B21, China Town Mall, Midrand

Earth Mud Clay Eco Adobe Interlocking Block Brick Making Machine

- Section : Machinery

- Category : Brick Making Machinery

- SKU : 1601036404073

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 01 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Earth Mud Clay Eco Adobe Interlocking Block Brick Making Machine?

It is a manual interlocking block and brick molding machine (model LG2-40) designed to produce eco-friendly earthen, clay, mud, and adobe interlocking blocks without cement. It forms a variety of block sizes and is intended for small- to medium-scale production.

2. What is the machine's production capacity?

Rated production capacity is about 2,500 pieces per 8-hour shift (actual output depends on operator speed, material preparation, and block drying time).

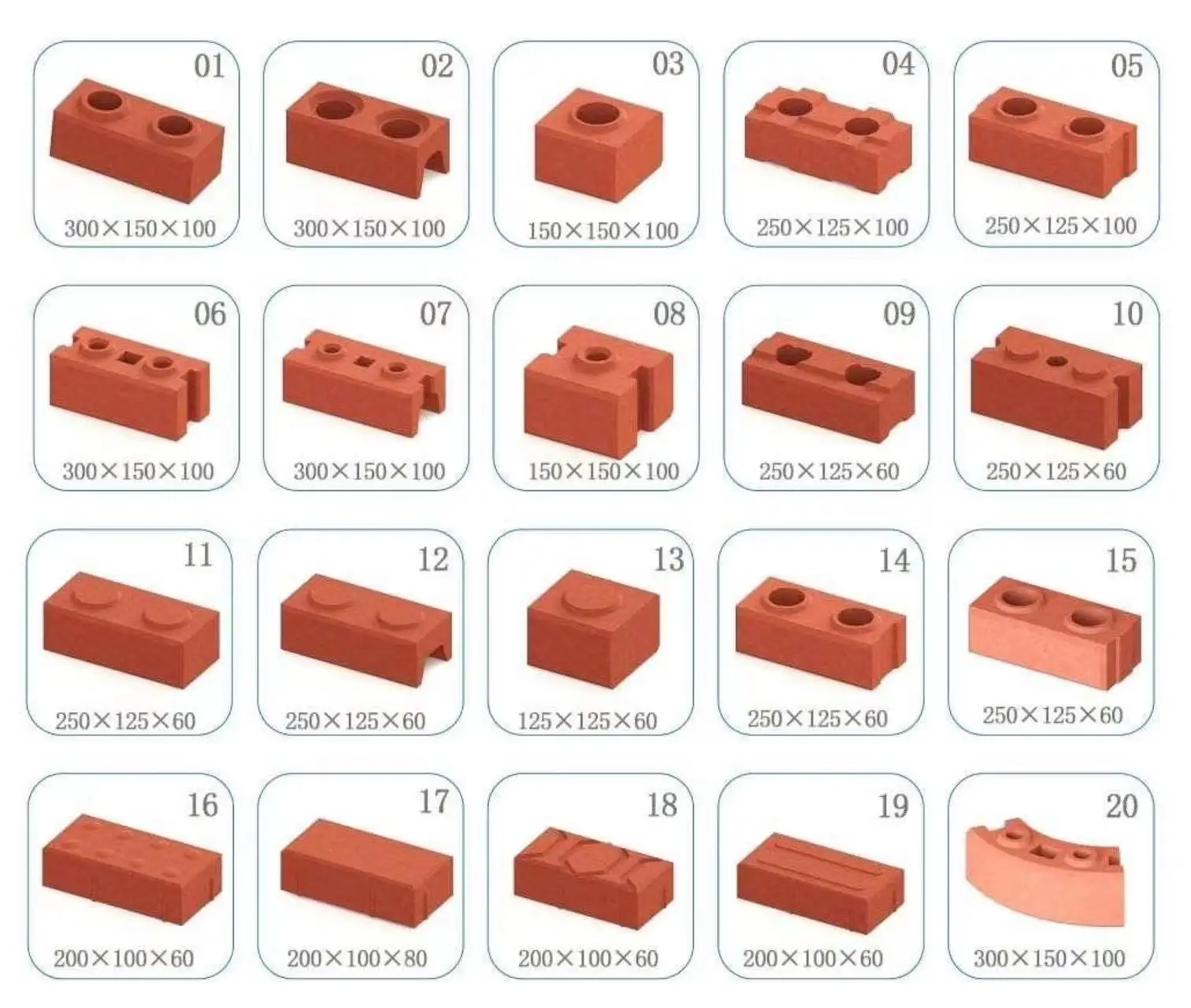

3. What block sizes can this machine produce?

It supports many common sizes including 150×150×100 mm, 200×100×60 mm, 200×200×60 mm, 230×220×115 mm, 240×115×90 mm, 300×150×100 mm, 400×100×200 mm, 400×120×200 mm, 400×150×200 mm and 400×200×200 mm. Molds are changeable to produce different sizes.

4. What raw materials can be used?

Designed for clay, mud, soil and earth (adobe). It is optimized for earthen mixes; recommended mix proportions and any additives should be tested locally and confirmed with the supplier.

5. How does the machine operate and what power is required?

The LG2-40 uses manual pressure operation (pressure: manual). No electrical power is required in the standard configuration. Motorized or hydraulic options may be available on request—contact the supplier for customization.

6. What is the machine's cycle time per mould?

The molding cycle is approximately 20 seconds per operation. Actual cycle time will vary with operator efficiency and mold change operations.

7. What are the machine dimensions and weight?

Overall dimensions are 1500 × 620 × 1400 mm (L × W × H) and the machine weighs approximately 280 kg.

8. What is the expected lifespan and warranty?

The machine has an expected lifespan of around 10 years with proper maintenance. Warranty is 1 year for the machine and 1 year for core components (pressure vessel).

9. What certifications does the machine have?

This model carries CE and ISO9001 certifications.

10. What maintenance is required?

Regular maintenance includes cleaning molds and surfaces after use, checking and tightening fasteners, lubricating moving parts per supplier guidance, inspecting the pressure vessel and wear parts, and replacing worn moulds or seals as needed.

11. Are spare parts and molds available?

Yes—standard spare parts and replacement molds are available from the manufacturer or distributor. It's recommended to order common wear parts (e.g., mold inserts, seals) for quick replacement.

12. What are the packaging and shipping details?

Packaging and shipping depend on order size and destination. The machine is typically crated for export. Contact the supplier for packing list, freight options, and FOB/CIF quotations.

13. Does the machine produce interlocking blocks that require curing?

Yes. Although blocks are formed on the machine, earthen blocks generally require controlled drying (air-drying or shaded drying) and sometimes stabilization depending on the mix. Curing and drying time depend on climate, mix, and thickness—follow supplier recommendations for best strength and durability.

14. Can the machine be customized (color, block shape, automation)?

Some customization is possible—different mold shapes/sizes, optional color coatings or surface finishes, and upgraded motorized or hydraulic systems may be offered. Contact the manufacturer to discuss specific customization needs.

15. What site conditions and operator skills are needed?

A level, stable working area is recommended. Since this is manually operated, trained operators are required for consistent output; supplier typically provides basic operation and maintenance guidance or training. No special electrical infrastructure is required for the standard manual model.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading