B21, China Town Mall, Midrand

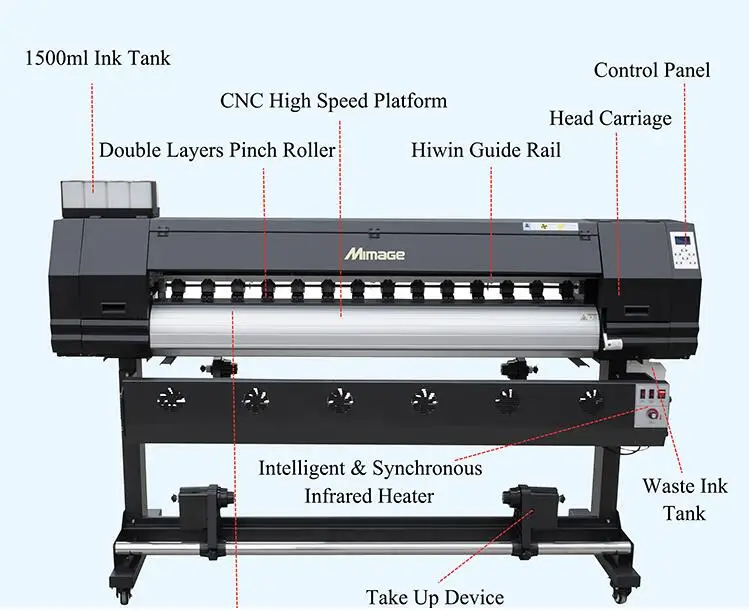

1.8m Head Dye Sublimation Textile Fabric Inkjet Printing Machine with XP600 Head

- Section : Consumer Electronics

- Category : 3D Printers

- SKU : 1600217205764

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the M18 Head Dye Sublimation Textile Fabric Inkjet Printing Machine?

The M18 is a 1.8m (6ft) eco-solvent / dye-sublimation capable wide-format printer introduced by Mimage. It is designed for textile and large-format applications, offering a fashionable black chassis, stable mechanical design and cost-effective operation.

2. What print heads are available or compatible with the M18?

The M18 supports a range of Epson print-head configurations depending on the model/option chosen. Examples include various Epson heads such as DX5, DX11, 4720 and 3200 (different configurations produce different speeds and resolutions).

3. What is the maximum printable width and resolution?

Maximum print width is 1800 mm. Maximum print resolution up to 1440 dpi (actual resolution depends on the selected print-head configuration).

4. What are the print speeds I can expect?

Print speeds vary by head and mode. Typical examples are: Option A – Draft 18.5 sqm/h, Production 15.3 sqm/h, Accuracy 12.8 sqm/h; Option B – Draft 15.9 sqm/h, Production 12.3 sqm/h, Accuracy 8.2 sqm/h; Option C – Draft 21.6 sqm/h, Production 18.1 sqm/h, Accuracy 15.6 sqm/h.

5. What kind of ink does the M18 use and what are the ink capacities?

The M18 uses dye-sublimation ink (CMYK) and employs a negative-pressure continuous ink supply. Each color is supplied from a 1000 ml tank.

6. Which media types can I print on with the M18?

Supported media include water-based media (PP self-adhesive vinyl, backlit film, photo paper, movable PP self-adhesive vinyl, photo cloth) and oily-based media such as photo paper, canvas, car stickers, reflective film and PVC cold lamination film.

7. Does the M18 have heating and drying systems?

Yes. The M18 has fore and after heating systems and a front fan drying system to assist ink fixation and drying for continuous production.

8. How easy is installation and startup?

The M18 is designed for easy installation and startup. The vendor provides an installation manual, step-by-step installation videos and remote support to help you get printing quickly.

9. What software and color management are supported?

The printer supports Maintop and Photoprint (optional) RIP software. Standard ICC profiles have been tested with the printer and inks to ensure optimal color performance; custom profiling is supported for specific workflows.

10. How do I send print jobs to the M18?

Data is transmitted over a network connection — the printer supports network-port printing for workflow integration.

11. What are the electrical and environmental requirements?

Power supply options: 220V or 110V, 50Hz/60Hz. Recommended operating temperature is 15–30°C with relative humidity of 40–60%.

12. What maintenance features does the M18 have?

The M18 includes an automatic cleaning system to maintain print-head health. Routine maintenance (fluid checks, cleaning cycles and periodic head checks) is recommended to ensure optimal performance and longevity.

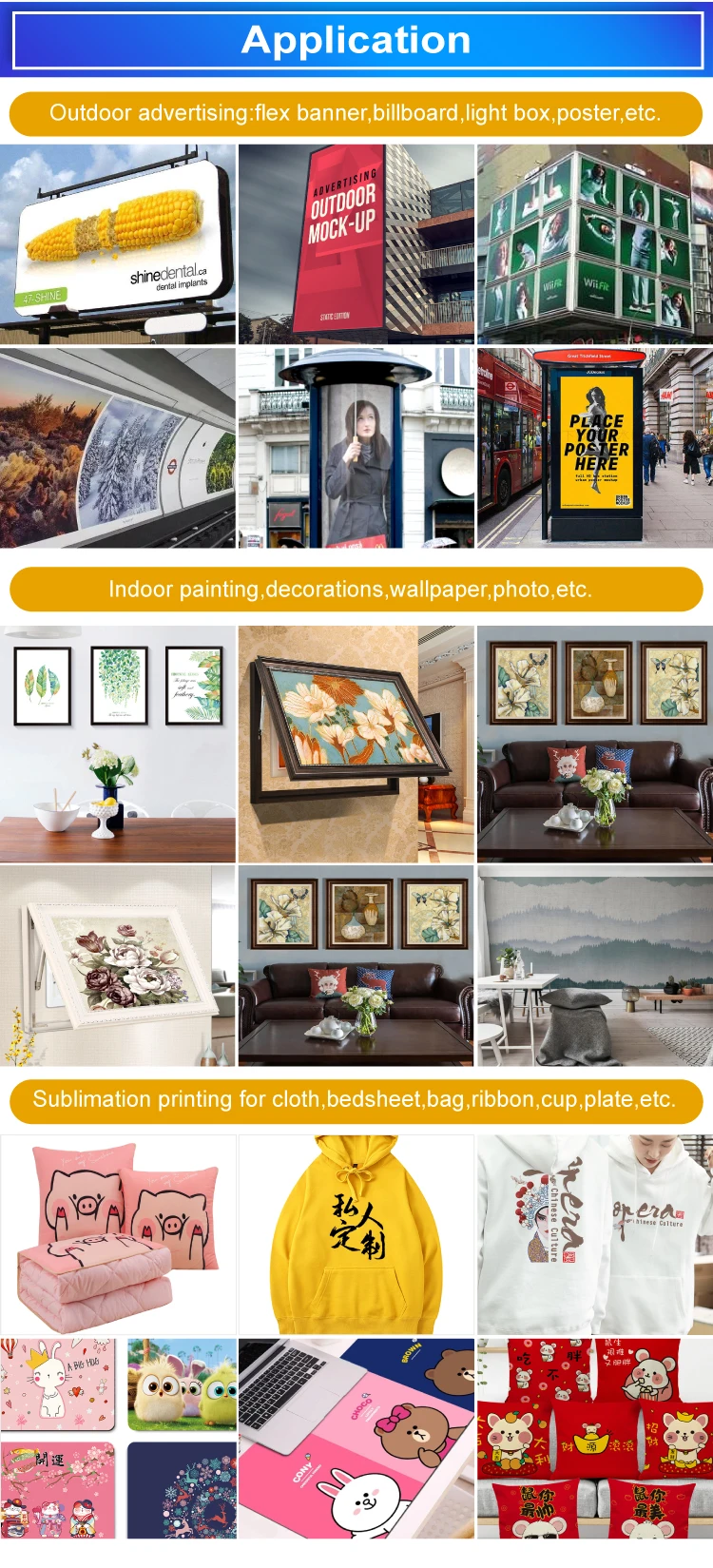

13. What typical applications is the M18 suited for?

Common applications include textile printing, soft signage, backlit displays, vehicle graphics, decals, canvas and photographic prints — essentially wide-format textile and display production.

14. What consumables and spare parts should I plan to keep on hand?

Typical consumables include sublimation ink (CMYK), maintenance fluids, wipers, platen parts, and replacement print-heads or head components as required. Keeping spare ink and routine maintenance items on hand reduces downtime.

15. How do I get technical support, training or spare parts?

The manufacturer/dealer provides installation support, user manuals, installation videos and remote troubleshooting. For parts, service or training, contact your supplier or authorized dealer with machine details and serial number for assistance.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading