B21, China Town Mall, Midrand

Fish Feed Machine: Floating Fish Feed Extruder

- Section : Machinery

- Category : Agriculture Machinery

- SKU : 1600987404772

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 27 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is a Floating Fish Feed Extruder and what does it do?

A Floating Fish Feed Extruder is an industrial machine that cooks and compresses feed ingredients under heat and pressure to form uniform pellets that float on water. It produces feed for fish, shrimp, crabs and some pets in a variety of sizes, shapes and nutrient formulations to improve feed intake, growth and feed conversion.

2. What species and feed types can this machine produce?

The extruder is used for fish (e.g., catfish, tropical fish), shrimp, crab and pet feeds (dogs, cats, tortoises, frogs). By changing molds and recipes it can produce micro feed for fry up to large pellets for adult fish and other aquatic animals.

3. What pellet sizes and shapes can be made?

Pellet diameter can be adjusted typically from about 0.4 mm up to 15 mm by switching dies and adjusting processing parameters. Shapes can include round, ring, and custom profiles depending on the mold used.

4. How does the extruder make pellets float?

Floating pellets are produced by a combination of high-temperature, high-pressure extrusion and rapid pressure release at the die which expands starch and creates a porous structure. Product formulation (starch level, oil content, binders) and extrusion parameters determine buoyancy and sinking time.

5. What raw materials can be used in the machine?

Common raw materials include fish meal, soybean meal, corn, wheat, rice bran, cassava/starch, blood meal, algae, vitamins/minerals and oils. Binders and pellets enhancers (e.g., wheat flour, cassava starch) are often used to get desired texture and floatability.

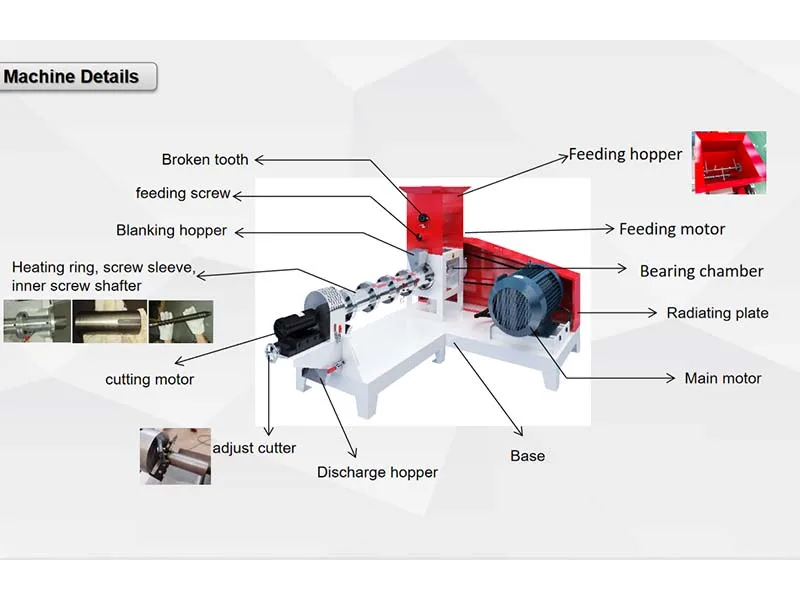

6. What are the main working components and principle of operation?

Key components are the feeding system, screw (single-screw), barrel, heater, die/cutter and motors. The screw conveys, mixes and cooks raw materials under heat and shear; the cooked mass is forced through a die where it expands and is cut into pellets by a rotating cutter.

7. What production capacities and model options are available?

Models cover a wide range from about 40 kg/h up to 800 kg/h and higher. Example capacities from the product range include 40–100 kg/h (Φ400–Φ500 screws), 160–300 kg/h (Φ600–Φ800), 380–600 kg/h (Φ900–Φ1200) and 750–800 kg/h (Φ1350). Choose a model based on required throughput.

8. What power requirements and dimensions should I expect?

Main motor power ranges from around 5.5 kW on small units to 75 kW on the largest models; feeder and cutter motors add additional kW. Machine footprints vary (examples: 1400×1030×1200 mm for small models up to 2470×2060×1650 mm for large ones). Exact power and size depend on chosen model.

9. Can I control pellet density, hardness and sinking time?

Yes. Adjusting the formulation (starch/oil/binder ratios), screw speed, temperature and die size controls density and texture. Higher expansion and lower density produce longer-floating pellets; increasing protein/oil or reducing expansion yields denser or slowly sinking pellets.

10. What downstream equipment is recommended after the extruder?

Typical downstream equipment includes a cooler to reduce pellet moisture and temperature, a dryer for moisture control and shelf life, a rotary coating machine for oil/vitamin coating, and sieves for grading pellet sizes.

11. How often should I perform maintenance and what are common maintenance tasks?

Daily cleaning of the feed path, regular lubrication of bearings and gearbox, periodic inspection of the screw, barrel and die for wear, and replacement of worn cutters and molds are recommended. Major service intervals depend on usage but a full service every 6–12 months is common.

12. What raw material preparation is required (moisture, particle size)?

Raw ingredients should be ground to a suitable particle size for consistent extrusion (typically <400 mesh for fine formulations) and pre-mixed. Moisture content of the mix before extrusion typically ranges from 12%–18% depending on recipe and machine; steam or liquid addition may be used in some setups.

13. What common production problems might occur and how to troubleshoot them?

Common issues: pellets crumble—check insufficient cook/pressure or wrong binder; pellets sink—reduce density by increasing starch or extrusion expansion; low output—check screw speed, feed rate and motor load; uneven pellets—inspect die/cutter wear and raw material consistency. Adjust process parameters and replace worn parts as needed.

14. Are spare parts, molds and technical support available?

Yes. Molds/dies, cutters, screws and other wear parts are normally available from the manufacturer or supplier. Most suppliers provide installation support, training, operation manuals and after-sales service for commissioning and troubleshooting.

15. What installation, power supply and safety considerations are required?

Installation needs a flat, level foundation with adequate space for machine dimensions and service access. Ensure correct three-phase power supply sized to the machine main and auxiliary motors, proper grounding and overload protection. Follow lockout/tagout and guarding procedures for safe operation, and provide operator training.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading