B21, China Town Mall, Midrand

Feed Pellet Making Machine (210) with 4mm and 8mm Grinding Disc sldb

- Section : Machinery

- Category : Other Agricultural Equipment

- SKU : 1601020939632

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

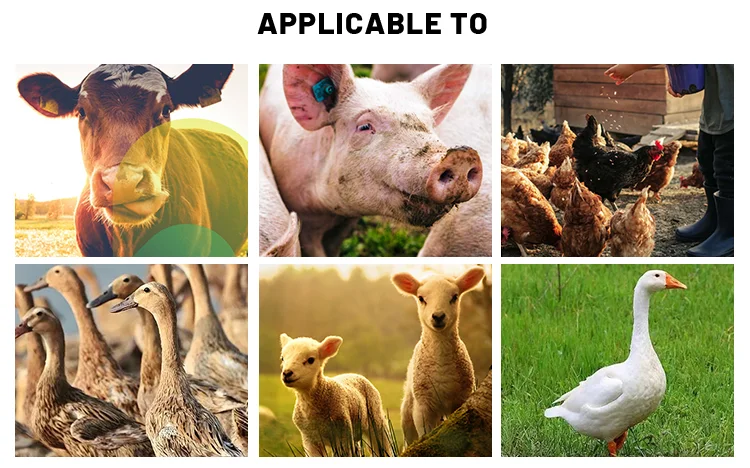

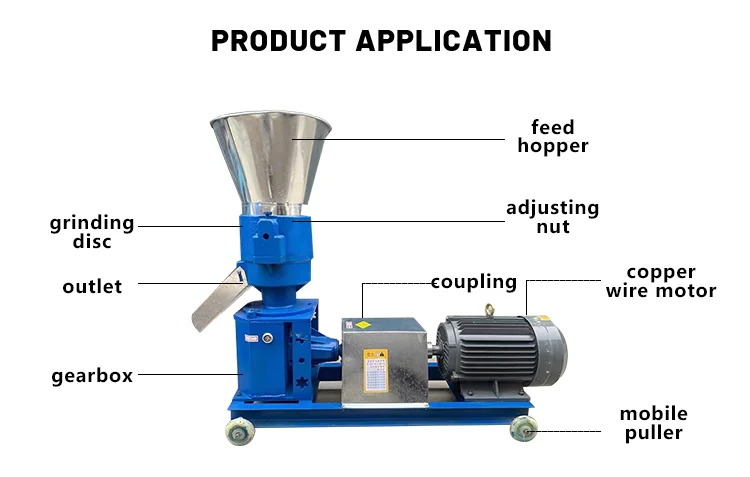

1. What is the Feed Pellet Making Machine (210) with 4mm and 8mm Grinding Disc sldb?

It's a pellet press machine in the JU series (model JU-210) designed to make animal feed pellets. This unit includes interchangeable 4mm and 8mm grinding/pelletizing discs for producing small and medium pellet diameters.

2. What are the key specifications for model JU-210?

Model JU-210 weighs about 170 kg, has a motor power of 7.5 kW, typical voltage 380 V, recommended water addition 8%, and an output capacity of approximately 300–400 kg per hour.

3. Which other models are available in the series and how do capacities differ?

The series includes JU-150, JU-160, JU-180, JU-210, JU-230, JU-260, and JU-300. Capacity increases with model size: roughly 80–100 kg/h (JU-150) up to 900–1200 kg/h (JU-300), with intermediate steps shown in the product parameters.

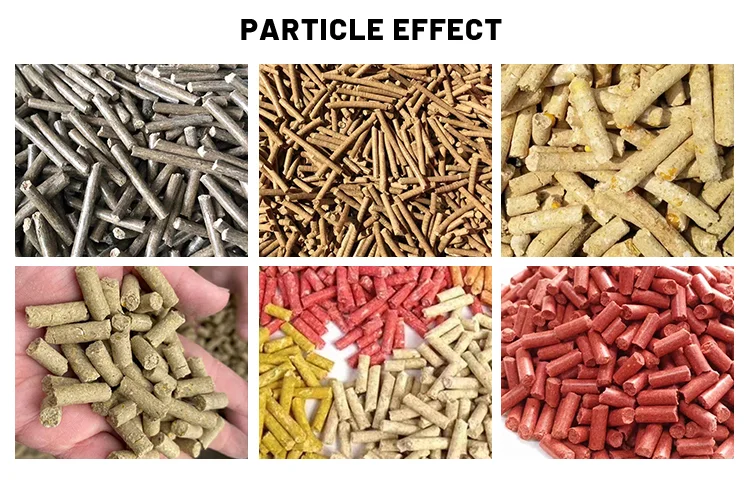

4. What pellet diameters can I produce with the included discs?

Using the supplied grinding/pelletizing discs you can produce pellets of approximately 4 mm and 8 mm diameter. Discs may be swapped to change pellet size.

5. What types of raw materials can this machine process?

Common materials include crushed grains (corn, wheat, barley), soybean meal, grass and alfalfa powder, feed premixes, and other similar dry feed ingredients. Materials should be properly milled and blended before pelleting.

6. What moisture content is recommended for raw materials?

The product parameters indicate an 8% water addition is recommended. Aim for material moisture appropriate for pelleting—typically adjust with about 8% added water or as advised after testing your specific formulation.

7. What power and electrical requirements does JU-210 need?

JU-210 requires a 7.5 kW motor and is typically supplied for 380 V (three-phase). Other models may support 220 V/380 V options (e.g., JU-160). Confirm with the supplier for your local electrical configuration.

8. How do I change between the 4mm and 8mm discs?

Turn off and isolate power, open the pelletizing chamber according to the manual, remove the current disc and replace it with the desired-sized disc. Ensure proper alignment and secure fasteners before restarting. Refer to the supplied manual for detailed steps and safety precautions.

9. What maintenance is required and how often?

Regular maintenance includes daily cleaning of the chamber and dies, lubrication of bearings and moving parts per the manual, checking belt tension and motor mounts, and inspecting dies/discs for wear. Replace worn dies/discs as needed. Follow the manufacturer's maintenance schedule for intervals.

10. Is installation and setup provided?

Basic installation (placement, electrical connection, and initial adjustment) can usually be handled by your local technician. Some suppliers offer installation assistance or a setup guide—confirm with the vendor for onsite service or remote support options.

11. What safety features should I be aware of?

Standard safety measures include emergency stop, proper guarding of moving parts, overload protection on the motor, and grounding of electrical components. Always isolate power before maintenance and follow the operator manual and local safety regulations.

12. What spare parts and consumables should I keep on hand?

Common spares include dies/discs (4mm and 8mm), rollers, bearings, belts, gaskets, and drive components. Keeping at least one spare die/disc and basic wear parts reduces downtime.

13. How noisy is the machine and are there recommended operating conditions?

Pellet machines produce moderate operational noise typical of mechanical presses and motors. Use in a ventilated, dry area on a stable foundation and follow recommended feed particle size and moisture levels for best results.

14. What does 'sldb' mean and are customizations available?

'sldb' appears to be a model/code suffix used by the manufacturer or supplier. For clarification and available custom options (different voltages, additional die sizes, feed hoppers, or conveyor attachments), contact the supplier or manufacturer directly.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading