B21, China Town Mall, Midrand

Asphalt Road Milling Construction Equipment LDS-500

- Section : Machinery

- Category : Construction Machinery

- SKU : 1600922866498

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 07 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the LDS-500 designed for?

The LDS-500 is a concrete scarifier and asphalt milling machine designed for surface preparation tasks such as removing asphalt or concrete toppings, removing line paint, cleaning road surfaces, and profiling or texturing concrete and asphalt.

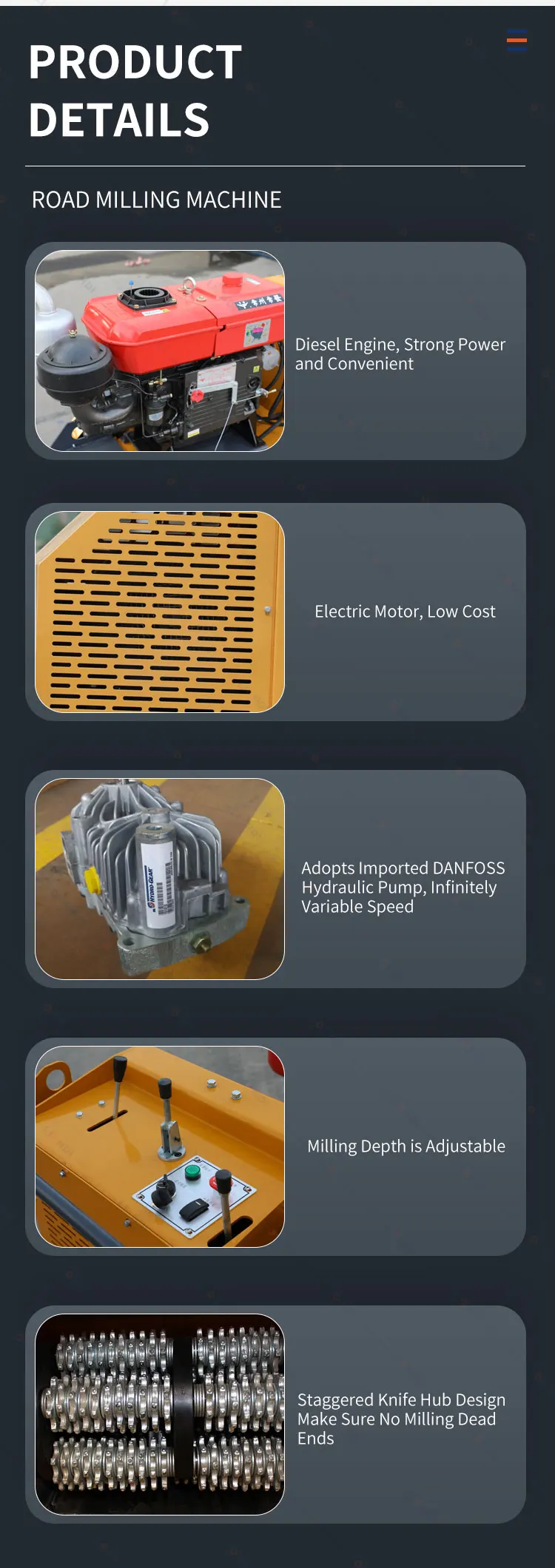

2. What power options are available for the LDS-500?

The LDS-500 is offered in multiple power configurations. Common options include a gasoline engine (Honda), an electric motor, and a diesel variant (listed as Diesel CF25 17 kW). Confirm the exact power configuration when ordering.

3. What is the maximum scarifying/milling depth?

Scarifying depth is adjustable from 0 to 10 mm, allowing fine control for light surface removal up to deeper milling within that range.

4. How fast does the unit walk and how productive is it?

Walking speed is adjustable from 0–30 m/min (infinitely variable via hydraulic transmission). Typical working efficiency is rated at approximately 230 m²/hour, dependent on material and operating conditions.

5. What type of transmission and controls does the LDS-500 use?

The machine uses a hydraulic stepless (infinitely variable) transmission for walking and torque management. Depth is controlled via electric lifting controls for precise adjustment.

6. Tell me about the cutting drum and cutters.

The LDS-500 uses a high-speed rotating multi-point cutting drum with a standard knife hub width of 500 mm and 270 cutting blades. The drum is heat-treated for durability and is designed for fast replacement.

7. How long does it take to change the scarifying drum?

The scarifying drum is engineered for quick replacement and can be changed in approximately five minutes, minimizing downtime on the jobsite.

8. What are the machine dimensions and weight for transport planning?

Overall size is 1600 × 830 × 950 mm and the machine weight is approximately 380 kg. It can be transported on a light truck or trailer; use appropriate lifting equipment and securement for safe transport.

9. What routine maintenance is recommended?

Daily: inspect cutters, remove debris, check hydraulic lines and fluid levels, and verify controls. Periodically: replace worn blades, service the engine/motor per manufacturer guidelines, and check drum bearings and fasteners. Follow supplier maintenance schedule for hydraulic fluid and engine service intervals.

10. What safety equipment and precautions should operators use?

Operators should wear hearing protection, eye protection, gloves, protective footwear, and dust/mist masks or a respirator when cutting dusty materials. Ensure good ventilation, keep bystanders clear, and follow lockout/tagout procedures for maintenance. Read the operator manual for full safety instructions.

11. Can the LDS-500 be used on both asphalt and concrete?

Yes. The LDS-500 is suitable for both asphalt and concrete surface preparation and milling tasks within its depth and cutter configuration limits.

12. How long do the cutting blades last and are replacements available?

Blade life depends on material, application, and operator technique. Harder or abrading surfaces and improper use shorten life. Replacement blades and cutter kits are available from the supplier — keep spare cutters on hand for continuous operation.

13. Does the LDS-500 produce a lot of dust and noise?

Scarifying and milling generate dust and noise. Use appropriate dust control measures (water suppression or vacuums where applicable) and PPE for operators. Noise levels vary by engine type and cutting conditions; refer to the supplier for measured sound levels of your chosen power configuration.

14. What attachments or accessories are commonly available?

Common accessories include spare cutter sets, replacement drums, dust control attachments or collection systems, transport brackets, and different cutter geometries for specific materials. Contact the dealer for compatible accessories and retrofit options.

15. Is there a warranty and local service support?

Warranty terms and local service availability vary by seller and region. Ask your supplier or dealer for specific warranty coverage, authorized service centers, and spare parts availability before purchase.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading