B21, China Town Mall, Midrand

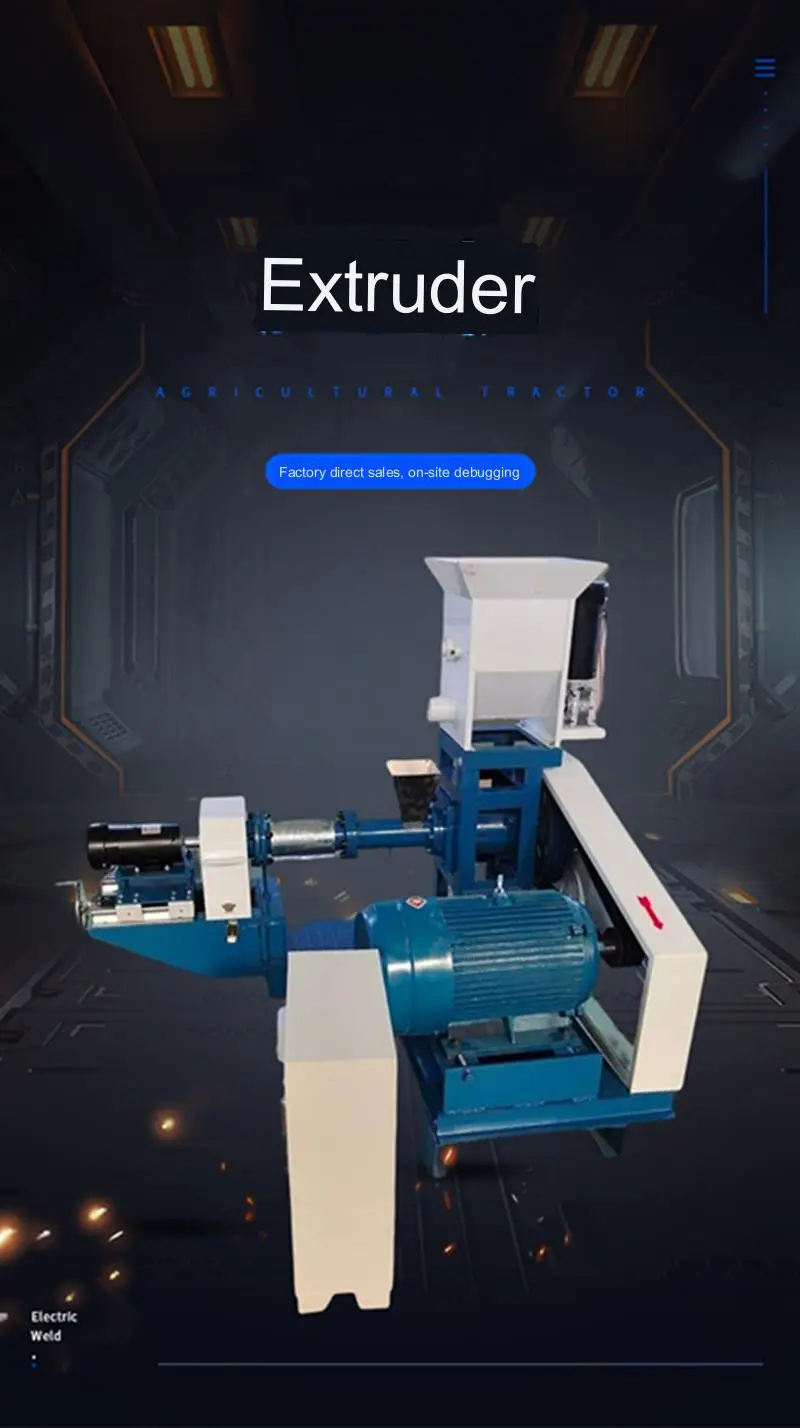

25kg/h Animal Floating Fish Feed Pellet Making Extruder Machine

- Section : Machinery

- Category : Plastic & Rubber Processing Machinery

- SKU : 1600901156335

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 19 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the production capacity of the 25kg/h Animal Floating Fish Feed Pellet Making Extruder Machine?

The nameplate capacity is 25 kg per hour. Actual output varies with raw material, moisture content, formulation and die size; expect variation up to ±20% depending on conditions.

2. What types of feed and raw materials can this extruder process?

It can process cereals and oilseed meals (corn, wheat, soybean), fishmeal, rice bran, insect meal and many single raw materials for puffing. It's suitable for floating fish feed, livestock and poultry feed, pet food and single-ingredient puffed products.

3. What is the difference between the single-screw and twin-screw versions mentioned in the description?

The single-screw extruder is typically used for general feed puffing and single raw-material applications. The twin-screw extruder is better for higher-quality aquatic and pet feeds and for processing viscous or complex formulations because of superior mixing, feeding stability and easier control of residence time.

4. Will the pellets made by this machine float, and how is buoyancy controlled?

Yes — the machine is designed to produce floating (puffed) pellets. Buoyancy is controlled by formulation, inlet moisture, extrusion temperature/pressure and die design; a post-extrusion dryer/cooler and formulation (starch/protein balance) are commonly used to achieve stable floating characteristics.

5. What pellet sizes and shapes can be produced?

Pellet diameter and shape are determined by the die plate. Die plates are interchangeable so you can produce a range of sizes commonly used in fish feed (small to medium diameters). For specific diameters available, request the supplier's die options.

6. Is this a dry or wet extrusion machine, and which should I choose?

The product line includes both dry and wet extruders. Dry extrusion is commonly used for direct puffing of single ingredients and some feeds; wet extrusion (with higher moisture input) is used when different textural properties or downstream drying are required. Choose based on your formulation and downstream equipment.

7. What additional equipment will I need to make finished floating feed pellets?

Typical production includes raw material grinding and mixing, the extruder, and downstream equipment such as a dryer, cooler, screener and optional coating/oiling unit. A pellet cooler and storage/packaging equipment are also commonly used.

8. What are the electrical and power requirements?

Power requirements depend on the specific model and motor options. The best approach is to request the electrical specification sheet from the supplier for the exact model you plan to buy; they will list motor power, voltage and phase requirements.

9. How easy is the machine to operate and maintain?

The machine is designed for farm and small-factory use. Routine operation requires basic training in feeding, temperature and moisture control. Maintenance includes daily cleaning, regular lubrication, and periodic replacement of wear parts (screw, barrel, die). Supplier training and an operation manual are typically provided.

10. What wear parts should I expect to replace, and are spare parts available?

Common wear parts include the screw, barrel, cutting knives and dies. Reputable suppliers provide spare parts and can advise on recommended parts to keep in stock for uninterrupted operation.

11. How do I clean the machine to meet feed hygiene requirements?

Shut down and disconnect power before cleaning. Remove and clean removable parts (dies, cutters, hoppers), clear feed residues from the screw and barrel, and sanitize surfaces that contact product. Frequency depends on product changes and local feed safety rules; follow the supplied cleaning and sanitation guidelines.

12. Can the machine be customized or scaled up?

Yes. Suppliers commonly offer customization (different dies, motor options, control panels) and larger or smaller capacity models. For commercial scaling, discuss required throughput and product specs so the supplier can recommend the correct model.

13. How much does the machine cost and what affects the price?

Price varies with model configuration, accessories (dryer, cooler, mixer), electrical options, customization and order quantity. Contact the supplier/manufacturer for a formal quotation including shipping, installation and any after-sales service.

14. What safety and training provisions should I expect when purchasing?

Expect basic safety features such as guards, emergency stop buttons and interlocks. Reputable suppliers provide an operation manual, recommended safety procedures and options for operator training or commissioning to ensure safe, correct use.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading