B21, China Town Mall, Midrand

6090 Die Cut Machine - ZUNSUN

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1600885197077

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 24 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the working area of the 6090 Die Cut Machine?

X-axis: 610 mm for non-contour cutting and 600 mm for contour (edge) cutting. Y-axis: sheet handling up to 910 mm; roll media supported as whole rolls. Maximum applicable material width: 779 mm.

2. Which materials can the 6090 cut and what thicknesses are supported?

Designed for flexible media such as PET/DTF films (including UV DTF), reflective film, PPF/paint protection film, vinyl, PVC, adhesive films, magnetic sticker, multilayer film, flexible circuit film and paper (up to ~500 gsm). Recommended standard maximum thickness is ≤1.5 mm; some flexible media may be processed up to ~3 mm in certain settings—test and confirm with the manufacturer before regular use.

3. What is the maximum cutting force and speed?

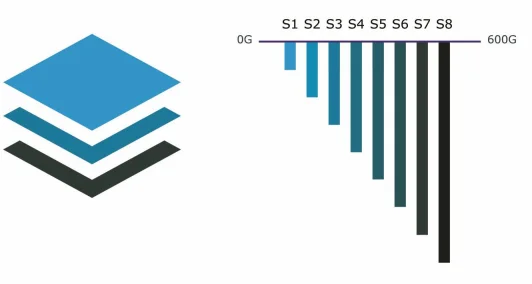

Maximum knife pressure is 600 g (5.8 N) delivered in 8 separate pressure groups. Cutting speed is up to 600 mm/s. Knife pressure is adjustable with 1-gram resolution.

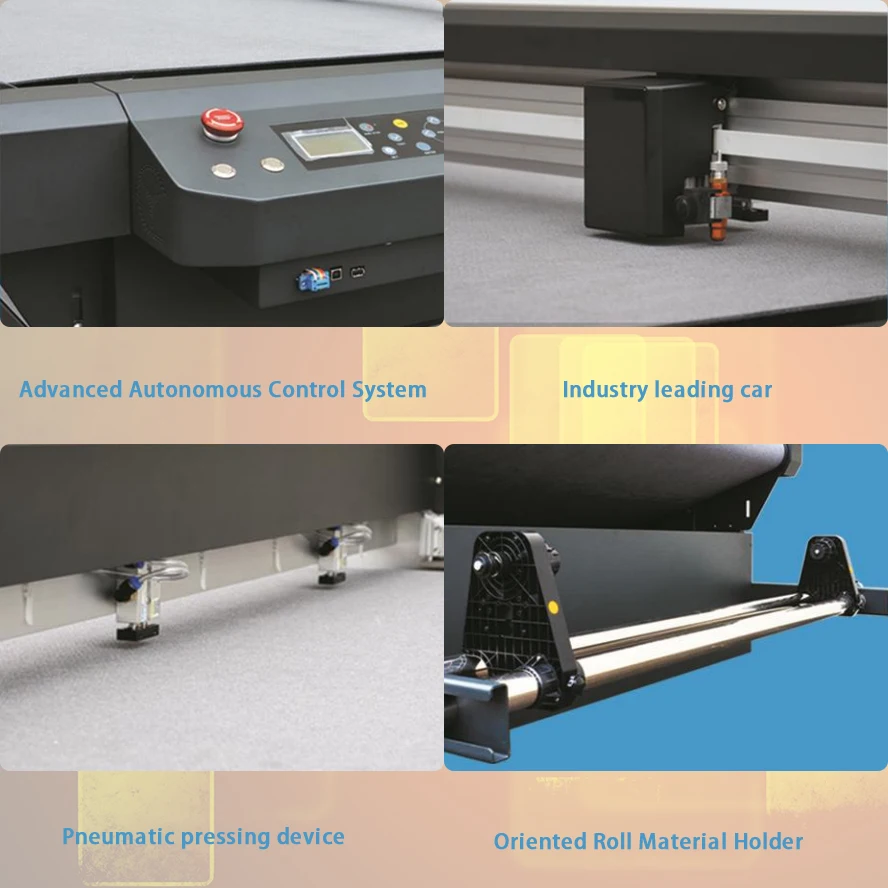

4. How is media held and fed during cutting?

Media is fixed using a vacuum adsorption (vacuum table) platform. Feeding methods include a conveyor (automatic transfer device) for sheets and a roll-media bracket for roll-to-roll processing for fast, continuous work.

5. What file formats, software and operating systems are supported?

Supports common cutting file formats such as HP-GL/PLT. Standard software/drivers include Windows driver, SignWorkPro and CADtoPlotPro. Compatible with Windows 10/8/7/XP.

6. What connectivity and peripheral features does the machine have?

Data interfaces: USB and RS-232. Built-in high-definition CCD camera for marker/outlines extraction and automatic positioning. Barcode recognition is available as an optional feature for offline/job-cycle cutting.

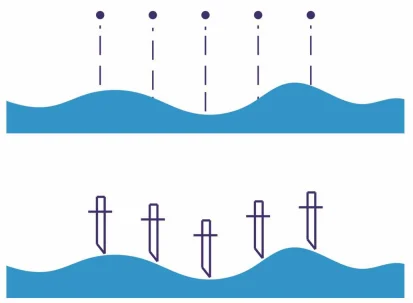

7. Can the machine do half-cut and full-cut reliably on uneven materials?

Yes. The machine includes an intelligent countertop compensation system that uses precision gratings to automatically compensate knife pressure during cutting, enabling accurate half-cuts and full-cuts on slightly uneven surfaces without damaging the pad.

8. What are the physical dimensions, power requirements and weight for the 6090?

Typical installation area: 1200 × 1080 × 980 mm. Package size: 1600 × 1200 × 1180 mm. Gross/Net weight: approx. 280/220 kg. Input voltage: AC 220 V, 50–60 Hz. Typical power consumption for the 6090 model: ~2.2 kW.

9. How many pressure zones does the machine support and how are they used?

The system subdivides cutting into 8 groups of knife pressure which are output separately and can be assigned to different paths/colors in your cutting program—useful for multi-layer or mixed-material jobs and for optimising cuts without manual pressure switching.

10. What types and sizes of blades/tools are compatible?

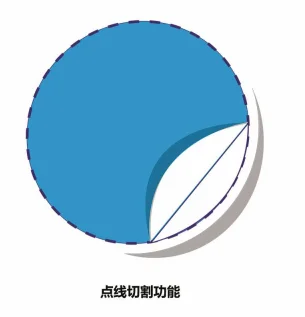

Standard tool holder accepts knives with a 2.0 mm shank. Common blade tip angles supported include 30°, 45° and 60°. The machine supports a variety of carving and cutting tools including point/line cutting blades—select blade type by material and required cut (kiss cut vs full cut).

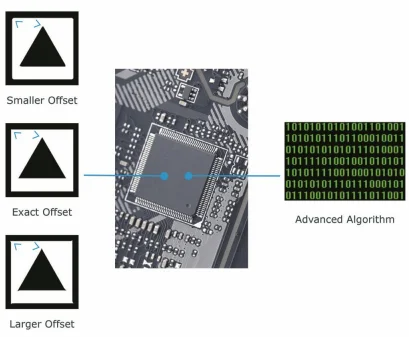

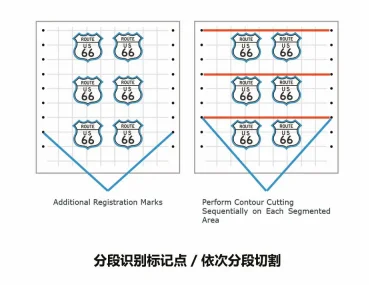

11. What does the CCD camera do and how accurate is marker recognition?

The CCD camera quickly extracts graphic outlines, automatically recognizes boundaries and marker points, and works with software to generate cut paths one-click. It supports segment recognition, sequential/sectional cutting and high-precision contour cutting to compensate for print distortion and improve nesting efficiency.

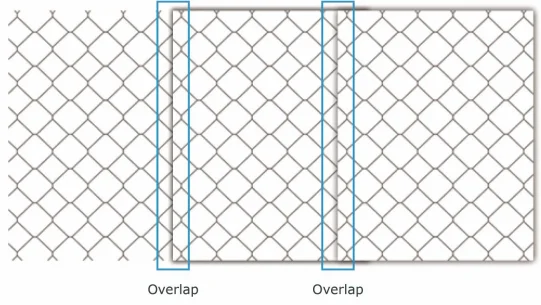

12. Does the machine support large-format splitting and splicing?

Yes. Included software features intelligent split/overlap stitching for typesetting and splicing large-format signage, which simplifies cutting and splicing of oversized jobs and improves alignment for multi-panel outputs.

13. What routine maintenance is required?

Recommended maintenance: keep the vacuum table clean and free of debris, inspect/replace blades when they become dull, check and replace felt pads as needed, ensure carriage rails and guide components are clean and lubricated per manufacturer instructions, and perform regular calibration/tool-nose compensation checks. Use manufacturer-approved parts and consult ZUNSUN or your reseller for spares.

14. What support, training and warranty options are available?

Warranty, training and support packages vary by seller and region. The machine provides one-click driver installation and is compatible with popular industry software; many resellers offer on-site installation, training and spare parts. Contact ZUNSUN or your authorized dealer for details on warranty length, service plans and available training.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading