B21, China Town Mall, Midrand

Fish Farming Pressure Rotary Drum Filter

- Section : Machinery

- Category : Chemical Machinery

- SKU : 1601158310543

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

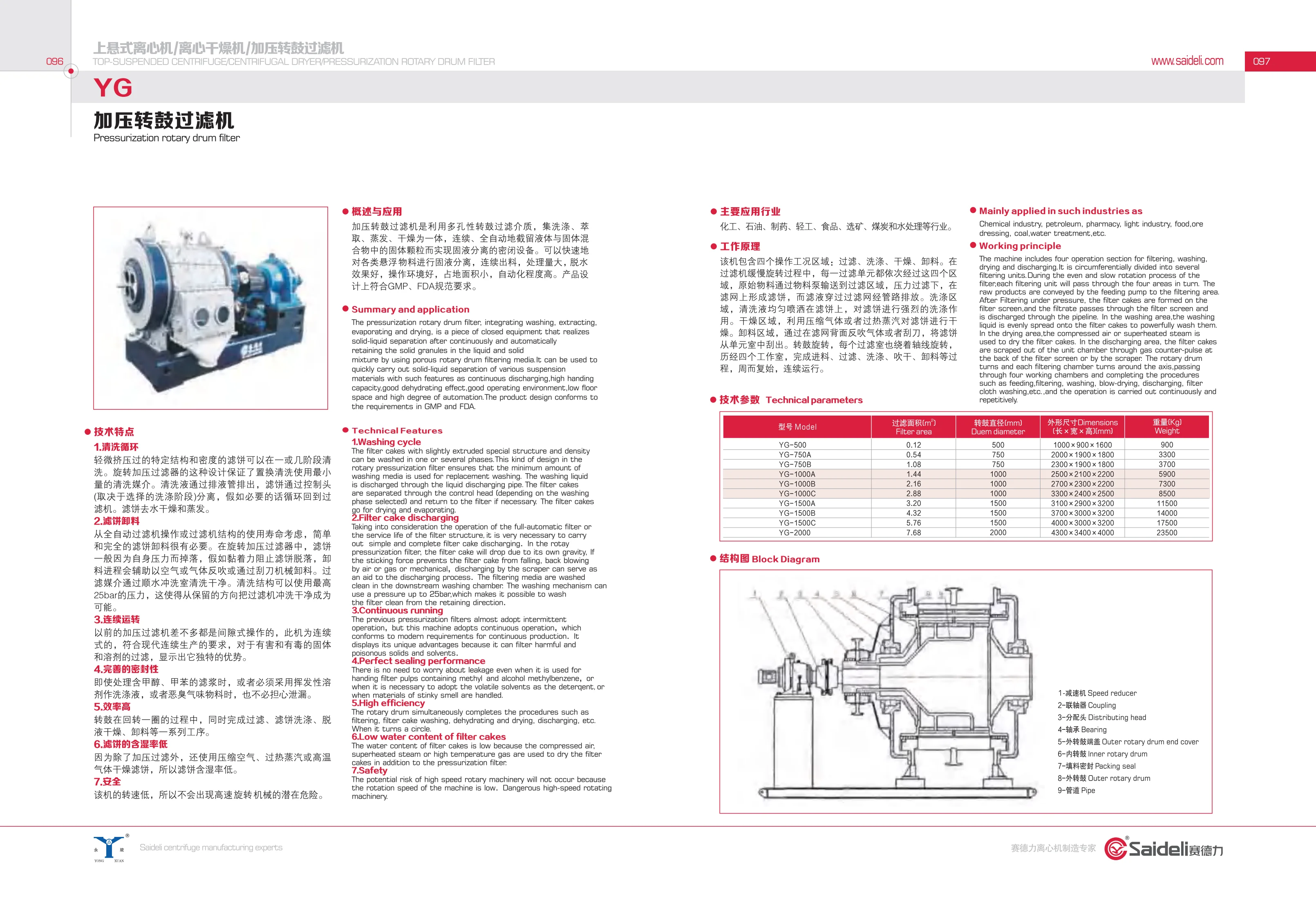

1. What industries can benefit from using the YG Rotary Drum Filter?

The YG Rotary Drum Filter is widely used in pharmaceuticals, chemicals, petroleum, food processing, and water treatment industries.

2. How does the YG Rotary Drum Filter ensure continuous operation?

The YG Rotary Drum Filter is designed for continuous operation, allowing for uninterrupted solid-liquid separation, which is ideal for modern production needs.

3. What are the advantages of the washing cycle in the YG Rotary Drum Filter?

The YG Rotary Drum Filter uses minimal washing media and allows for the recycling of the washing liquid, reducing waste and improving efficiency.

4. How is the filter cake discharged from the YG Rotary Drum Filter?

The filter cake is discharged either through its own pressure, aided by air/gas back blowing, or by mechanical scrapers, ensuring a clean and efficient discharge process.

5. Can the YG Rotary Drum Filter handle volatile substances?

Yes, the YG Rotary Drum Filter is designed with perfect sealing to handle materials like methanol, toluene, and other volatile solvents without leakage.

6. What is the efficiency of the YG Rotary Drum Filter?

The YG Rotary Drum Filter operates with high efficiency by simultaneously performing filtration, cake washing, dehydration, drying, and discharging.

7. How does the YG Rotary Drum Filter achieve low moisture content in the filter cake?

The filter uses compressed air, superheated steam, or high-temperature gas to dry the cake, ensuring minimal moisture content.

8. What safety features does the YG Rotary Drum Filter have?

The low-speed operation of the YG Rotary Drum Filter eliminates risks associated with high-speed rotating machinery, enhancing safety during operation.

9. What are the dimensions of the YG Rotary Drum Filter models?

The YG Rotary Drum Filter comes in various models with different dimensions. For example, the YG-500 model has a size of 1000 x 1800 x 2400 mm, while the YG-2000 model measures 6500 x 3000 x 3600 mm.

10. What is the weight of the YG Rotary Drum Filter models?

The weight varies by model. For instance, the YG-500 model weighs 900 kg, while the larger YG-2000 model weighs 32000 kg.

11. Is the YG Rotary Drum Filter compliant with industry standards?

Yes, the design of the YG Rotary Drum Filter meets rigorous standards of GMP and FDA, ensuring it is suitable for use in regulated industries.

12. How does the YG Rotary Drum Filter improve operational efficiency?

By integrating multiple processes like filtration, washing, and drying in a single operation, the YG Rotary Drum Filter significantly enhances operational efficiency.

13. What capacities are available for the YG Rotary Drum Filter?

The YG Rotary Drum Filter is available in various capacities, ranging from 0.125 m² filter area in the YG-500 model to 7.68 m² in the YG-2000 model.

14. Can the YG Rotary Drum Filter be customized for specific processes?

Yes, the YG Rotary Drum Filter can be customized based on specific processing needs, including adjustments to the washing cycles and discharge mechanisms.

15. What maintenance is required for the YG Rotary Drum Filter?

Regular maintenance includes checking seals, cleaning the drum, and ensuring the recycling system functions properly to maintain optimal performance.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading