B21, China Town Mall, Midrand

AMJ L800 Hologram Trading Game Card UV Printer

- Section : Machinery

- Category : Digital Printers

- SKU : 62187859744

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 20 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What media and substrates can the AMJ L800 Hologram Trading Game Card UV Printer print on?

The AMJ L800 can print directly on a wide range of materials including hologram and holo-foil cards, transparent materials, white and black cards, and most card-stock and paper substrates suitable for UV inks.

2. What is the maximum printable size and thickness?

Maximum printable area is A4 (210 × 297 mm). The maximum object height is 6 cm, and the printer supports non-destructive weights up to 15 kg.

3. What print quality and speed can I expect?

Maximum printing precision is up to 2880 × 1440 dpi. Typical A4 printing at 1440 dpi takes about 3 minutes per sheet (bidirectional printing), depending on image complexity and settings.

4. Which colors and ink capabilities does the L800 offer?

The printer uses a six-color configuration (CMYK + two white channels), allowing single-pass white printing for vivid results on dark or transparent substrates. Ink tank capacity is 120 ml per color.

5. Is this a true UV printer and what type of ink does it use?

Yes. The AMJ L800 is a UV printer designed for UV-curable inks (used for immediate curing of prints). For safe and optimal operation use the inks specified by the manufacturer or supplier.

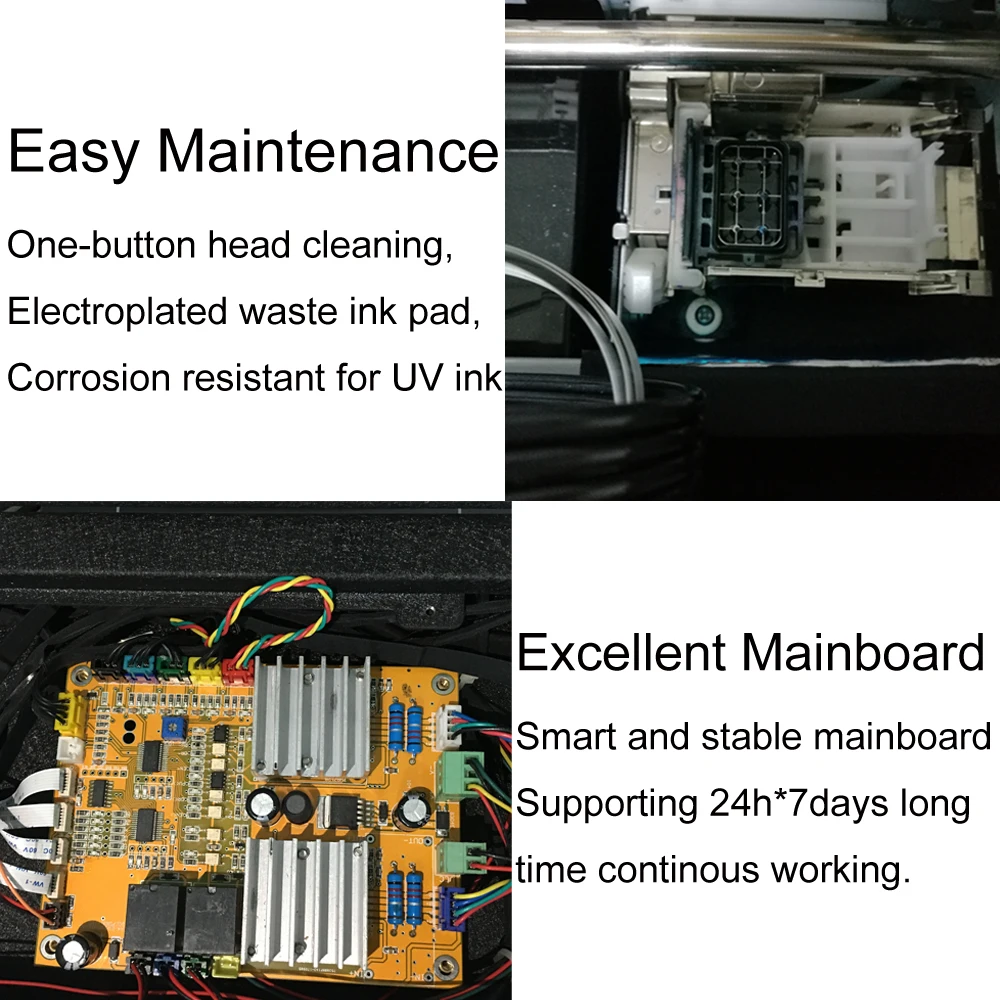

6. How does the printer handle maintenance and printhead care?

The L800 includes automatic height adjustment, automatic head cleaning, and automatic nozzle protection/touch detection to reduce manual maintenance. Regular scheduled checks and occasional manual cleaning as recommended by the vendor will extend printhead life.

7. What cooling and environmental requirements does it have?

The unit features an integrated water cooling system to maintain optimal operating temperatures during long runs. Recommended working environment is 10–35°C and 20–80% relative humidity.

8. What are the physical size, weight and power specifications?

Manufacturer specs list the printer dimensions as approximately 560 × 520 × 280 mm (some product pages note ~600 × 450 × 300 mm). Net weight is around 25–27 kg and gross weight ~30 kg. Power requirements are 110–220 V, 50–60 Hz, 75 W.

9. How does continuous loading work and is it suitable for batch jobs?

Continuous loading enables uninterrupted printing for larger projects and batch runs, improving productivity when producing multiple cards or sheets. Exact workflow depends on the media handling setup and job software.

10. What connectivity and operating systems are supported?

The AMJ L800 supports USB 2.0 and IEEE 1394 interfaces and is designed to run on Windows-based systems. Confirm driver and RIP software compatibility with your specific Windows version.

11. Can the printer produce embossed or holographic effects directly?

Yes — the printer can produce plain, embossed-looking, and holographic effects when printing onto holographic or special effect foils and substrates. Actual tactile embossing depends on the substrate; for true tactile embossing a separate finishing process may still be required.

12. What safety precautions should I take when operating a UV printer?

Use appropriate PPE (gloves and eye protection) when handling inks, ensure good room ventilation, avoid direct exposure to UV curing lamps, and follow manufacturer instructions for ink handling and waste disposal.

13. What consumables and spare parts should I budget for?

Plan for replacement UV inks (120 ml tanks), printhead maintenance supplies, cleaning fluids, and potential spare parts such as dampers or caps. Lifespan varies with usage—ask the vendor for recommended stock levels based on your print volumes.

14. Is installation, training, or warranty included?

Specifics about installation, on-site setup, training, and warranty vary by supplier. Contact the seller or distributor for details on included services, warranty coverage, and optional support packages.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading