B21, China Town Mall, Midrand

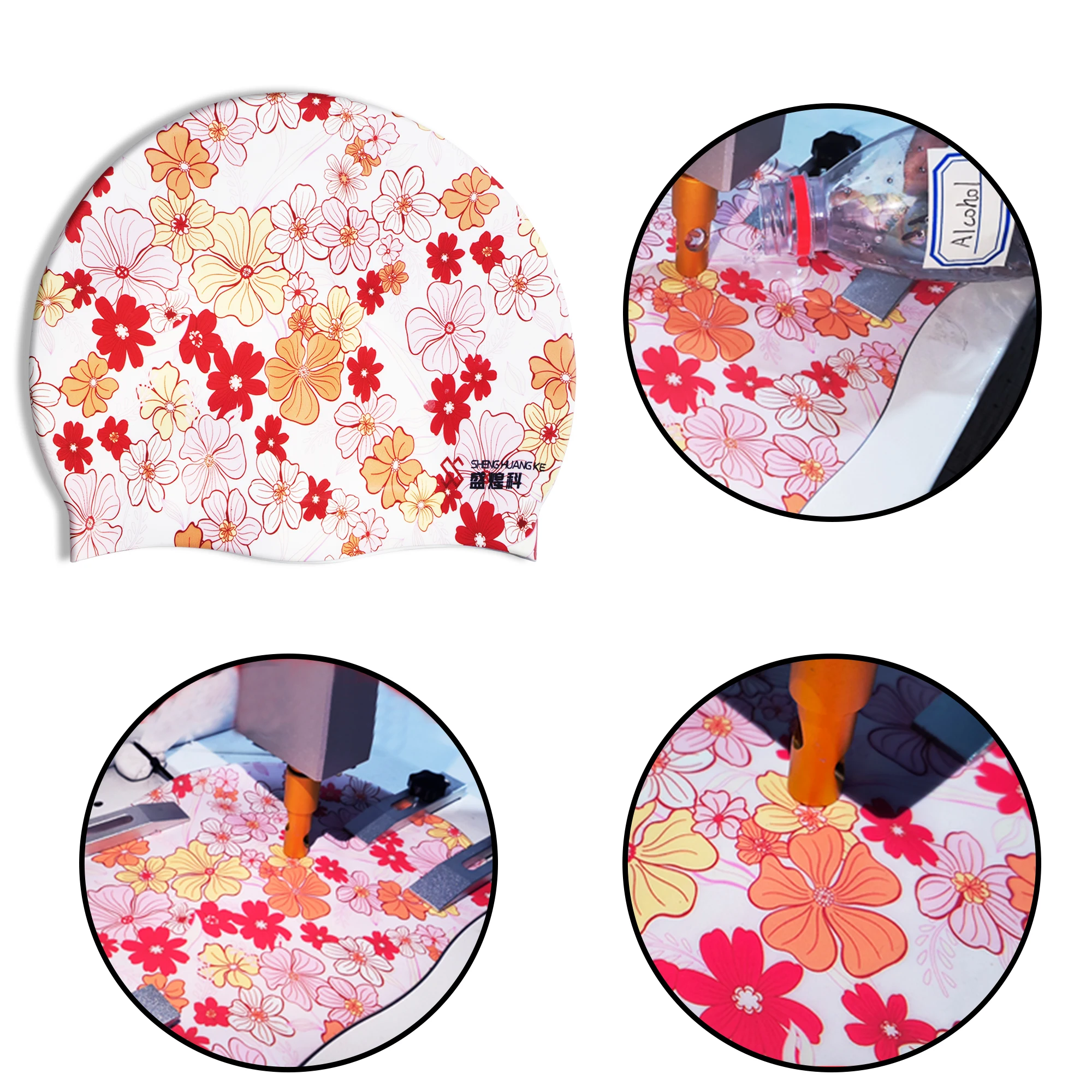

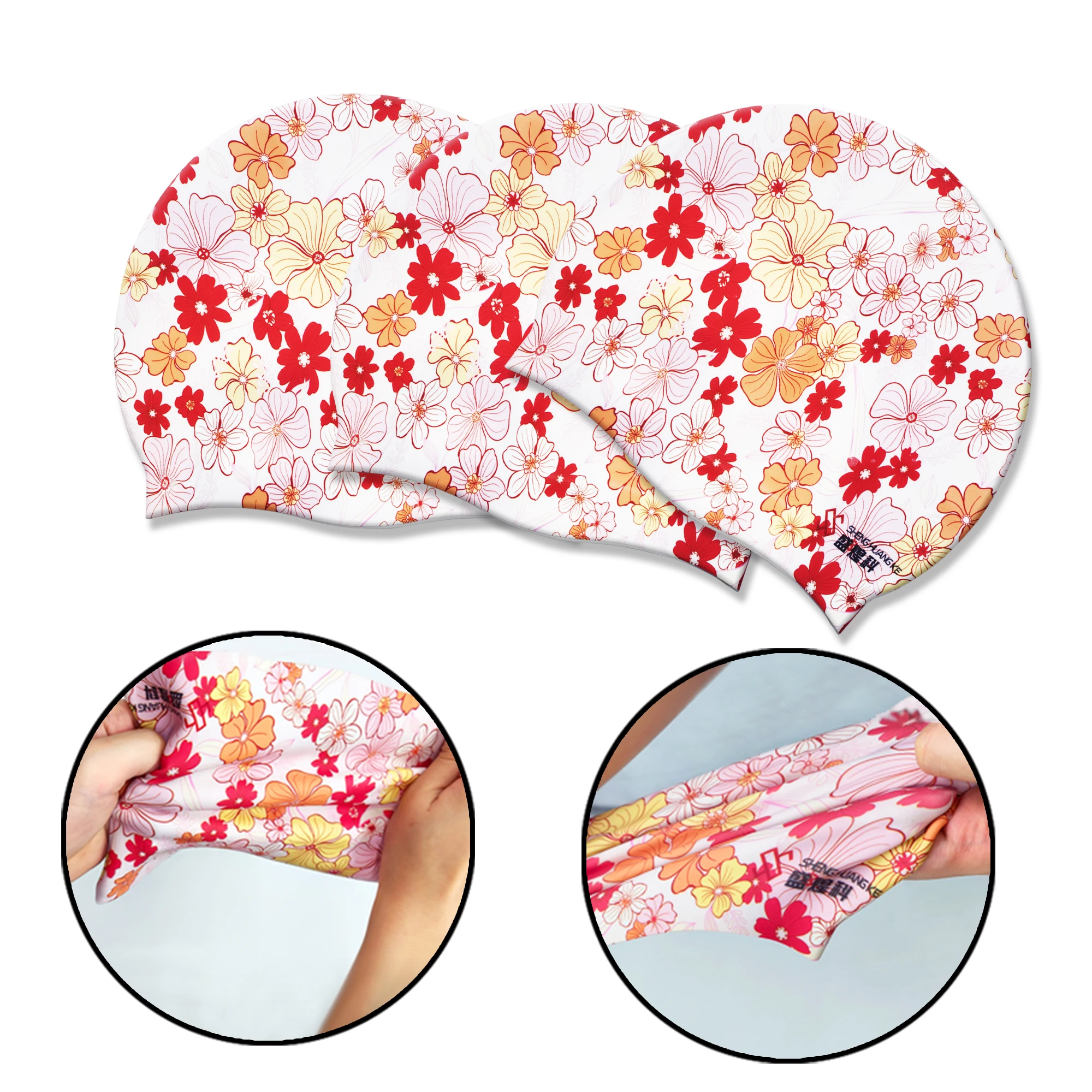

anti collision rubber swimming cap flatbed a3 uv printer

- Section : Consumer Electronics

- Category : Digital Printers

- SKU : 11000008057795

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What types of materials can the anti-collision rubber swimming cap flatbed A3 UV printer print on?

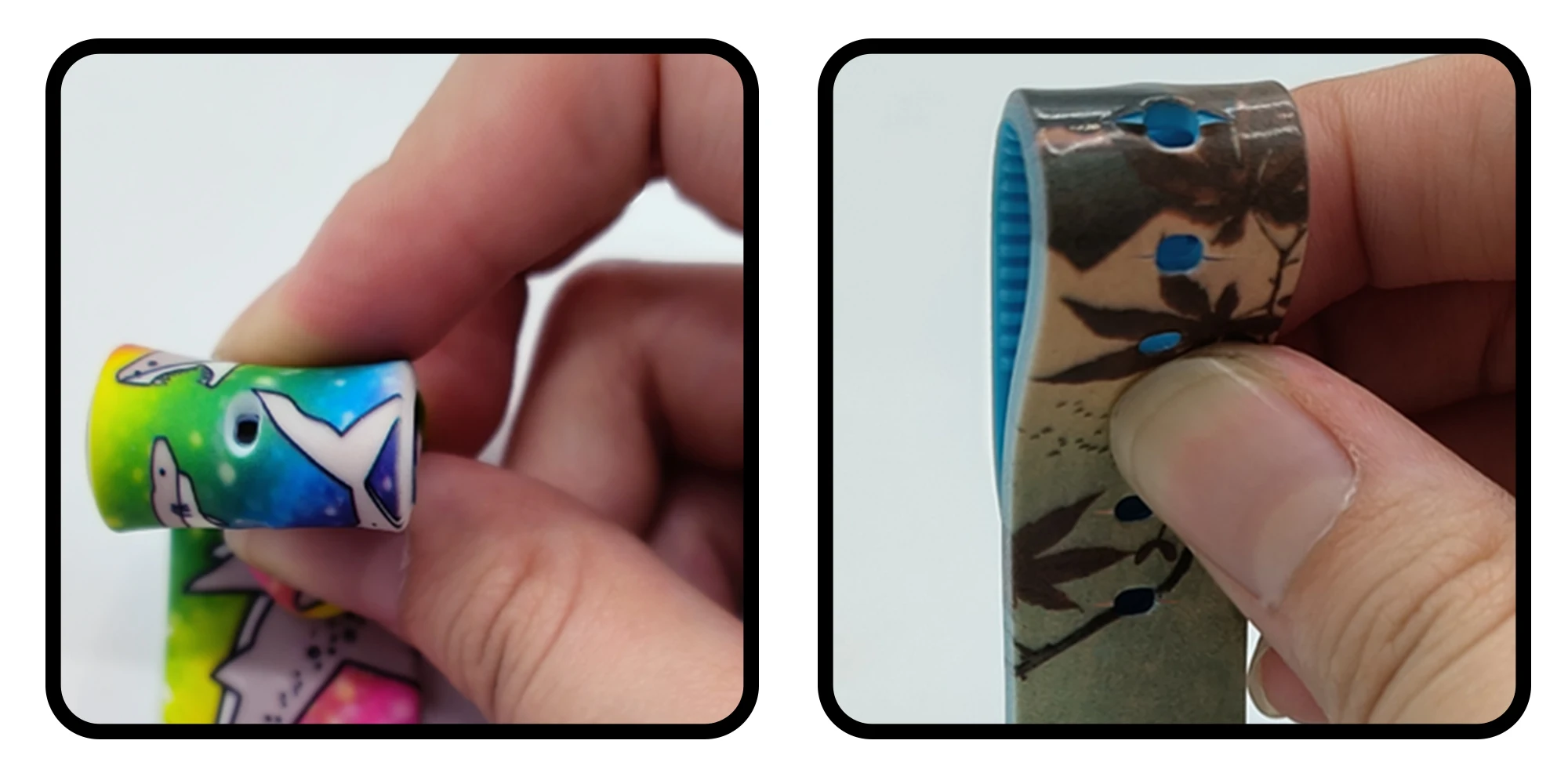

The printer can print on a variety of materials including hard surfaces like acrylic, wooden panels, metal sheets, marble, and bottles, as well as soft materials such as silicone, leather, TPE flexible film, PVC flexible film, and rubber.

2. What is the maximum print size of the printer?

The maximum print size of the anti-collision rubber swimming cap flatbed A3 UV printer is 600mm x 1800mm.

3. What is the print speed of the printer?

The printer has a print speed of 70 pieces per hour, and it can print 35 swim caps in approximately 30 minutes.

4. What are the advantages of using this printer for swim cap printing?

The printer offers contrast screen printing, allowing for single color prints and full-color prints in one operation, reducing the traditional coloring and spraying processes.

5. What types of inks does the printer support?

The printer supports both soft ink and hard ink, allowing for a wide range of applications and vibrant color results.

6. What is the weight of the printer?

The anti-collision rubber swimming cap flatbed A3 UV printer weighs 300 kg.

7. Can I get a sample printing support?

Yes, sample printing support is available; however, shipping costs are not included.

8. What kind of test items can be conducted with this printer?

You can conduct tests such as alcohol corrosion tests and friction resistance tests to ensure the durability of printed items.

9. What is the curing system used in the printer?

The printer uses an LED UV lamp curing system or a UV mercury lamp for curing the inks.

10. What is the print accuracy of the printer?

The print accuracy of the printer is 2880 DPI x 1440 DPI.

11. What types of documents can be received by the printer?

The printer can receive documents in formats such as TIFF, BMP, EPS, JPEG, and PDF.

12. What kind of software is compatible with the printer?

The printer is compatible with Windows 7 64-bit operating system for printing software.

13. What is the power requirement for the printer?

The printer operates on a power supply of 110-220V at 50-60Hz and consumes 75W.

14. Is the printer suitable for printing on silicone products?

Yes, the printer is specifically designed to print on silicone products, providing excellent adhesion and vibrant colors.

15. What kind of protection does the printhead have?

The printer features smart touch protection for the printhead to ensure longevity and consistent performance.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading