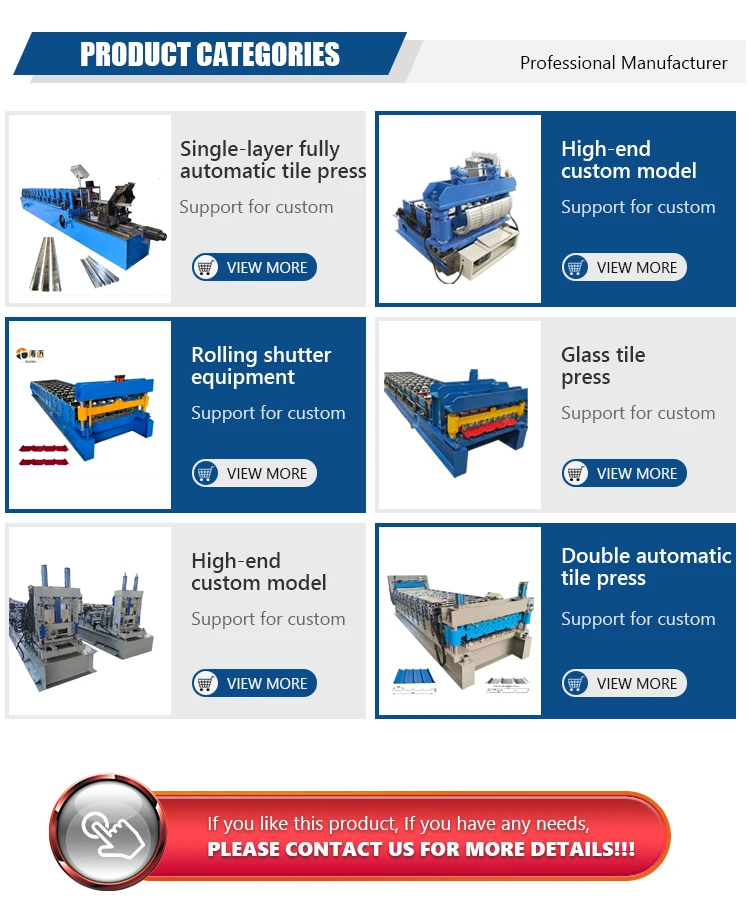

Forming Making Machine Brace Tile Making Machinery

- Section : Machinery

- Category : Tile Making Machinery

- SKU : 1601050357772

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What does the Forming Making Machine (Brace Tile Making Machinery) produce?

It roll-forms color-coated steel coils into various roof and wall tile profiles (corrugated/brace tiles and other wave types) used for industrial, commercial and civil buildings.

2. What are the typical applications for the panels produced by this machine?

Finished panels are used for roofing and wall cladding of warehouses, factories, large-span steel structures, residential buildings and interior/exterior decorative walls.

3. What raw materials can the machine process?

It is designed for color-coated steel coils (pre-painted galvanized or galvalume). Other coated or coated-to-spec cold-rolled steel coils are usually supported; confirm exact material compatibility with the supplier.

4. What are the main known technical features of the machine?

Key features: heavy main frame built from 350H steel, PLC control system (imported brand), new condition, CE and ISO certification. Specifics such as station count, roller diameter and hydraulic specs depend on model/configuration.

5. Is the control system automatic and what brand is used?

Yes — the machine uses an imported-brand PLC for automated forming and parameter control. A human–machine interface (HMI) is typically provided for easy operation and adjustments.

6. What production speed and capacity can I expect?

Production speed varies by profile, material thickness and machine configuration. Typical roll-forming speeds are in the range of about 8–18 m/min. Exact capacity should be confirmed for your chosen profile and setup.

7. What material thickness and finished widths does the machine handle?

Thickness and width are model-dependent. Common thickness ranges are approximately 0.3–0.8 mm for color-coated steel, and finished panel widths are customizable. Provide your required thickness and finished width to get exact specs.

8. Can the machine produce custom profiles and colors?

Yes. Profile geometry and panel color follow client requirements: the forming tools (rolls/dies) can be customized and panels are produced from the color-coated coils specified by the customer.

9. What are the electrical and power requirements?

Power requirements depend on the machine configuration and local standards. A typical configuration uses three-phase power (e.g., 380V 50Hz). The supplier will provide exact electrical specifications for the selected model.

10. What installation, training and commissioning services are provided?

Suppliers commonly offer on-site installation and commissioning, plus operator training. Confirm whether these services are included or available as paid add-ons prior to purchase.

11. What warranty and after-sales support are available?

Warranty terms vary by manufacturer. Most suppliers provide a standard warranty period and lifetime technical support, plus availability of spare parts. Ask the vendor for specific warranty duration and after-sales policies.

12. How is routine maintenance performed and what are common maintenance items?

Routine maintenance includes lubrication of bearings and chains, cleaning forming rollers, checking blade conditions, tightening fasteners, and periodic inspection of electrical and hydraulic systems. Follow the supplier’s maintenance schedule for best results.

13. What safety features does the machine include?

Typical safety features include emergency stop buttons, protective guards/covers over moving parts, electrical protections, and PLC-controlled safe stopping. Additional safety measures can be specified per local regulations.

14. How long does it take to manufacture and deliver the machine?

Lead time depends on model complexity and customization. Typical delivery times are in the range of 30–60 days after order confirmation, but confirm current lead times with the supplier.

15. How do I get an accurate quote and what information should I provide?

To receive an accurate quote, provide desired panel profile drawings or samples, material type and thickness, finished panel width and length requirements, annual production targets, voltage/frequency for your location, and any required extras (decoiler, cut-off, stacking).

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading