B21, China Town Mall, Midrand

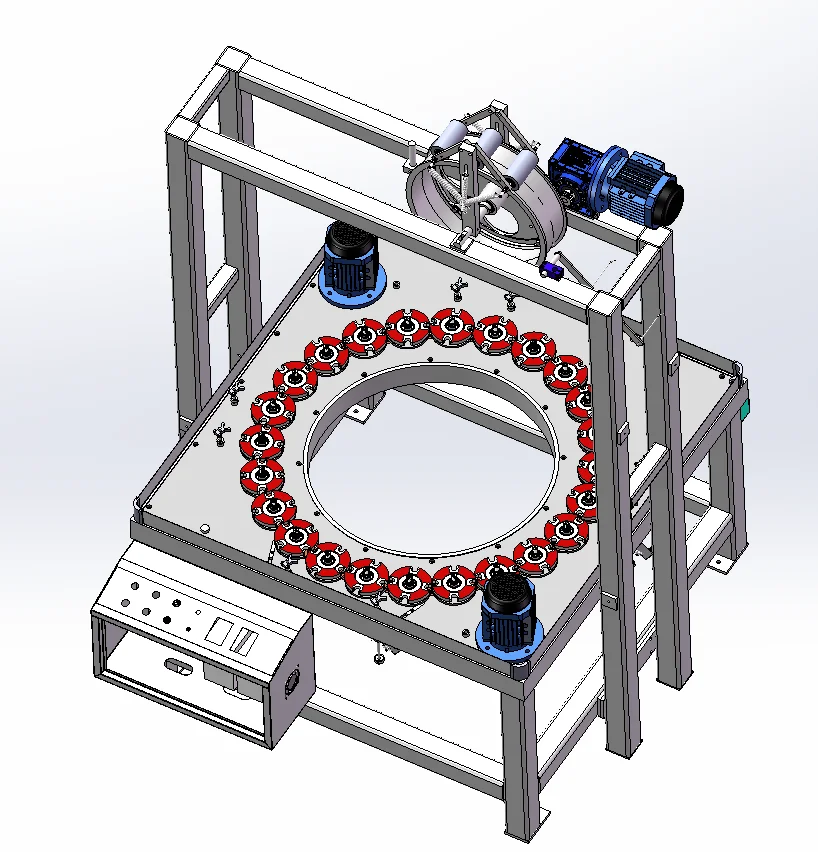

48 Carriers Copper Wire High Speed Braiding Machine

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1601204941878

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 24 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What types of cables can the 48 Carriers Copper Wire High Speed Braiding Machine braid?

This machine is designed to braid a variety of cables including communication cables, signal cables, USB cables, high temperature wires, insulation wires, special cables, and more.

2. What materials can be used with this braiding machine?

The machine can braid with copper, aluminum, magnesium wire, tin wire, stainless steel wire, and various other metal wires, as well as PP, PE, carbon fiber, and fiberglass.

3. What is the maximum braiding diameter that can be achieved?

The maximum braiding diameter is 45 mm, with standard molds available for 35 mm, 40 mm, and 45 mm.

4. What is the spindle speed of the machine?

The spindle speed can reach up to 50 rpm, with a normal production rate of about 80% of the maximum speed.

5. Does the machine have any safety features?

Yes, the machine is equipped with motor overload protection to ensure safe operation during production.

6. Can the machine be customized for different braiding needs?

Yes, multiple configurations are available and the machine can be customized to meet a wide range of braiding needs.

7. What is the overall dimension of the machine?

The overall dimensions of the machine are 2200 mm in length, 1900 mm in width, and 2500 mm in height.

8. What is the power requirement for the machine?

The host power requirement is 5.5 kW.

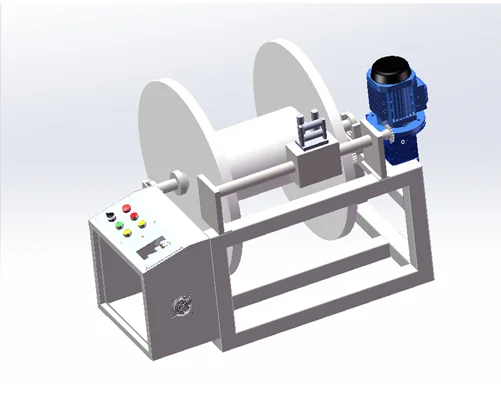

9. What is the purpose of the bunching machine that comes with the setup?

The bunching machine is suitable for stranding copper wires with more than seven strands and is also effective for electronic, power, and network wires.

10. Is there a wire cutting machine included in the setup?

Yes, there is a wire cutting machine that allows you to cut the braided wire to a specified length.

11. What is the bobbin size for the braiding machine?

The bobbin size for the braiding machine is typically 48 mm in diameter and 140 mm in height.

12. How many spindles does the model HH-24 have?

The model HH-24 has a total of 24 spindles, consisting of 12 upper and 12 lower spindles.

13. What is the pitch range for the braiding process?

The pitch range for the braiding process is from 9 mm to 138 mm.

14. Can I use different types of yarns with this machine?

Yes, the machine can be used to braid various yarns, including fiberglass, carbon fiber, and other composite materials by replacing the spindles.

15. What is the weight limit for the spindles?

Each spindle can accommodate a maximum weight of up to 5 kg of copper wire.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading