B21, China Town Mall, Midrand

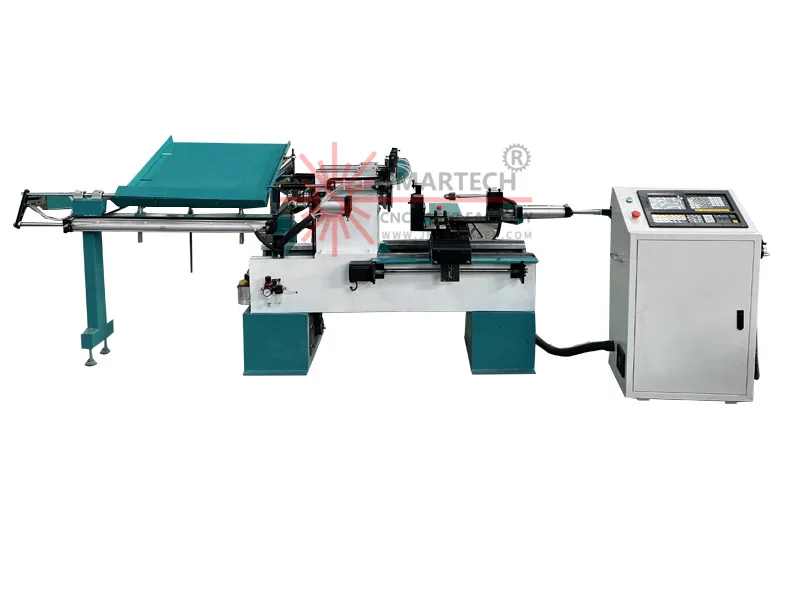

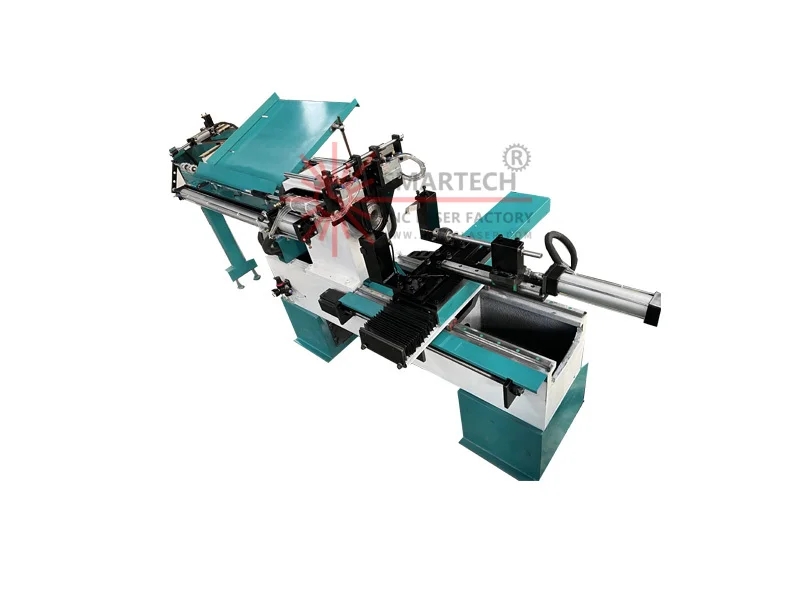

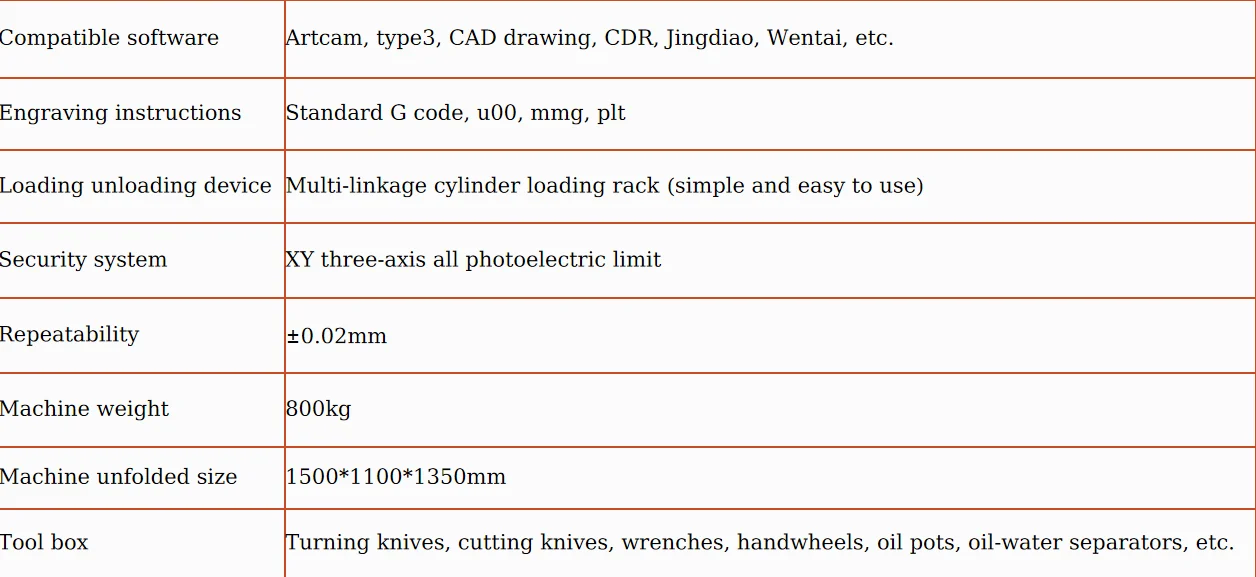

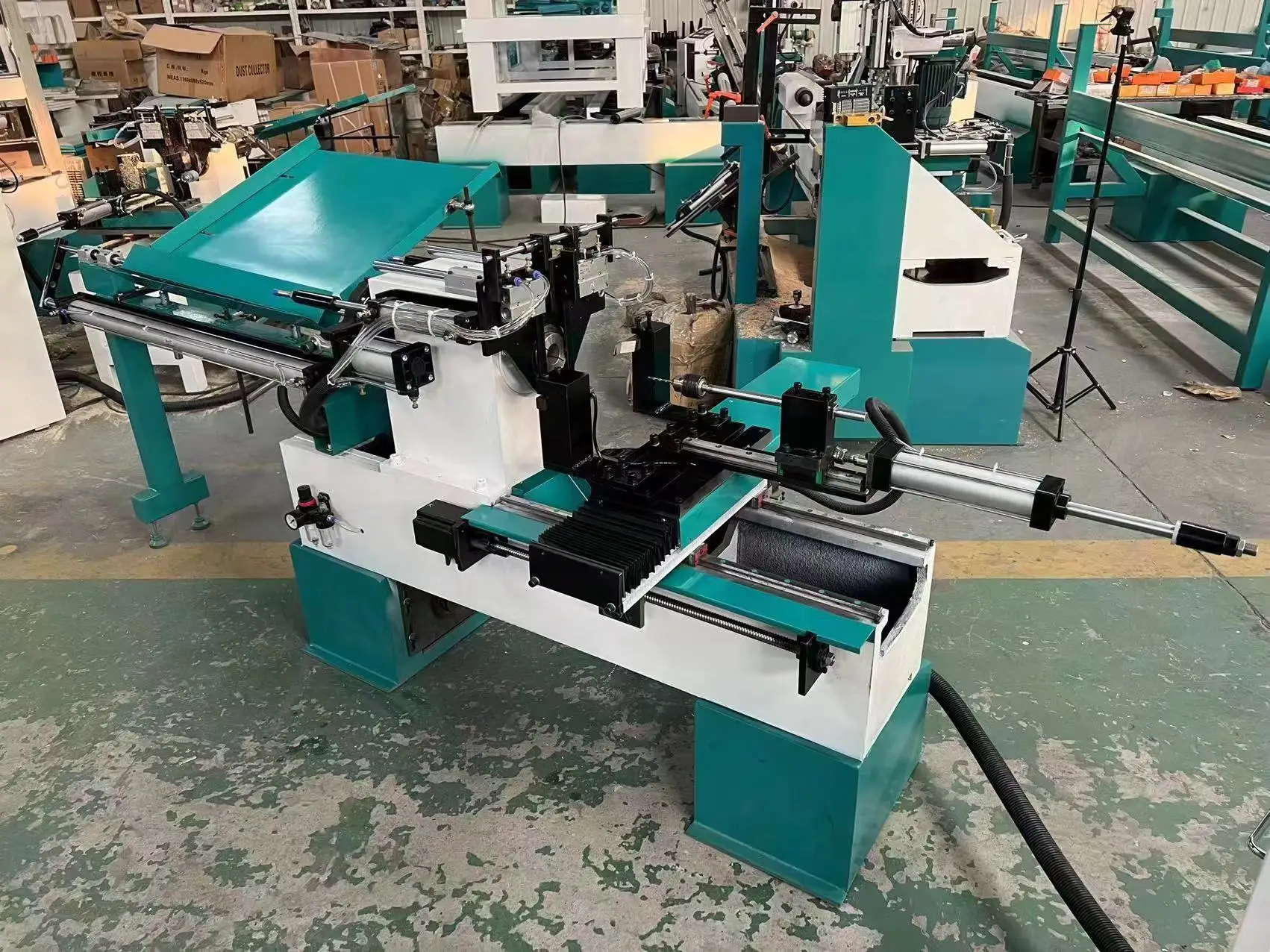

Automatic Feeding CNC Woodworking Lathe 70*150mm

- Section : Machinery

- Category : Lathe

- SKU : 1601024528880

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 01 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the working area of the Automatic Feeding CNC Woodworking Lathe?

The working area of the Automatic Feeding CNC Woodworking Lathe is 70mm by 150mm.

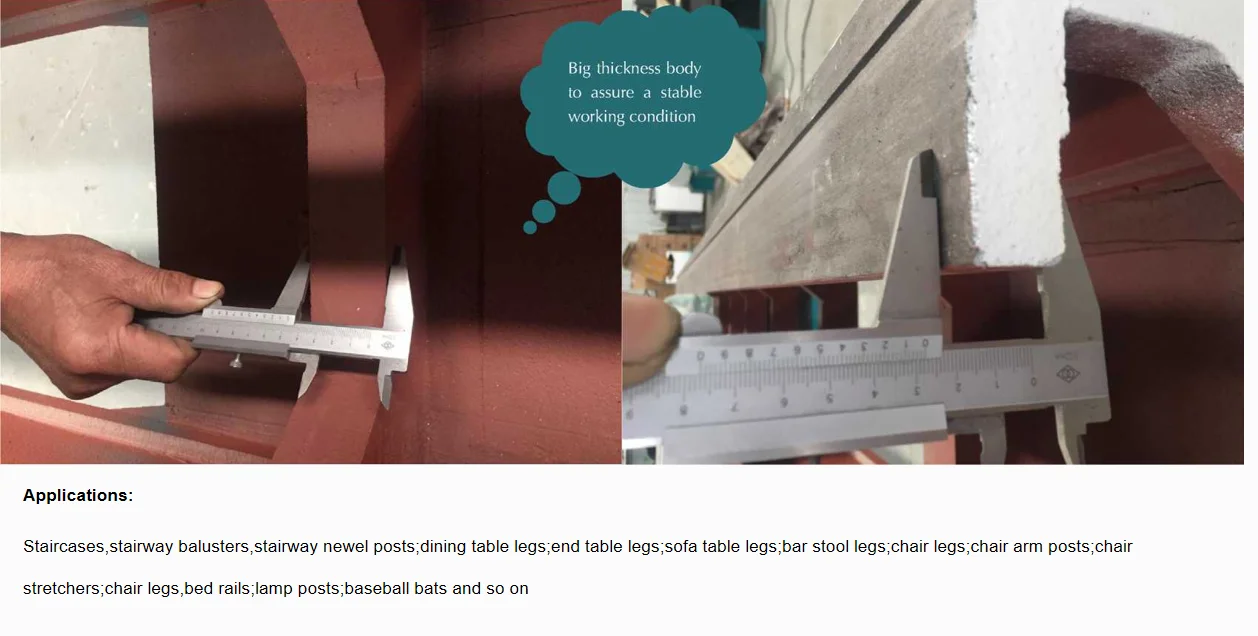

2. What materials is the body of the lathe made from?

The lathe features a cast iron body, which is designed to be durable and resistant to deformation over time.

3. What type of motor does the lathe use?

It uses a 4KW four-grade pure copper 3-phase asynchronous motor.

4. How many motors are included, and what are their specifications?

The lathe includes three motors: XY Axis 450B with 10Nm torque and Z axis 450C with 12Nm torque.

5. What type of transmission does the Y axis use?

The Y axis utilizes a helical rack gear transmission for smoother operation.

6. What is the advantage of the CNC special control system panel?

The CNC special control system panel, model 1000TC, provides precise control and programming capabilities for the lathe.

7. Does the lathe come with safety features?

Yes, it includes a filter/leakage protector for added safety during operation.

8. What kind of blades does the lathe use?

The lathe is equipped with Fuwang first grade best quality blades for optimal performance.

9. Can this lathe handle heavy-duty work?

Yes, the cast iron body and robust motor specifications allow the lathe to handle heavy-duty woodworking tasks.

10. Is there an option for an automatic loading/unloading system?

Yes, the lathe offers an optional auto loading and unloading system to enhance efficiency.

11. What are the benefits of using helical tooth rails?

Helical tooth rails improve efficiency and precision in movement, resulting in better machining results.

12. How long is the expected lifespan of this lathe?

With proper maintenance, the durable cast iron body can ensure the lathe remains stable and functional for over 10 years.

13. What is the overall weight of the lathe?

The specific weight of the lathe is not provided in the description, but the cast iron construction generally contributes to a heavier build.

14. Is training or support provided for the CNC control system?

Typically, manufacturers offer training resources and customer support for using the CNC control system effectively.

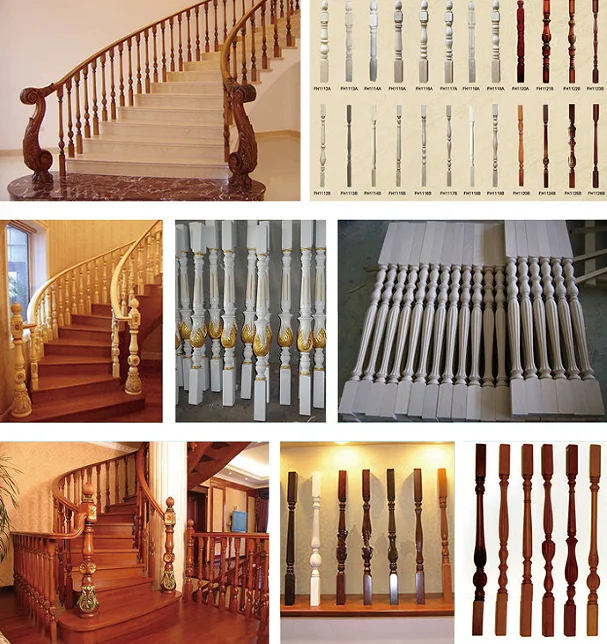

15. What type of projects is this lathe suitable for?

This lathe is ideal for precision woodworking projects, including turning, shaping, and other detailed woodwork.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading