B21, China Town Mall, Midrand

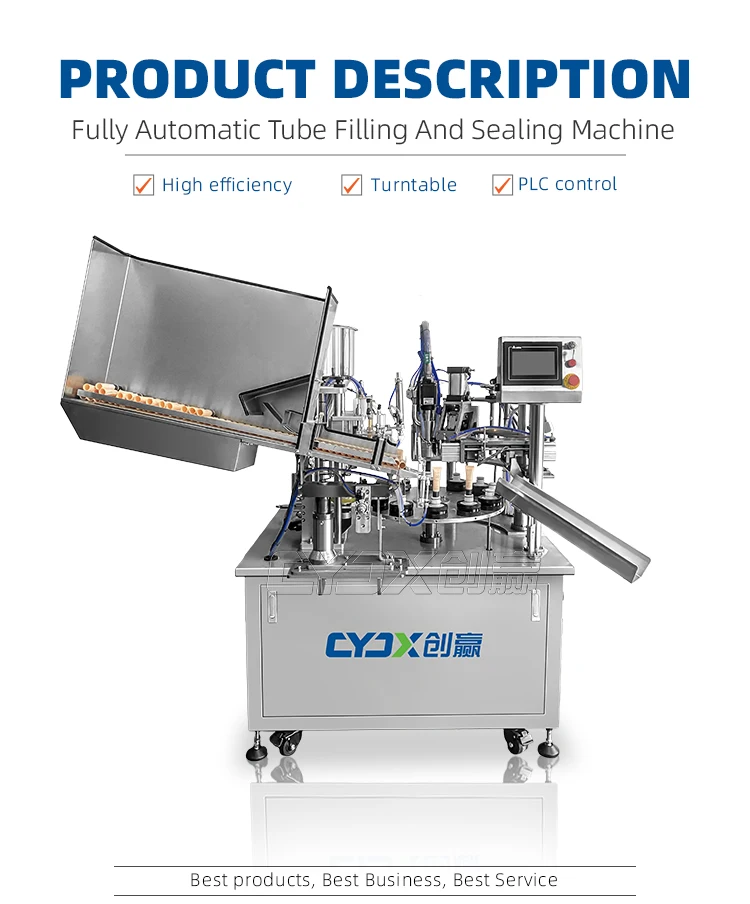

CYJX Automatic Plastic Laminated Soft Tube Filling Sealing Machine Cosmetic Cream Tube Filling Machine

- Section : Machinery

- Category : Laminating Machines

- SKU : 1601191266342

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 08 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What types of tubes can the CYJX Automatic Plastic Laminated Soft Tube Filling Sealing Machine handle?

The machine can handle plastic tubes, aluminum plastic tubes, and composite tubes.

2. What are the size specifications for the tubes that can be used with this machine?

The machine can accommodate various tube diameters; please provide your tube size specifications for customization.

3. How many tubes can this machine seal per hour?

The sealing capacity depends on your specific requirements and setup; please let us know your target output.

4. Does this machine come with a full production line solution?

Yes, we can supply a complete production line including the water treatment machine, filling machine, and labeling packing machine.

5. What is the main feature of the automatic ultrasonic tail-sealing mechanism?

The ultrasonic tail-sealing mechanism provides high-quality sealing for liquid and paste containers, ensuring efficient operation.

6. Can the control panel be customized for touchscreen operation?

Yes, we can modify the control panel to feature touchscreen capabilities if preferred.

7. What advantages does the filling nozzle provide?

The filling nozzle allows precise filling of materials and can include an air blowing cutting device for high viscosity products.

8. How does the automatic tube loader work?

The automatic tube loader consists of a loader and a tunnel that conveys tubes to the working disk automatically.

9. What types of products is this machine suitable for filling?

The machine is ideal for high viscosity products such as cosmetic creams and toothpaste.

10. What is the purpose of the inner and outer heating heads?

The heating heads are used to heat aluminum-plastic laminated tubes, allowing for faster temperature rise and sealing.

11. What is the sealing effect achieved by this machine?

The seal head presses the hot tube bottom to create a secure seal and can print if needed.

12. Is the machine suitable for high production efficiency?

Yes, the overall operation is designed to improve production efficiency and reduce labor intensity.

13. What should I do if I have specific requirements for my production line?

Please contact us with your specific requirements, and we will provide a tailored solution to meet your needs.

14. Can I get support for installation and setup of the machine?

Yes, we provide support for installation and setup as part of our customer service.

15. What safety features are included in the machine?

The machine includes an emergency stop button and other safety features to ensure safe operation.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading

Product Paramenters

Product Paramenters