B21, China Town Mall, Midrand

CY-MACH Mine Vibrating Feeder with Vibration Motor of Bowl Feeder

- Section : Machinery

- Category : Mining Machinery

- SKU : 1601013757903

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the CY-MACH Mine Vibrating Feeder and what is it used for?

The CY-MACH Mine Vibrating Feeder is an electric-powered linear vibrating feeder designed to feed mining materials (ores, stones, gravel) continuously and uniformly to crushers, conveyors, vibrating screens and other processing equipment. It is used in mining, quarrying, construction, recycling and other heavy material handling applications.

2. What is the feeding capacity range of this feeder?

The feeder handles high volumes with a capacity range of approximately 90 to 1000 tons per hour, depending on the model and material properties.

3. What type of vibration motor does the feeder use and what is its speed?

The unit is equipped with a vibration motor of the bowl-feeder type. Operating speed is high frequency in the range of about 600–850 rpm to ensure steady and controllable material flow.

4. How do I choose the right model for my operation?

Select a model based on required throughput (t/h), maximum feed particle size, and the downstream equipment feed opening. Provide your target capacity, maximum lump size and feed rate to the supplier to receive a recommended model and detailed datasheet.

5. Is the feeder customizable?

Yes. The CY-MACH feeder is available in various sizes and can be customized (dimensions, feed tray configuration, mounting options, and color) to fit specific plant layouts and material characteristics.

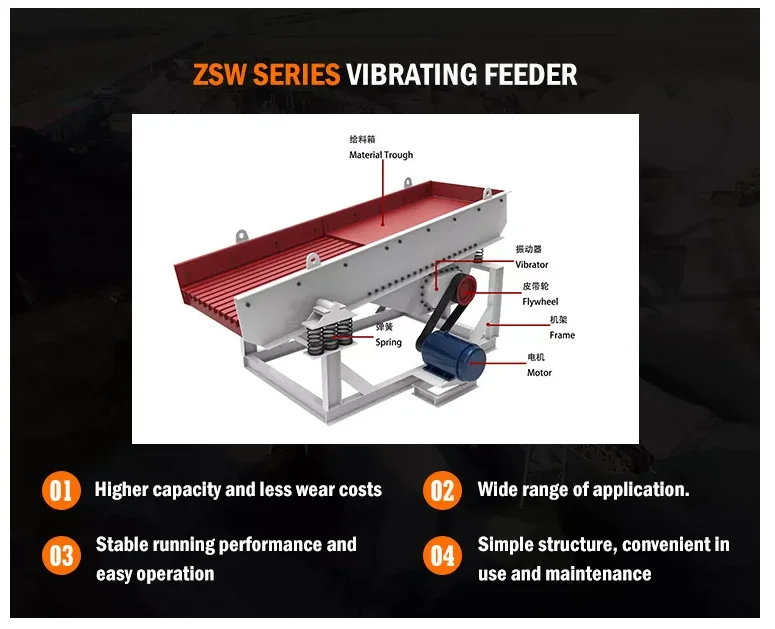

6. What are the main components of the vibrating feeder?

Key components include the feed spout (tray), vibration body, bowl-type vibrating motor, damping/suspension device, and replaceable guard plates/grids for screening and wear protection.

7. How is feed rate adjusted?

Feed rate is adjusted by changing the exciting force and vibration amplitude of the motor, and by adjusting grid clearance when provided. These adjustments allow continuous control of material flow to match process requirements.

8. What are the maintenance requirements and typical service intervals?

The feeder is designed for low maintenance. Routine checks include verifying fasteners, motor mounts, spring/damping elements, and wear plates. Lubrication and motor service intervals depend on operating hours and site conditions; consult the supplied maintenance manual for a recommended schedule.

9. What spare parts should I keep on hand?

Recommended spare parts include vibrating motors (or motor components), springs/dampers, wear/guard plates, fasteners, and electrical components (starter/contactors). Exact spare-parts lists vary by model and duty; request a parts list with your order.

10. What is the warranty and after-sales support?

The product comes with a 3-year warranty and lifetime after-sale support for maintenance advice, spare parts supply and technical assistance.

11. Is installation and commissioning included?

Standard supply includes equipment, installation drawings and an operation manual. On-site installation and commissioning can be provided as an additional service—please request it when ordering.

12. Can the feeder handle abrasive or wet materials?

Yes. The feeder is built from durable materials and is suitable for abrasive and a range of moisture conditions. For highly abrasive or sticky materials, we recommend specific wear-resistant liners and special configurations—specify your material characteristics for the best solution.

13. How does the feeder integrate with other plant equipment?

The CY-MACH feeder is designed to feed belt conveyors, vibrating conveyors, bucket elevators, vibrating screens and crushers. Interface dimensions and feed heights can be customized to fit existing plant equipment.

14. What safety features are provided?

The feeder includes guarded motor mounts, replaceable wear plates, and provisions for emergency stops and electrical protection. Full safety integration depends on site requirements—additional guards and interlocks can be supplied on request.

15. How long is the delivery lead time and how is the unit shipped?

Lead time depends on model, customization and order size. Units are typically factory-packed for sea or road shipment. Provide your delivery location and order details to receive an accurate lead-time and shipping quotation.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading