B21, China Town Mall, Midrand

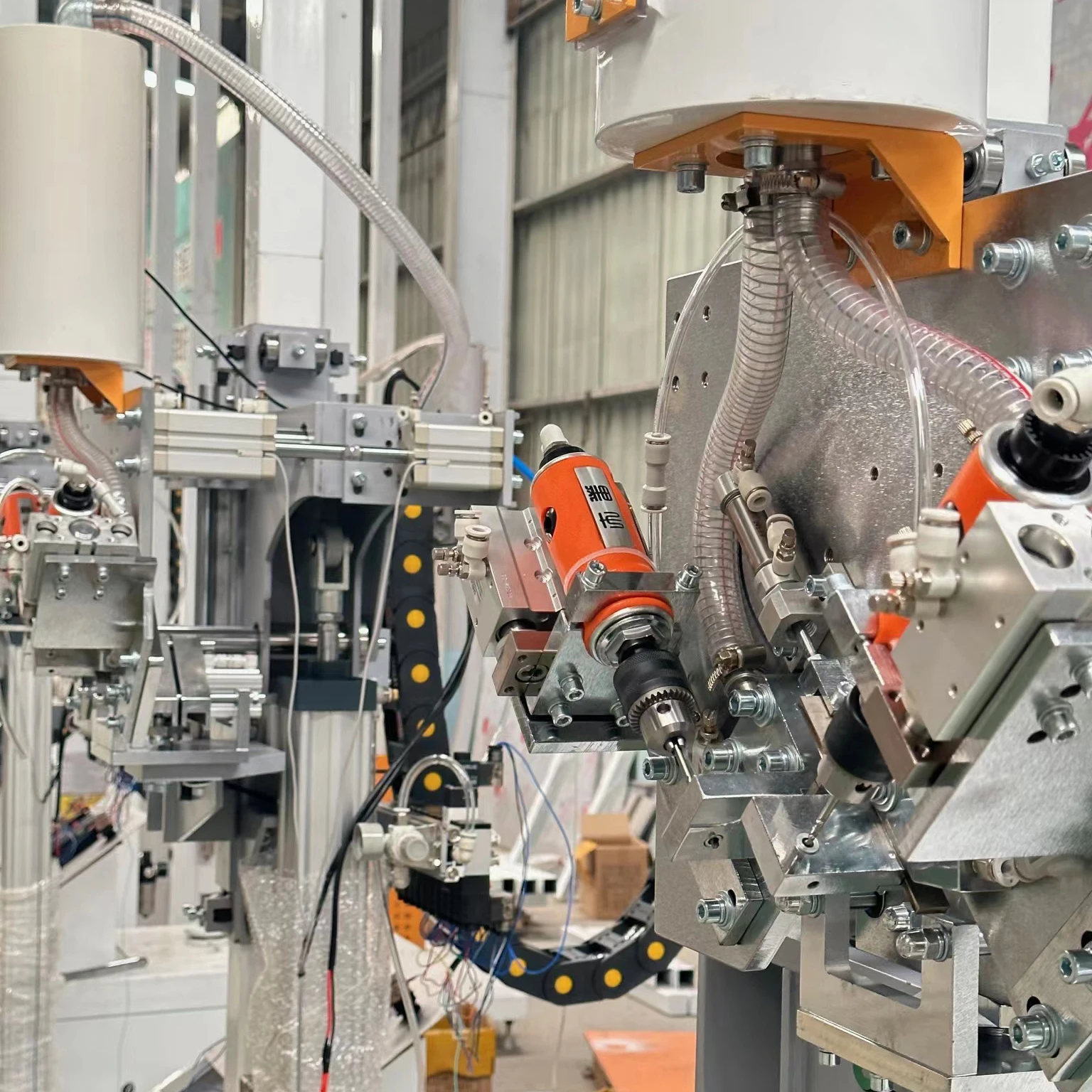

CNC Desiccant Filling Machine For Insulating Glass Production

- Section : Machinery

- Category : Manufacturing Machinery

- SKU : 1601163521187

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 28 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the primary function of the CNC Desiccant Filling Machine?

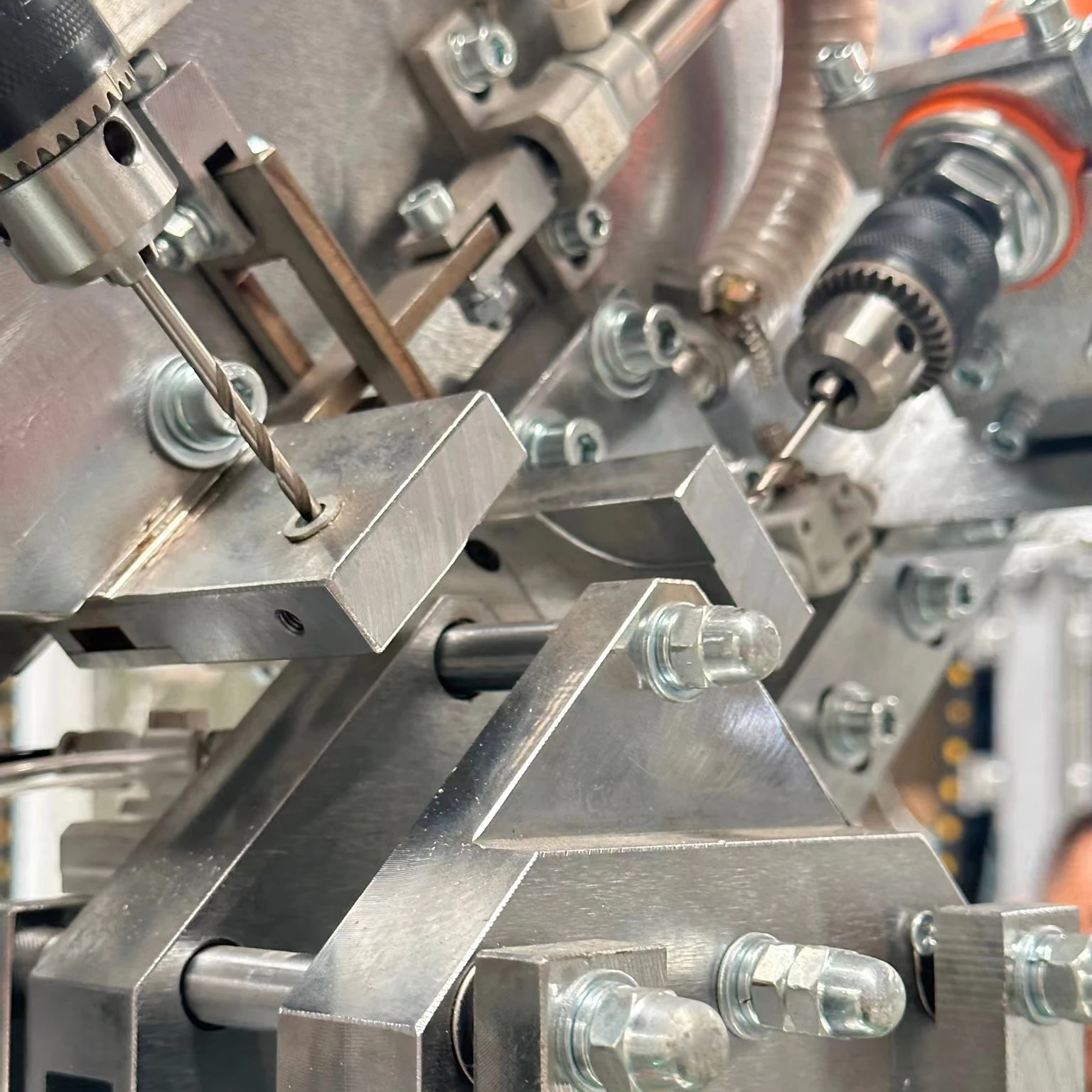

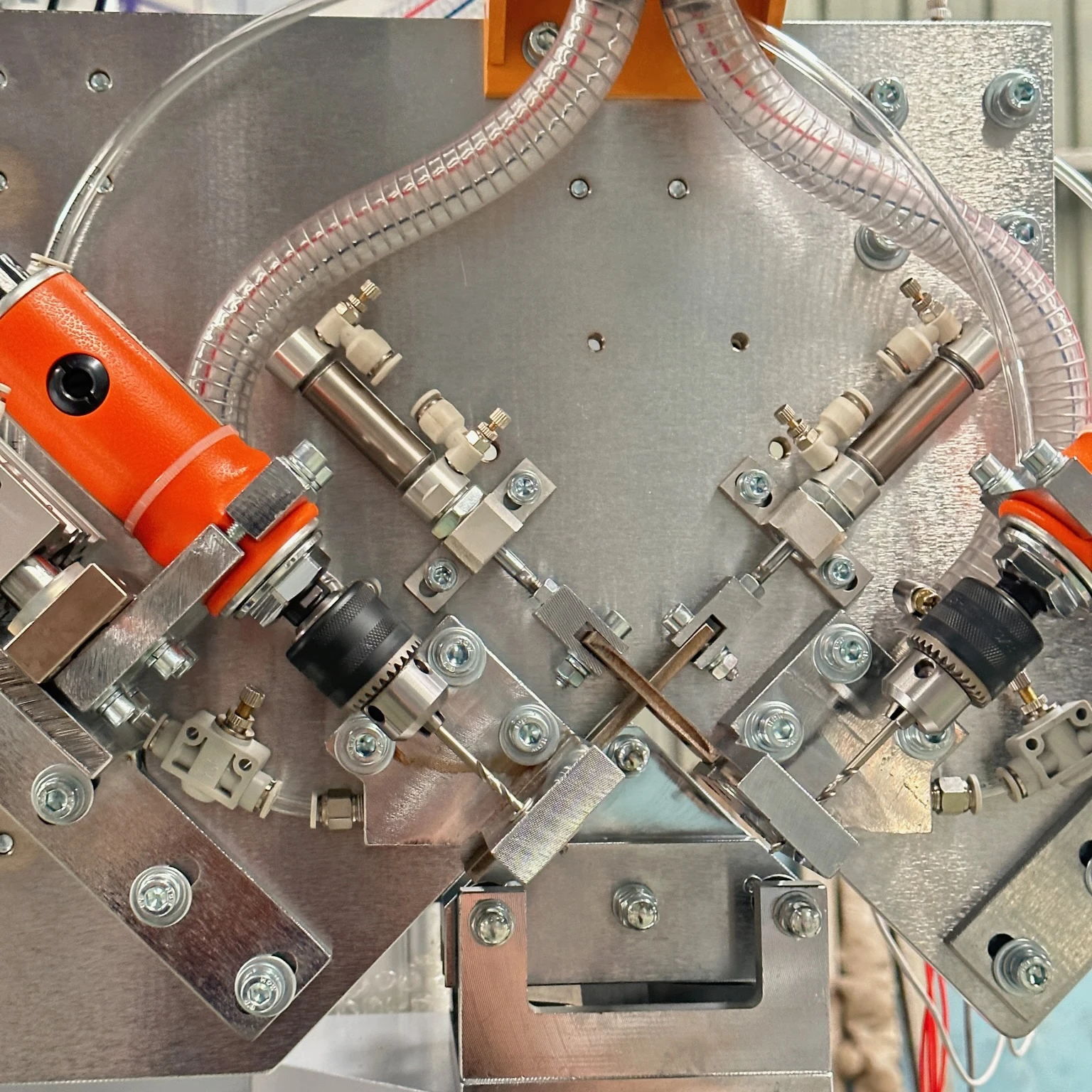

The primary function of the CNC Desiccant Filling Machine is to automate the drilling and filling of insulating glass with desiccant, improving efficiency and quality in the production process.

2. What are the key specifications of the YBKE Desiccant Filling Machine?

Key specifications include a power supply of 220V 50HZ, operating voltage of 5 KW, aluminum strip thickness of 6.5 mm, and dimensions of 850*1200*2850 mm.

3. How does the programmable controller (PLC) enhance the machine's performance?

The programmable controller (PLC) allows for automated drilling and canning operations, ensuring precise control and reducing manual labor requirements.

4. What types of aluminum frame sizes can the machine accommodate?

The machine features an adjustable head and a pneumatic lifting device, allowing it to accommodate various aluminum frame sizes efficiently.

5. What is the warranty period for the core components of the machine?

The core components of the machine come with a warranty period of 1 year.

6. Is the YBKE Desiccant Filling Machine suitable for both manufacturing and repair?

Yes, it is suitable for both manufacturing new insulating glass and repairing existing units.

7. What is the gross weight of the machine?

The gross weight of the YBKE Desiccant Filling Machine is 200 KG.

8. Are there video inspection reports available for the machine?

Yes, video outgoing-inspection reports are provided to ensure the quality and performance of the machine.

9. What is the molecular sieve particle size used in this machine?

The machine uses a molecular sieve particle size of 0.3 mm for effective desiccant filling.

10. How does the machine improve efficiency and quality in production?

The new drilling and filling process, along with automated controls and adjustable features, significantly enhances both efficiency and quality in insulating glass production.

11. Can the filling times be adjusted for different frame sizes?

Yes, the machine allows for pre-set filling times that can be adjusted according to different aluminum frame sizes.

12. What advantages does the liftable canning head provide?

The liftable canning head allows for easy adjustment and handling of different frame sizes, enabling efficient drilling and canning operations.

13. Is the machine designed for new installations or retrofitting existing setups?

The machine is designed for both new installations and can be integrated into existing setups to improve production capabilities.

14. What type of maintenance is required for the CNC Desiccant Filling Machine?

Regular maintenance should include checking the PLC functions, ensuring the pneumatic systems are operational, and inspecting the drilling and filling components for wear and tear.

15. Where can I purchase the YBKE Desiccant Filling Machine?

You can purchase the YBKE Desiccant Filling Machine through authorized distributors or directly from the manufacturer's website.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals