B21, China Town Mall, Midrand

Bullet Magnetic Separator Machine for Iron Impurities Removing

- Section : Machinery

- Category : Mineral Separators

- SKU : 1600593207660

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the purpose of the Bullet Magnetic Separator Machine?

The Bullet Magnetic Separator Machine is designed to remove iron impurities from liquid or semi-liquid materials, ensuring material purity and protecting equipment from contamination.

2. What materials are the Bullet Magnetic Separator Machines made of?

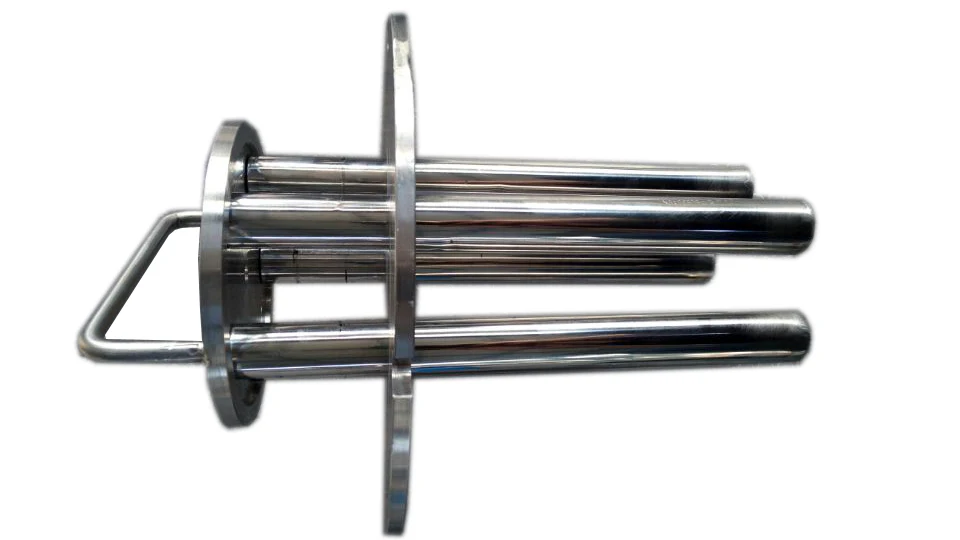

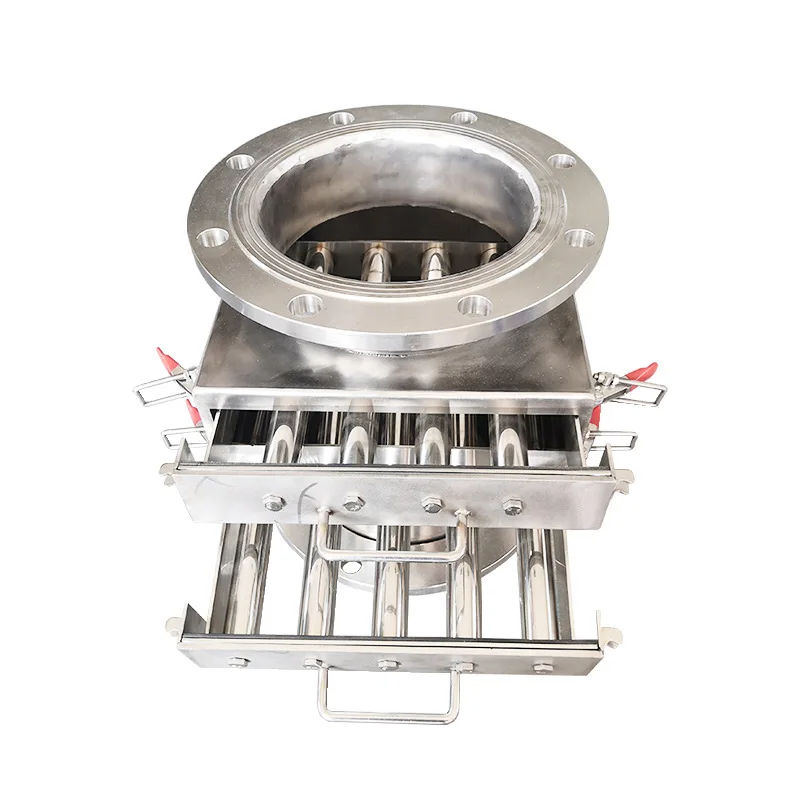

They are made entirely from high-quality stainless steel, specifically SUS 304 or 316, which provides excellent corrosion resistance and cleanliness.

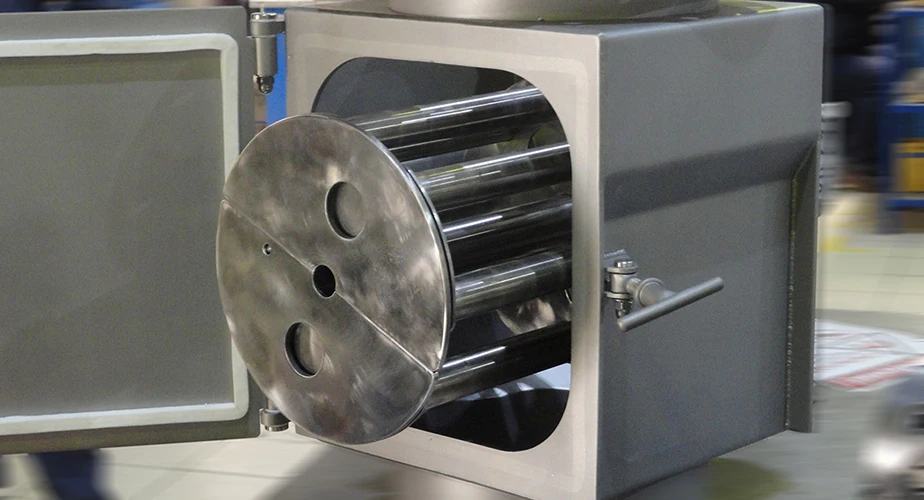

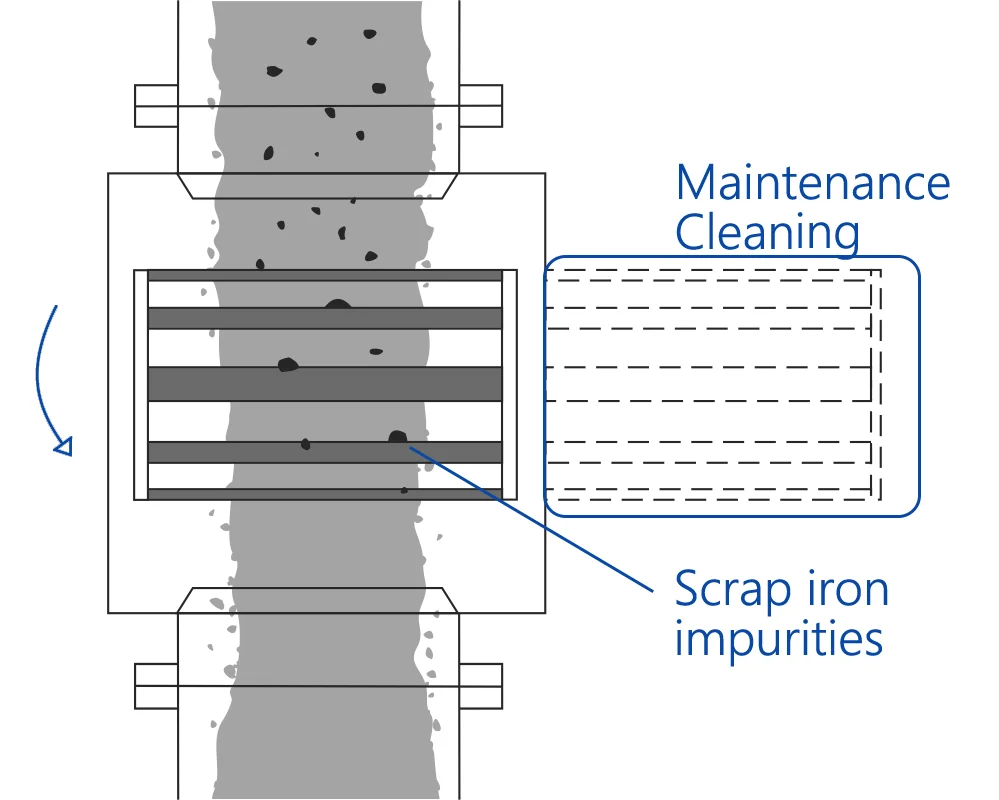

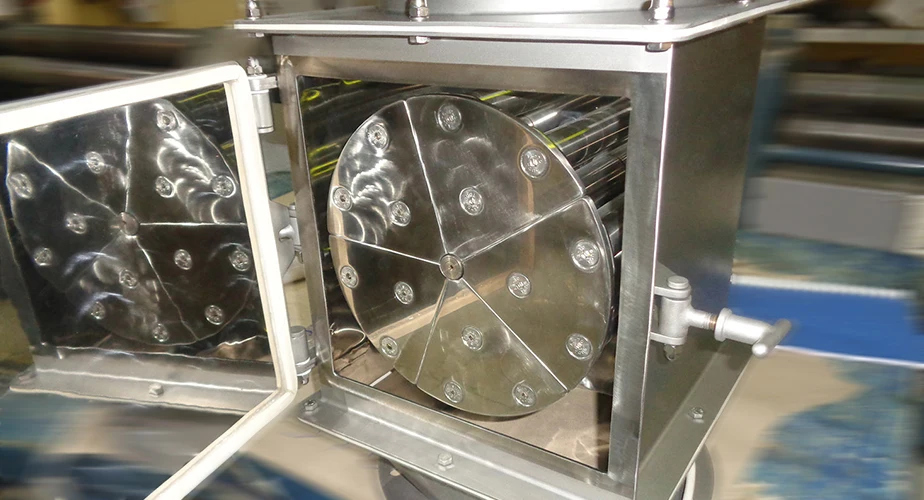

3. How does the magnetic separation process work?

The machine uses a series of spherical magnetic tubes that create a strong magnetic field. As the material flows through, it is forced to follow a zig-zag pattern, maximizing contact with the magnets and trapping metal impurities.

4. What types of materials can the Bullet Magnetic Separator handle?

The machine is suitable for various materials, including liquids and semi-liquids with different viscosities, as well as dry free-flowing products like sugar, grain, and tea.

5. Is the Bullet Magnetic Separator easy to install?

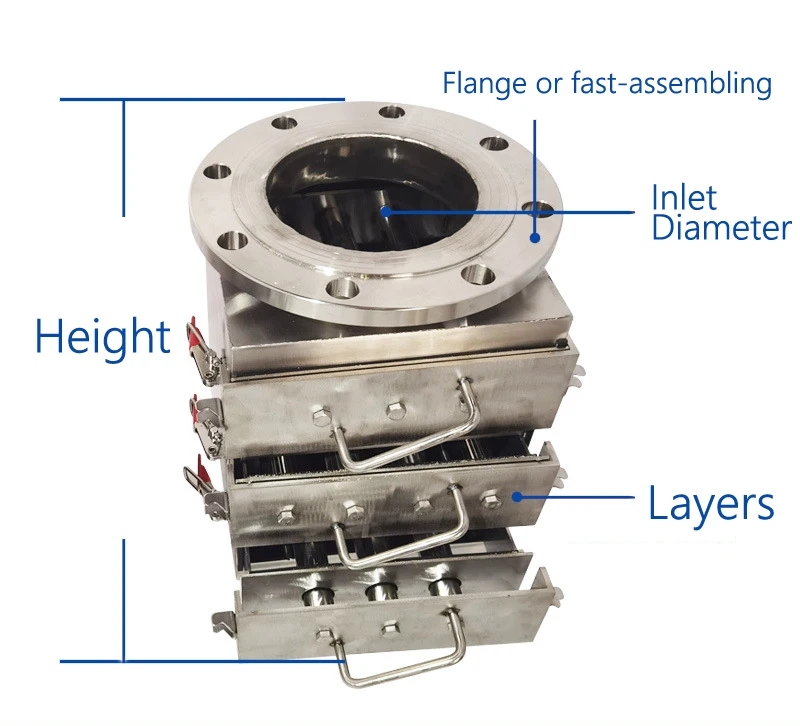

Yes, the machine features easy installation options with flanges and quick-release links, making it convenient to integrate into existing systems.

6. How often does the Bullet Magnetic Separator require maintenance?

Due to its permanent magnets, the separator requires minimal maintenance. However, periodic checks and cleaning of the magnetic components are recommended to maintain optimal performance.

7. What is the maximum operating temperature for the magnets?

The standard operating temperature is 80 degrees Celsius, but magnets can be specially made to withstand temperatures up to 350 degrees Celsius if needed.

8. Can the Bullet Magnetic Separator be customized for specific applications?

Yes, the separator can be customized to meet specific installation requirements, including different sizes, configurations, and housing types for pipelines.

9. What is the difference between N-style and E-style separators?

N-style separators are designed for standard operation, while E-style separators allow for easy cleaning by enabling quick removal of the magnetic cores from the housing.

10. How effective is the Bullet Magnetic Separator at removing metal impurities?

The separator is highly effective, capable of capturing even the smallest metal impurities due to its superior magnetic performance and optimal design.

11. What industries can benefit from using the Bullet Magnetic Separator?

Industries such as food processing, pharmaceuticals, and other manufacturing sectors that prioritize product purity and equipment protection can benefit from this separator.

12. Is the Bullet Magnetic Separator suitable for existing manufacturing lines?

Yes, the separator can be integrated as a stand-alone solution or incorporated into current manufacturing lines, pipelines, and hoppers.

13. What are the dimensions and weight options for the Bullet Magnetic Separator?

The Bullet Magnetic Separator comes in various models with different weights ranging from 159 kg to 352 kg, depending on the specific model chosen.

14. Do you offer support for installation and operation of the Bullet Magnetic Separator?

Yes, we provide support for installation and operation, ensuring that customers can effectively use the separator in their specific applications.

15. What is the expected lifespan of the Bullet Magnetic Separator?

With proper maintenance and care, the Bullet Magnetic Separator can provide many years of reliable service, thanks to its durable construction and materials.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading