B21, China Town Mall, Midrand

1.8m high speed 1pc i3200 print head sublimation

- Section : Consumer Electronics

- Category : DTF Printers

- SKU : 11000006750590

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the maximum printable width of the machine?

The printer supports a maximum printing width of 1.8 meters (1800 mm), making it suitable for large-format media such as banners, textiles and signage.

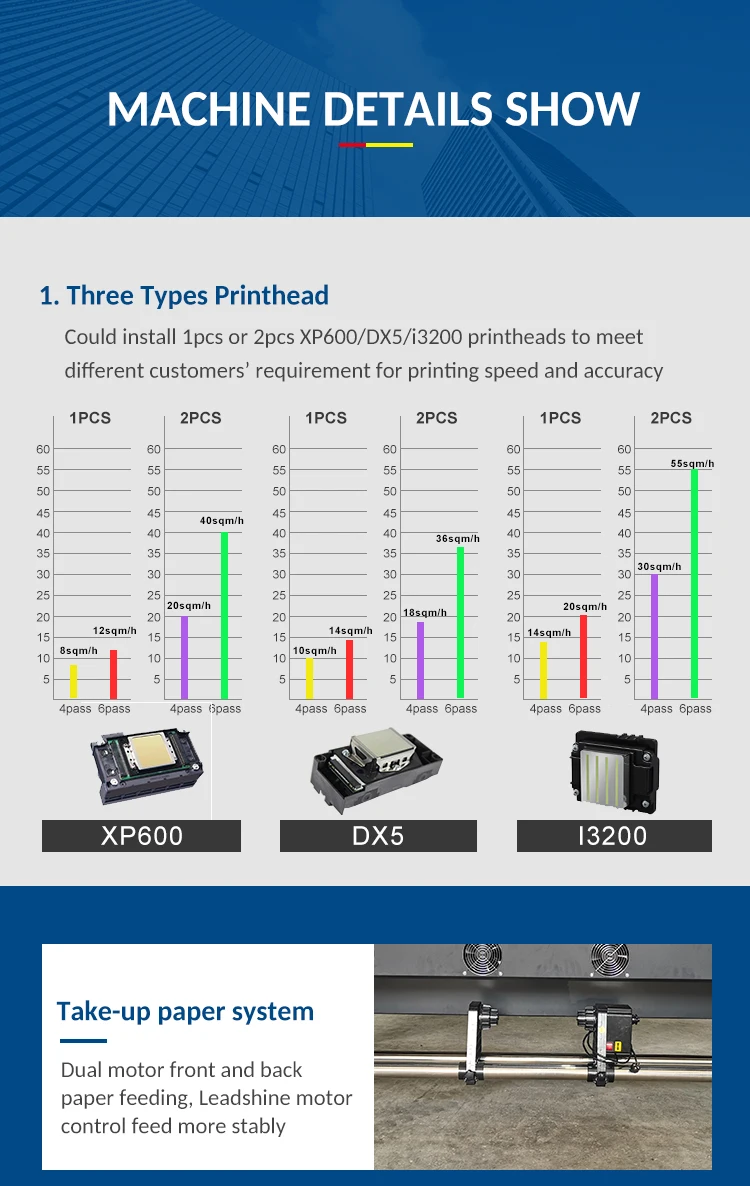

2. Which print head does this machine use and how many?

This model is equipped with one (1pc) I3200 print head, which is designed for high-speed, high-quality output and consistent print performance.

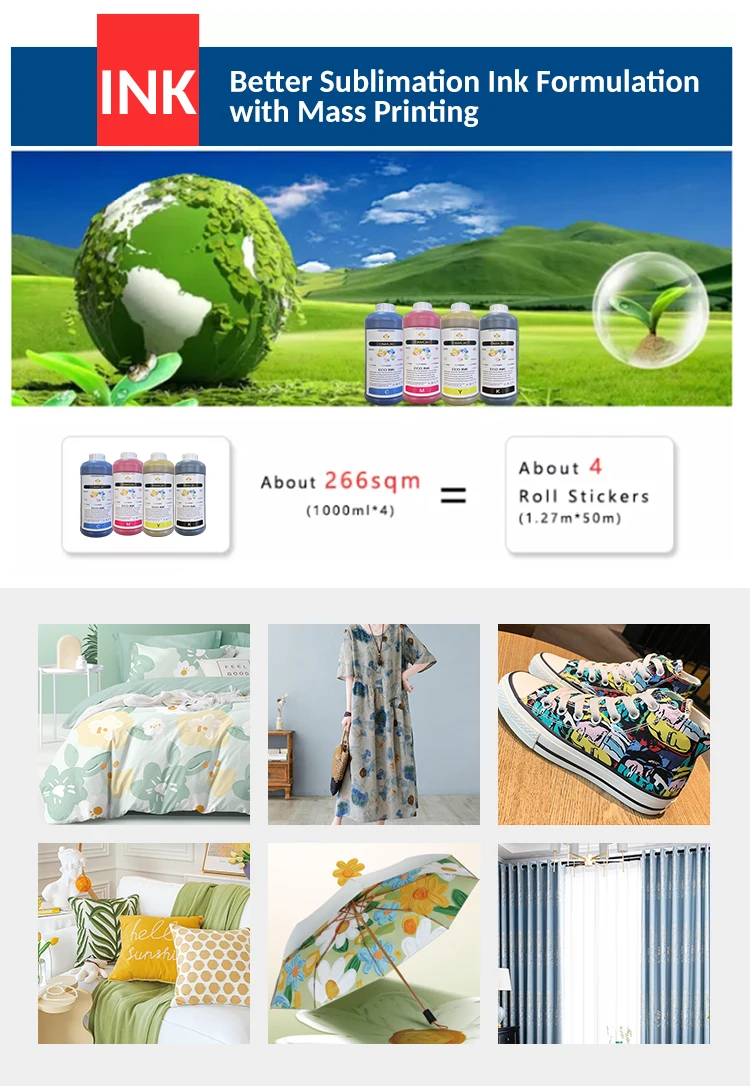

3. What types of ink and media are compatible?

The machine uses dye-sublimation (sublimation) inks and is compatible with a wide range of transfer media including sublimation transfer paper (PP paper), backlit film, wallpaper, vinyl, one-way vision and flex banners intended for dye-sublimation transfer processes.

4. Which file formats does the printer accept?

Supported input formats include PNG, JPG, TIFF, BMP and PDF, allowing flexible use of common image and design files.

5. What color management features are included?

The printer includes ICC-based color control with curve and density adjustment functions for improved color accuracy and consistent results across different media and production runs.

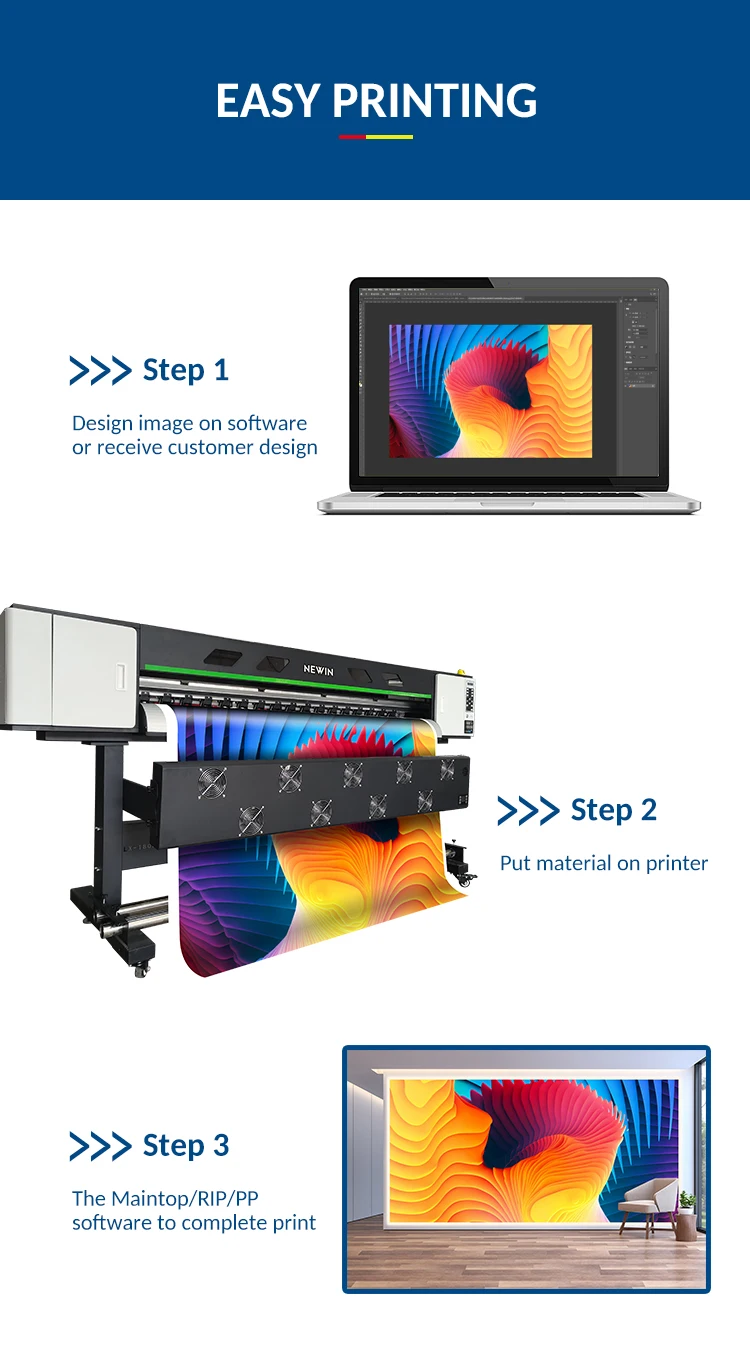

6. Does the machine include RIP software?

Yes. The printer comes with Maintop 6.0 and Photoprint RIP software for advanced color management, layout and print control.

7. What feeding and take-up system does it use?

It features a single-motor feeding and take-up system designed to simplify operation, reduce setup time and provide stable media transport for roll-to-roll production.

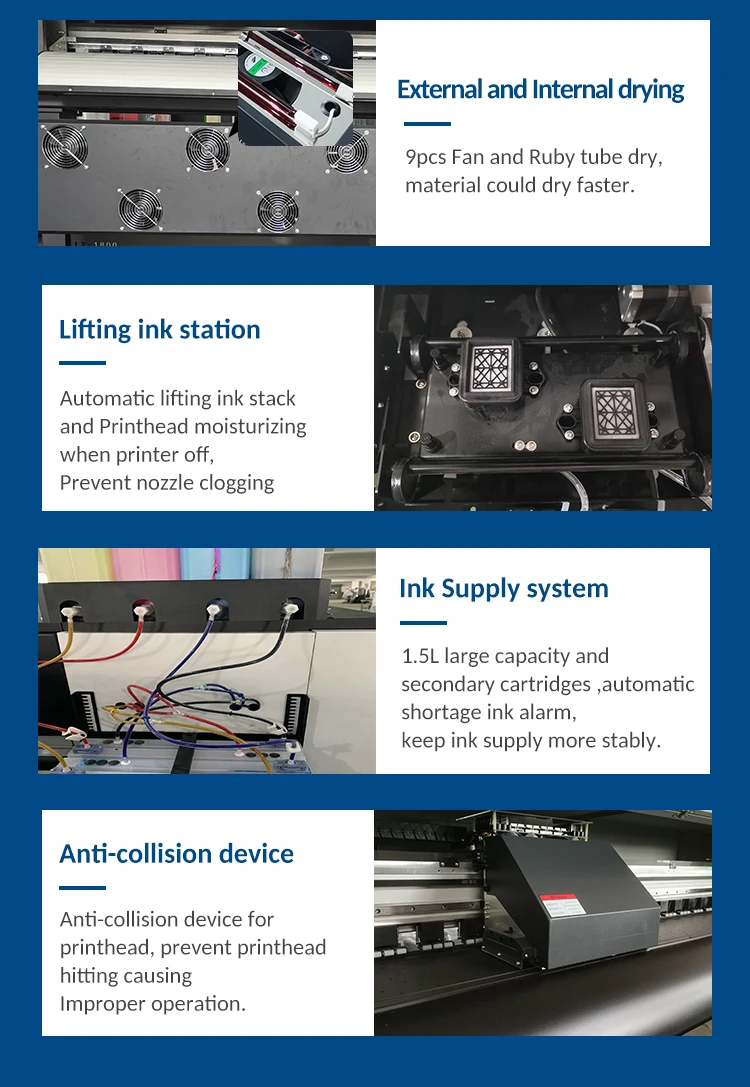

8. What heating and drying systems are provided?

The machine has both front- and back-side heating systems to ensure proper ink transfer and curing, plus an exterior drying system with an infrared heater and fan to speed drying and reduce smudging.

9. What power requirements does the printer have?

The printer operates on 220V power. For exact current draw and electrical setup recommendations, confirm with the supplier or your electrician.

10. What print quality / resolution can I expect and what file resolution should I use?

The I3200 print head is capable of high-quality output. For best results with large-format sublimation work, use high-resolution artwork (commonly 150–300 dpi at final print size). Exact perceived quality will depend on RIP settings, media and viewing distance.

11. How fast is the printer (m²/h or prints per hour)?

The machine is designed for high-speed production, but actual throughput depends on print mode, resolution, color settings and media. For precise speed figures by mode, request the manufacturer’s speed charts or sample-test results.

12. What maintenance and consumables are required?

Routine maintenance includes print-head cleaning cycles, periodic replacement of consumables (sublimation inks, maintenance cartridges, filters and potentially dampers), and keeping the media path clean. Follow the manufacturer’s maintenance schedule to ensure longevity and print stability.

13. What about warranty, installation and training?

Warranty, installation and training policies vary by seller and region. Confirm details with the supplier—many sellers offer on-site installation, operator training and warranty or service packages for an additional fee.

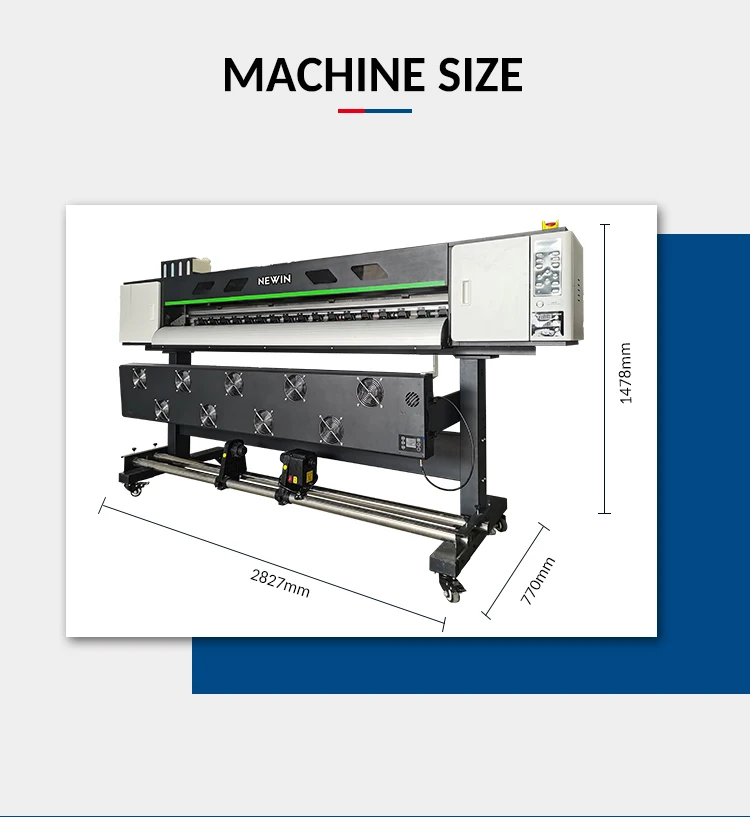

14. What are the machine dimensions and footprint?

A specific compact dimension was listed in the product description but appears to be garbled. Please contact the supplier for the accurate overall dimensions, weight and recommended clearance for installation and ventilation.

15. Is dye-sublimation output wash-resistant and durable on garments?

Yes — when properly transferred onto suitable polyester or polymer-coated substrates, dye-sublimation prints offer vibrant, durable results with excellent wash resistance and color fastness. Ensure you use compatible materials and correct heat-press settings for optimum durability.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading