B21, China Town Mall, Midrand

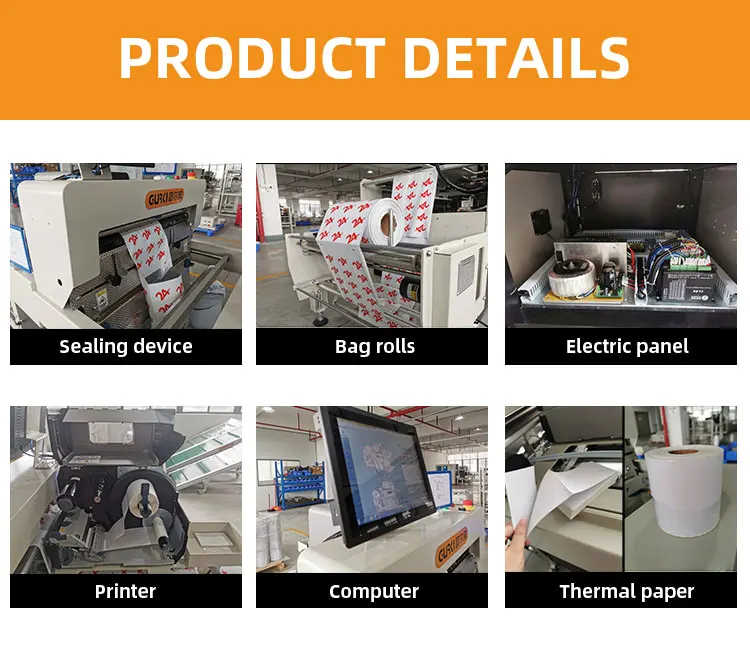

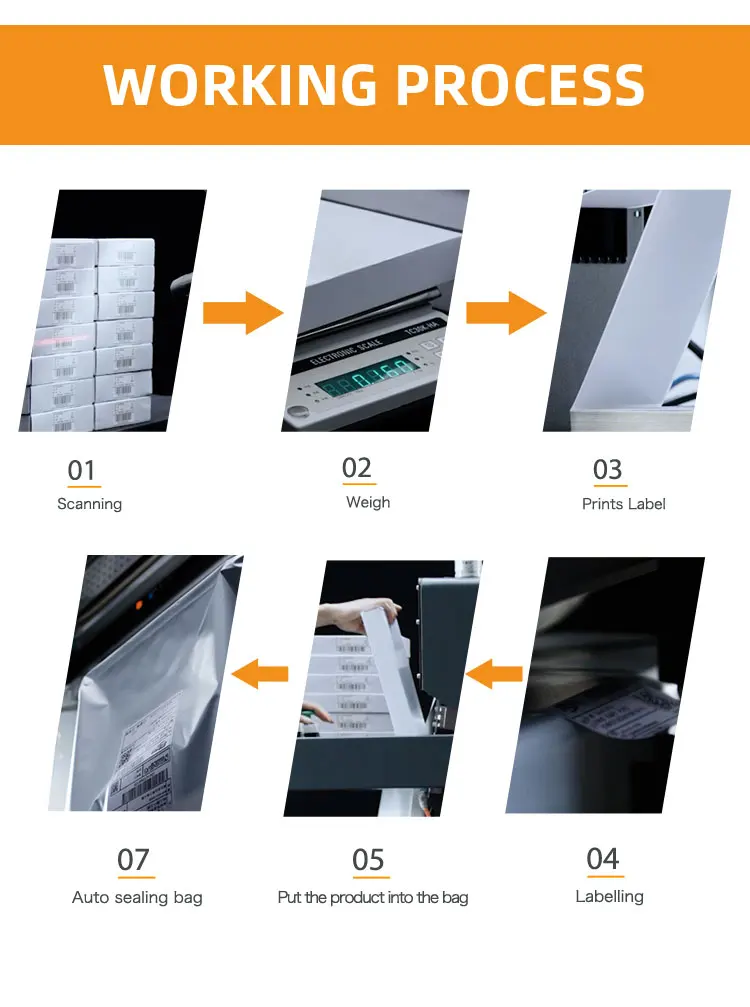

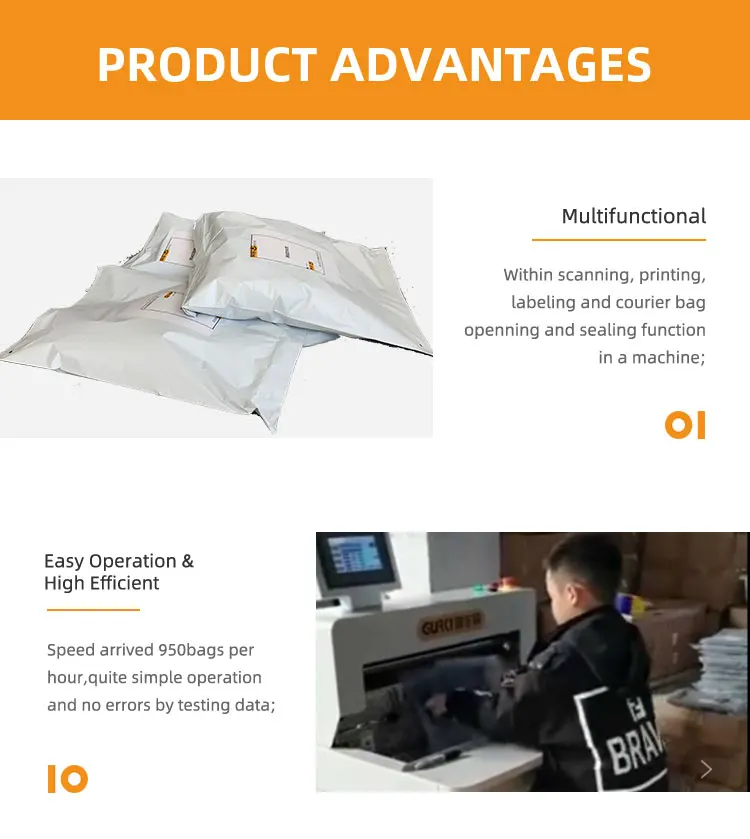

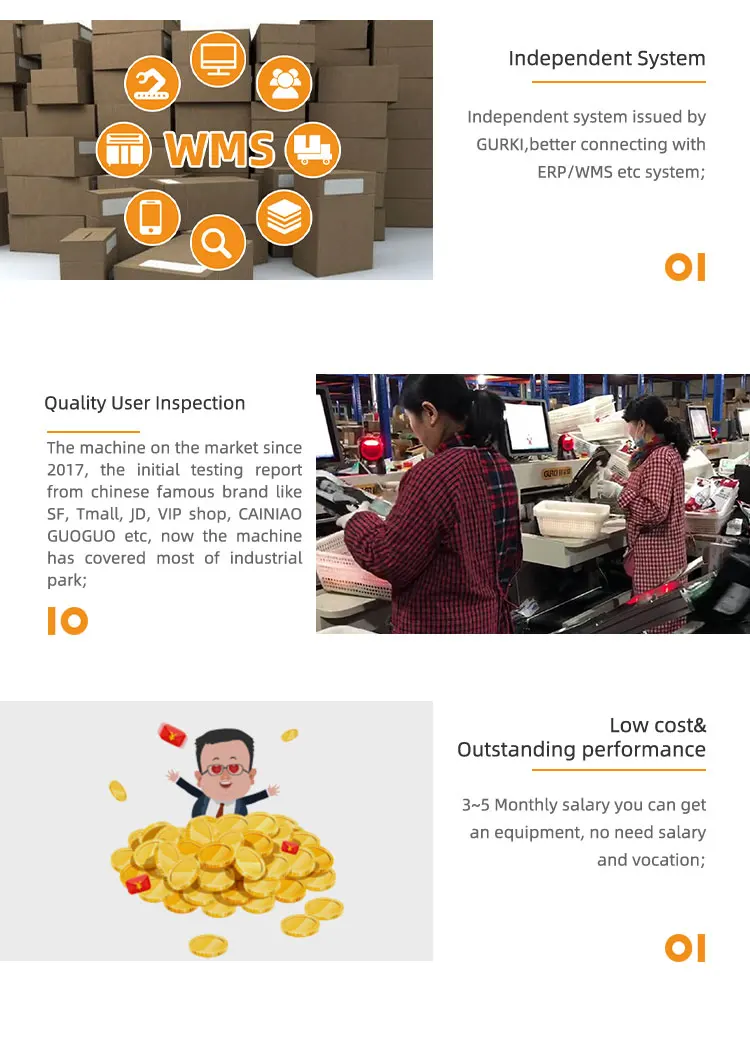

Auto Bagging Systems Autobagger Machine GS60D

- Section : Machinery

- Category : Packaging Line

- SKU : 1600241651400

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 23 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the maximum packaging speed of the GS60D?

The GS60D can package up to 1,200 bags per hour. Actual throughput depends on bag size, product characteristics and cycle settings.

2. What bag sizes and thicknesses does the GS60D support?

For PE rolling bags the machine supports thickness 0.04–0.08 mm, width 80–550 mm, and length 240–700 mm. Express sheet (small format) size: width 40–105 mm, length 10–180 mm.

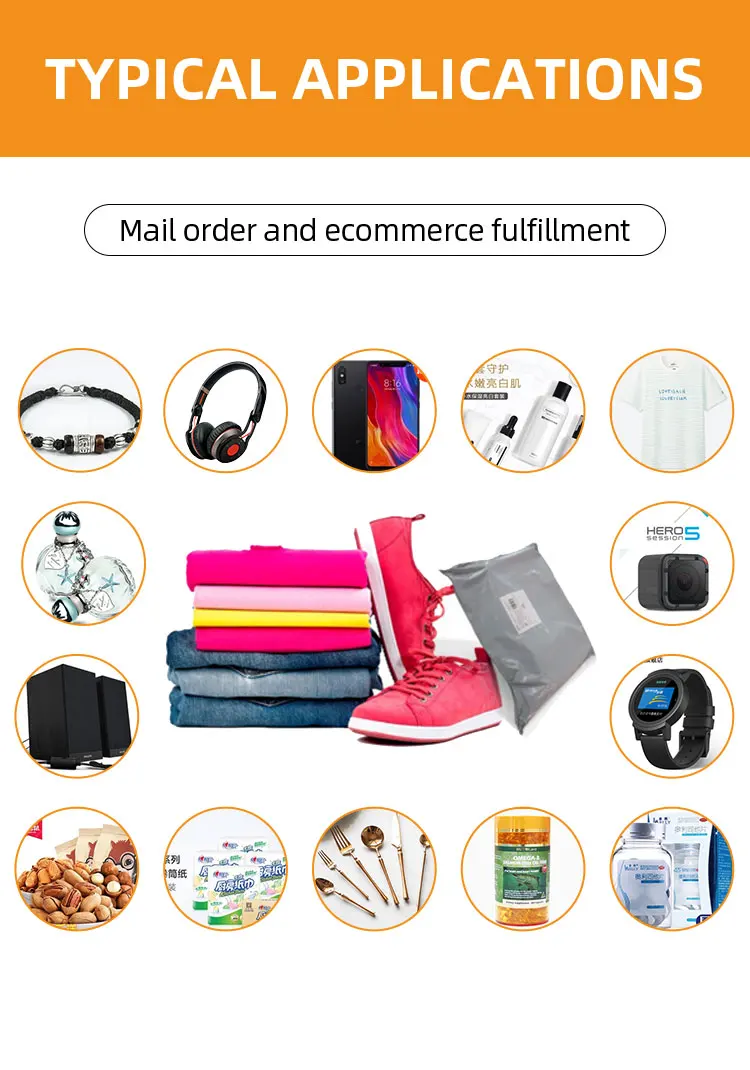

3. Which types of products can the GS60D bag?

The GS60D is designed for a wide range of products in food, beverage, chemical and textile industries. For wet, liquid, or highly abrasive products, please confirm compatibility with the supplier before purchase.

4. What are the electrical and pneumatic requirements?

Electrical: AC 220 V, 50/60 Hz, 1500 W. Pneumatic: 0.025 m³/min at approximately 5 kg/cm² (as specified). Verify site utilities prior to installation.

5. What user interface does the machine have?

The GS60D uses a man–machine interface with touch-screen operation; the specification lists a 15-inch LCD and supports mouse input and a virtual keyboard for easy operation.

6. What construction materials are used and is the machine durable?

The frame and structure are made from carbon steel for strength and long service life in industrial environments.

7. What are the machine dimensions and weight?

Machine dimensions: L 1680 mm × W 850 mm × H 1420 mm. Weight: approximately 250 kg.

8. How can the GS60D be integrated with my production line or control systems?

The machine supports external communication via Ethernet, USB and RS232, allowing integration with PLCs, printers, data collection systems and line control equipment. Specific integration may require configuration.

9. Are there built-in safety features?

Standard industrial safety features such as emergency stop and guarding are provided. For detailed safety certifications or additional guarding requirements, verify with the supplier to meet local regulations.

10. Does the GS60D offer printing, weighing or coding options?

The base specification does not list specific printers or weighers. Many systems can be fitted with optional coding/printing or checkweighing modules — contact the vendor for available options and integrations.

11. What routine maintenance is required?

Routine maintenance includes daily cleaning of product contact areas, regular inspection and replacement of wear parts (sealing jaws, belts, cutters), periodic lubrication of moving parts and software/parameter backups. Follow the supplier's maintenance schedule for best performance.

12. What spare parts and consumables should I keep on hand?

Common consumables include sealing elements/jaws, belts/chains, cutter blades, sensors and fuses. The supplier can recommend a spare-parts kit tailored to your production profile.

13. Is installation and operator training provided?

Installations typically require professional setup. Vendors usually offer commissioning and operator training packages — ask the seller about available on-site or remote training and documentation.

14. What warranty and after-sales support is available?

Warranty and support terms are not specified in this sheet. Contact the manufacturer or authorized distributor for warranty length, coverage and available service contracts or preventive maintenance plans.

15. How can I verify that the GS60D will meet my specific application needs?

Provide sample product, bag type and desired throughput to the supplier; they can run trials, confirm compatibility and recommend machine settings or optional accessories to ensure the GS60D meets your requirements.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading