B21, China Town Mall, Midrand

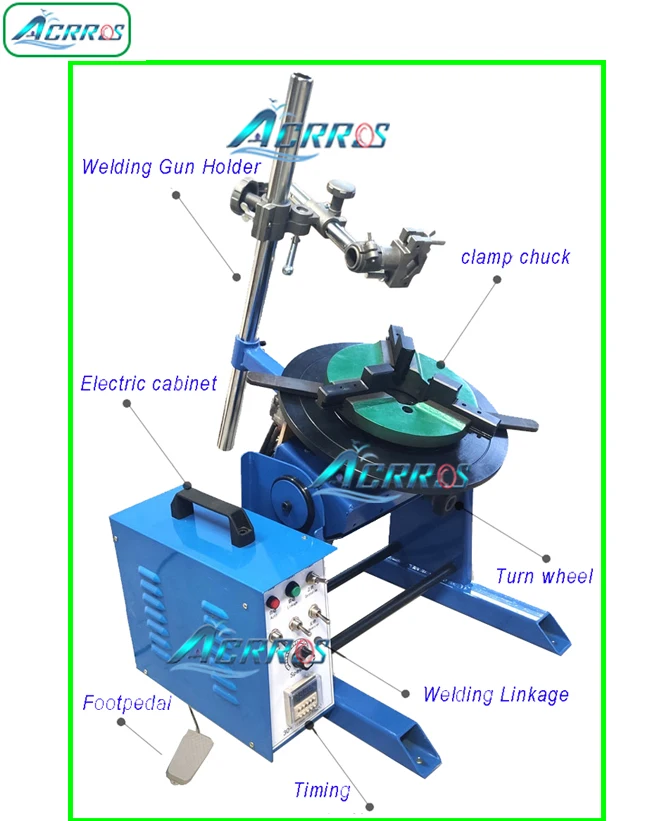

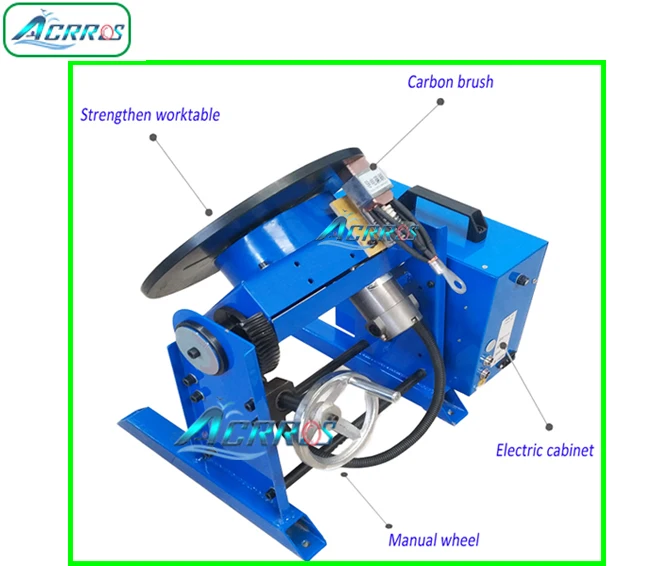

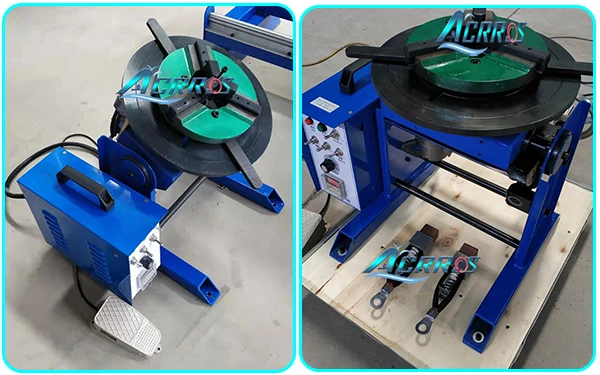

10kg 30kg 50kg 100kg 300kg Positioner Rotary Tig Turntable Automatic Rotating Welding Table For Welding

- Section : Machinery

- Category : Welding Equipment

- SKU : 62058940806

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 14 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What models are available for this rotary welding positioner?

The product is available in seven models: AWP-10, AWP-50, AWP-100, AWP-1.2T, AWP-2T, AWP-5T, and AWP-10T.

2. What are the load capacities for each model?

Load capacities (kg) are: AWP-10: 10/5 (0°/90°), AWP-50: 50/25, AWP-100: 100/50, AWP-1.2T: 1200, AWP-2T: 2000, AWP-5T: 5000, AWP-10T: 10000.

3. What are the rotating speed ranges for the models?

Rotating speed ranges (r/min) are: AWP-10: 2–10, AWP-50: 2–15, AWP-100: 2–15, AWP-1.2T: 0.1–10, AWP-2T: 0.03–0.3, AWP-5T: 0.05–0.5, AWP-10T: 0.05–0.5.

4. Do these positioners have a tilt/overturn function and what are the speeds?

The smaller models (AWP-10, AWP-50, AWP-100) use manual overturning. The heavier models (AWP-1.2T, AWP-2T, AWP-5T, AWP-10T) have an overturning speed of 0.37 r/min.

5. What is the available turning angle for the positioners?

Turning angles are: AWP-10/50/100: 0–90°, and AWP-1.2T/2T/5T/10T: 0–120°.

6. What are the worktable diameters and heights for each model?

Worktable diameter (mm): AWP-10: 177, AWP-50: 340, AWP-100: 340, AWP-1.2T: 1000, AWP-2T: 1100, AWP-5T: 1600, AWP-10T: 2000. Worktable height (mm): AWP-10: 215, AWP-50: 420, AWP-100: 420, AWP-1.2T: 1100, AWP-2T: 1150, AWP-5T: 1450, AWP-10T: 2000.

7. How do I choose the right model for my welding parts?

Select a model with a rated loading greater than your part weight (consider orientation: 0° vs 90° for small models), and ensure the worktable diameter fits the part footprint. For large/heavy parts choose the 1.2T–10T series according to payload and table size.

8. Can the rotating speed be adjusted during welding?

Yes — each model has an adjustable rotating speed range (listed per model). Exact speed control method depends on the controller supplied; contact the seller for details about the control interface and motor drive.

9. Are these positioners suitable for TIG welding?

Yes. The product is described as a Rotary TIG Turntable automatic welding table, designed for TIG and other welding processes where controlled rotation/positioning is required.

10. What installation or foundation is required?

Specific installation requirements (anchoring, foundation, electrical supply) are not listed in the spec sheet. For safe and stable operation, mount on a level, rigid surface and follow the supplier's installation manual — contact the seller for detailed installation instructions.

11. What maintenance is required for these welding positioners?

Regular maintenance typically includes cleaning and lubricating moving parts, checking fasteners and electrical connections, inspecting drive components for wear, and following the manufacturer’s maintenance schedule. Request the maintenance manual from the supplier for model-specific procedures.

12. Can I get custom speeds, sizes, or accessories (chucks/fixtures)?

Customization and accessories are commonly offered for welding positioners. Contact the manufacturer or seller to discuss custom speed ranges, special table diameters, custom fixtures, chucks, or control options.

13. What safety features should be used with this equipment?

Use appropriate guarding, emergency stop, secure workpiece clamping, and follow welding safety practices (PPE, ventilation, grounding). Ensure the positioner is installed and commissioned by qualified personnel and that electrical protections match local codes.

14. Where can I get information on warranty, certifications, and power requirements?

Warranty, certifications (CE, ISO, etc.), and detailed electrical/power specifications are not provided in the brief spec sheet. Contact the supplier or seller for documentation, certification copies, warranty terms, and exact power and control requirements.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Techinical Parameters of Welding Positioner.

Techinical Parameters of Welding Positioner.