B21, China Town Mall, Midrand

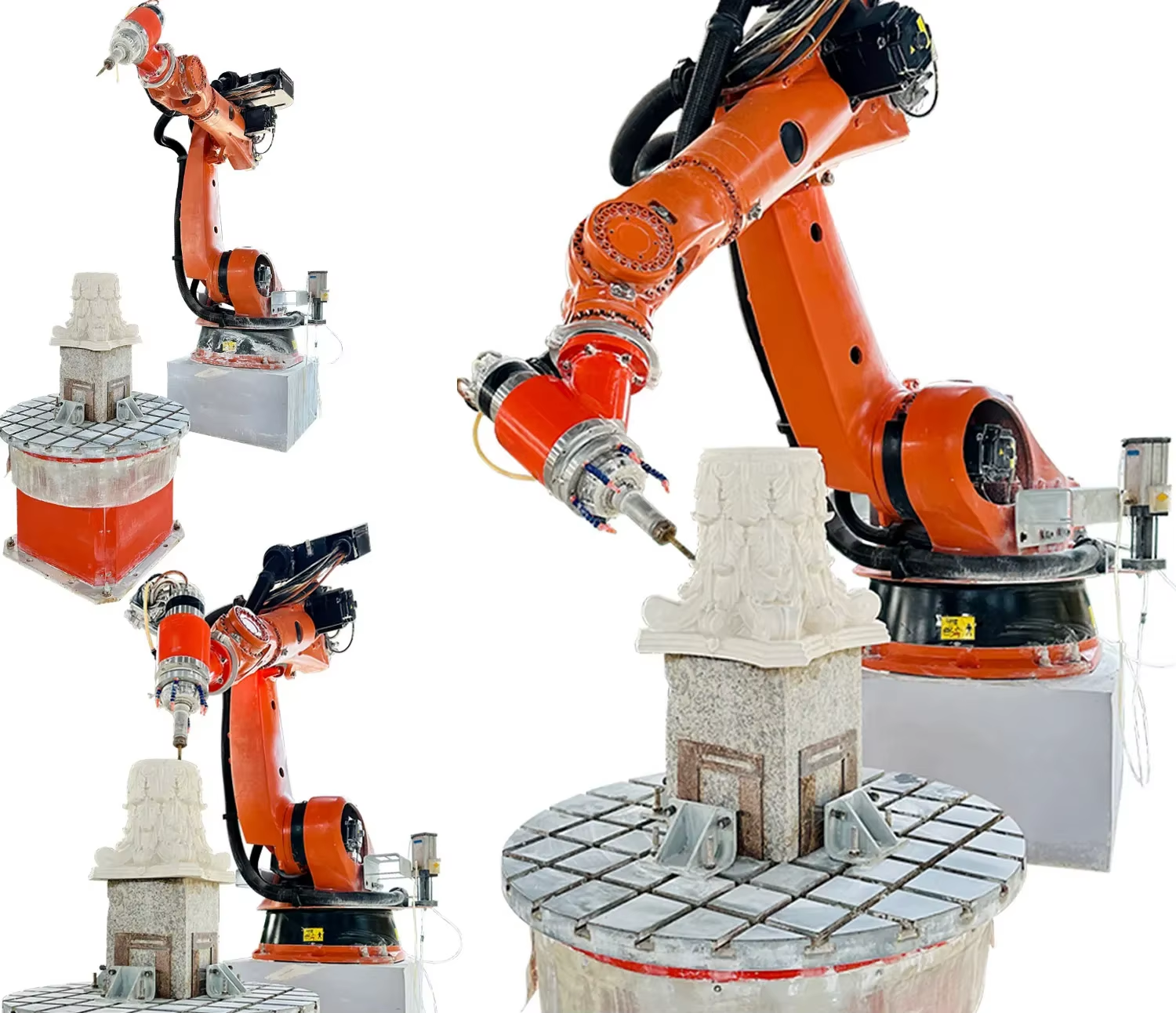

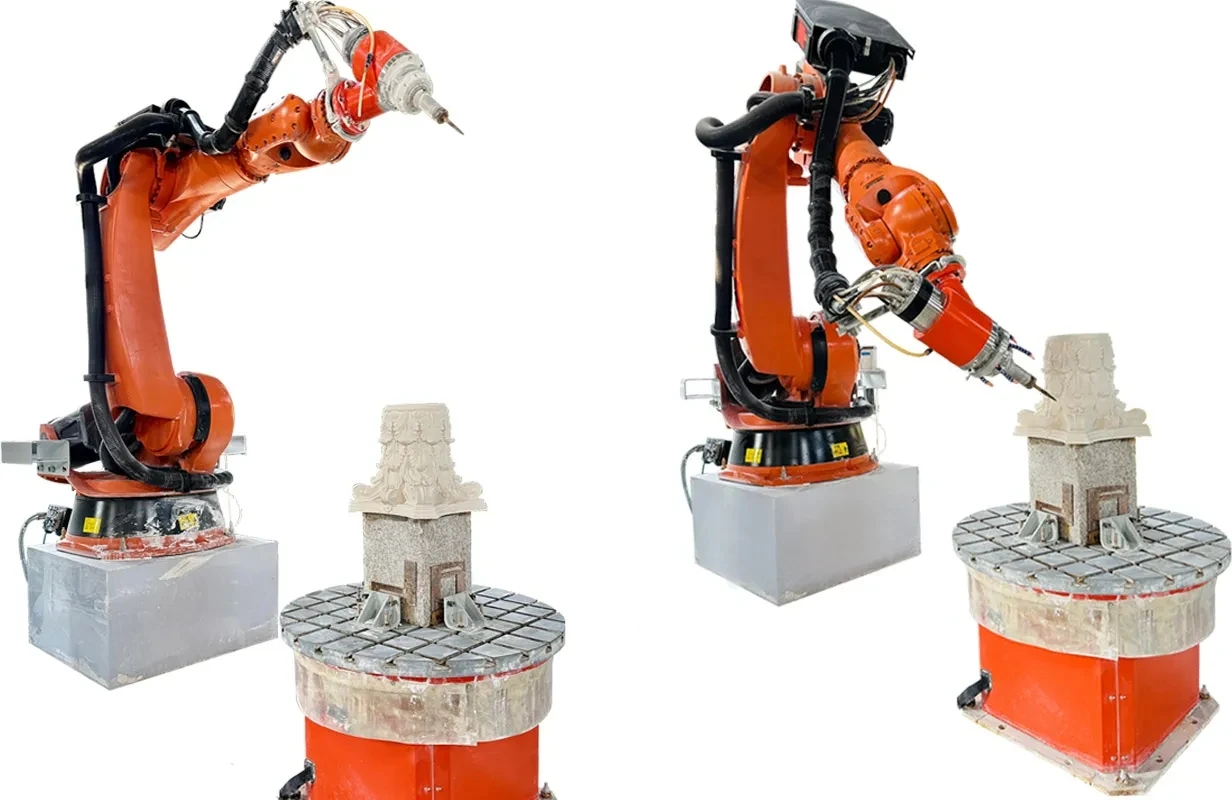

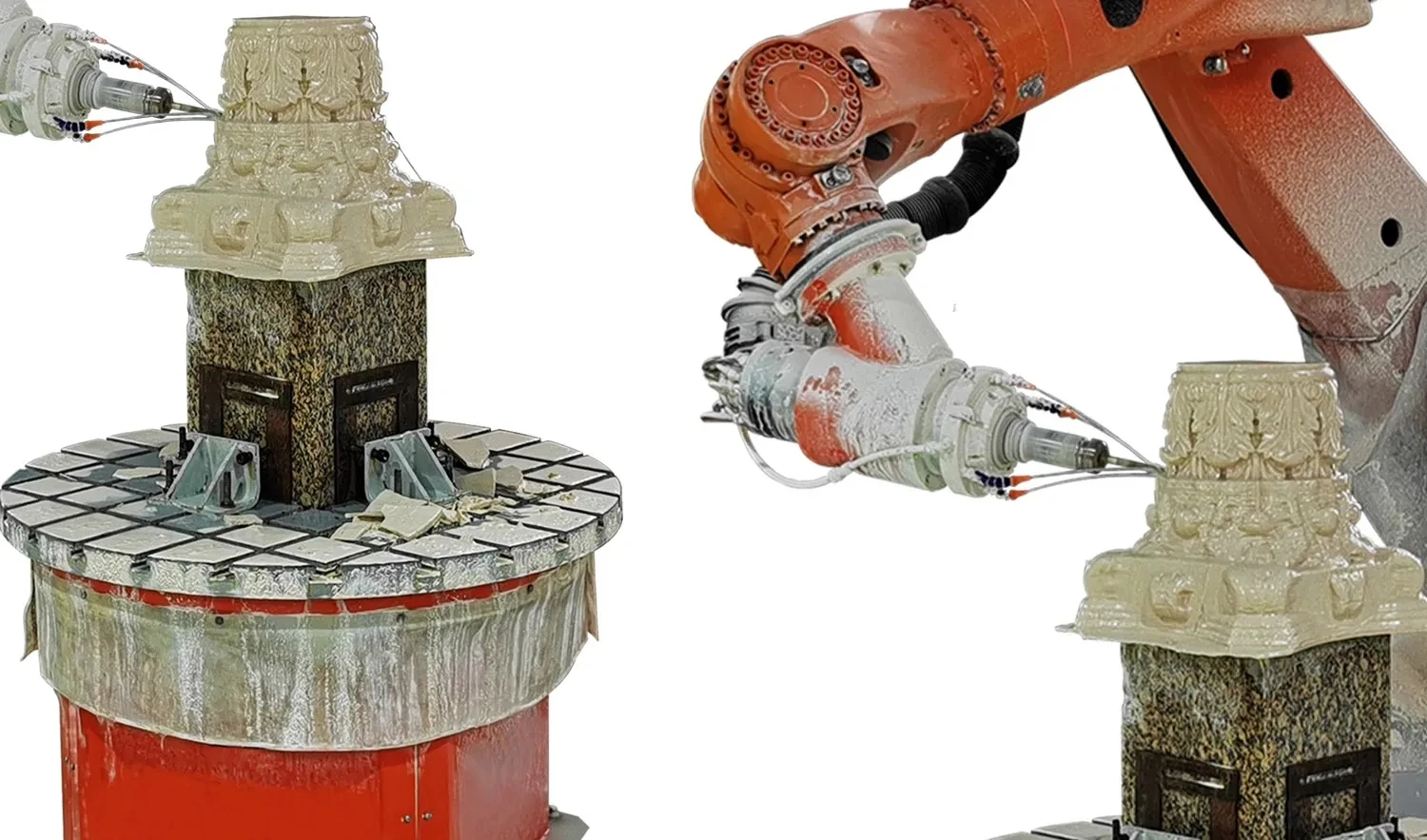

7 axis robot arm cnc engrave machine robot stone carving and Sculptures Machine for marble granite

- Section : Machinery

- Category : Stone Machinery

- SKU : 1600818794553

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 01 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What materials can the 7 Axis Robot Arm CNC engrave machine work with?

The machine is designed primarily for stone materials such as marble and granite, making it suitable for various stone carving applications.

2. How precise is the engraving process with the robot arm?

The robot arm features a repeat positioning accuracy of less than +/- 0.06 mm, ensuring high precision in the engraving process.

3. What is the maximum load capacity of the robot arm?

The 7 Axis Robot Arm has an actual load capacity of 210 kg, allowing it to handle substantial stone pieces.

4. Is the robot arm suitable for outdoor use?

Yes, the robot arm is designed to operate in harsh environments and is waterproof and dustproof, making it suitable for outdoor use.

5. What software does the machine use for programming?

The robot uses the offline programming software Sprut CAM, which allows for complex 3D modeling and sculpture processing.

6. Can the configuration of the robot arm be changed?

Yes, the configuration of the robot arm can be changed at will to accommodate various processing needs.

7. What is the maximum spindle speed of the machine?

The maximum rotating speed of the spindle is 18,500 rpm/min, enabling efficient engraving and carving operations.

8. How long is the service life of the robot arm?

The robot arm has a service life of up to 15 years, with an average time between accidents of approximately 70,000 hours.

9. What types of tools can be used with this machine?

The machine supports a variety of tools, including saws for roughing, milling cutters, end mills, and polishing wheels.

10. What is the maximum processable size for engraving?

The maximum processable size for engraving with this machine is 1000 x 2500 mm.

11. How does the robot improve productivity compared to manual routing?

The robot can produce more parts per hour than manual routing or CNC machine routing, thereby significantly increasing productivity, repeatability, and quality.

12. What applications are best suited for this robot arm?

The robot arm is ideal for creating stone sculptures, such as Buddha statues, church sculptures, balustrades, tombstones, and other stone crafts.

13. What is the working circumference of the robot arm?

The working circumference of the 7 Axis Robot Arm is 3100 mm.

14. Is training required to operate the robot arm?

While the robot is designed to be easy to operate, some training in using the Sprut CAM software and the machine's features is recommended for optimal results.

15. What is the motion range and speed for each axis?

The motion ranges and speeds for the axes vary; for example, Axis 1 has a range of +/-185° with a speed of 86°/s, while Axis 7 allows for endless rotation at 84°/s.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading