B21, China Town Mall, Midrand

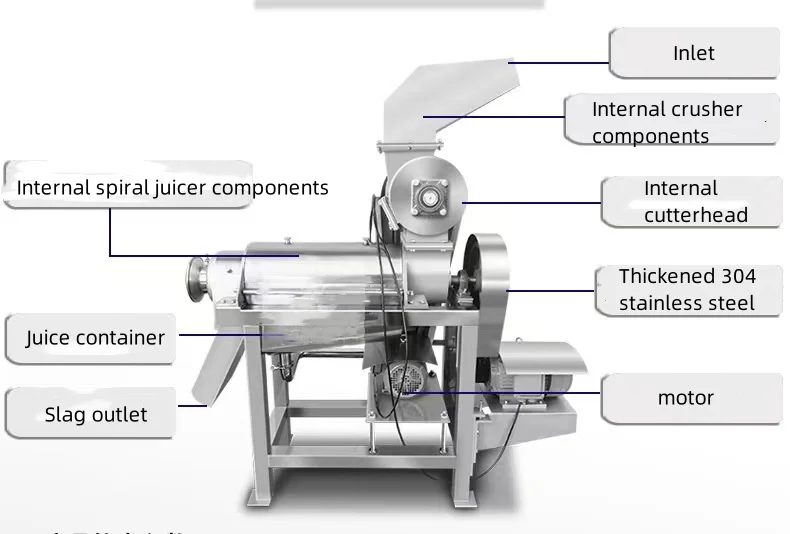

DRB-PS0.5T Orange Juice Extractor Machine (500kg/H)

- Section : Machinery

- Category : Juice Extractors

- SKU : 1601097792053

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 01 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the maximum juice extraction capacity of the DRB-PS0.5T Orange Juice Extractor Machine?

The DRB-PS0.5T Orange Juice Extractor Machine has a maximum juice extraction capacity of 500 kg/h.

2. How does the automatic water slag separation feature work?

The automatic water slag separation feature allows for the efficient separation of juice from pulp, ensuring a high juice yield without manual intervention.

3. What is the power requirement for the DRB-PS0.5T machine?

The DRB-PS0.5T machine requires a power supply of 3+2.2 kW.

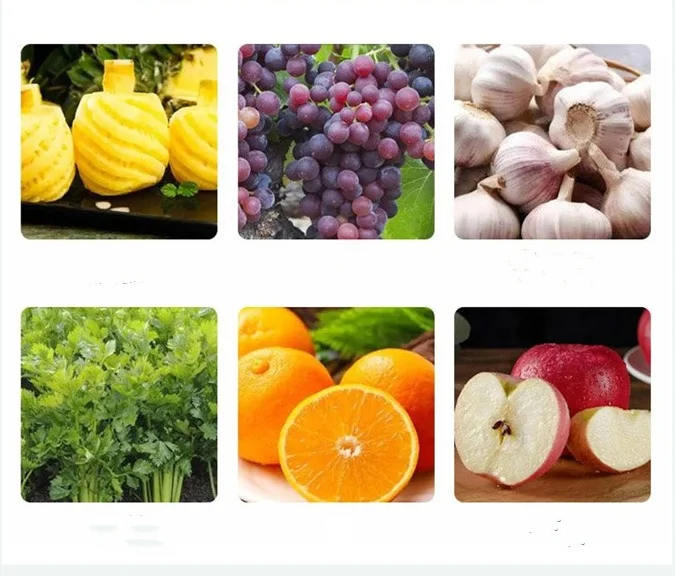

4. What type of fruits and vegetables can be processed with this machine?

The DRB-PS0.5T is designed to process a variety of fruits and vegetables, particularly citrus fruits like oranges, but can also handle others with similar textures.

5. How does the spiral juicing system improve juicing results?

The spiral juicing system gradually decreases in pitch while increasing in diameter, which helps to squeeze the material more effectively and improve juice extraction results.

6. What are the dimensions of the DRB-PS0.5T machine?

The dimensions of the DRB-PS0.5T machine are 1100 mm x 450 mm x 1550 mm.

7. Can the machine handle large quantities of fruit at once?

Yes, the machine is designed for high throughput, capable of processing up to 500 kg of fruit per hour.

8. What maintenance is required for the DRB-PS0.5T Orange Juice Extractor Machine?

Regular maintenance includes cleaning the components after use, checking for wear on the blades, and ensuring that the motor and moving parts are lubricated.

9. Is the DRB-PS0.5T suitable for commercial juice production?

Yes, the DRB-PS0.5T is well-suited for commercial juice production due to its high capacity and efficient extraction features.

10. What is the material of the juice container?

The juice container is typically made from food-grade stainless steel, ensuring durability and hygiene.

11. How is the juice filtered in this machine?

The machine features a built-in filter that allows the juice to pass through while separating any pulp or solid material.

12. What safety features does the DRB-PS0.5T include?

The machine includes safety features such as automatic shut-off mechanisms and protective covers to prevent accidents during operation.

13. Can the gap size for slag discharge be adjusted?

Yes, the axial movement of the pressure regulating head allows for the adjustment of the gap size for optimal slag discharge.

14. What is the feed inlet size for the machine?

The feed inlet size for the DRB-PS0.5T is designed to accommodate large pieces of fruit to facilitate easier feeding into the juicer.

15. Is training provided for operating the machine?

Training may be provided upon purchase; please inquire with the supplier for specific training options available.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading