B21, China Town Mall, Midrand

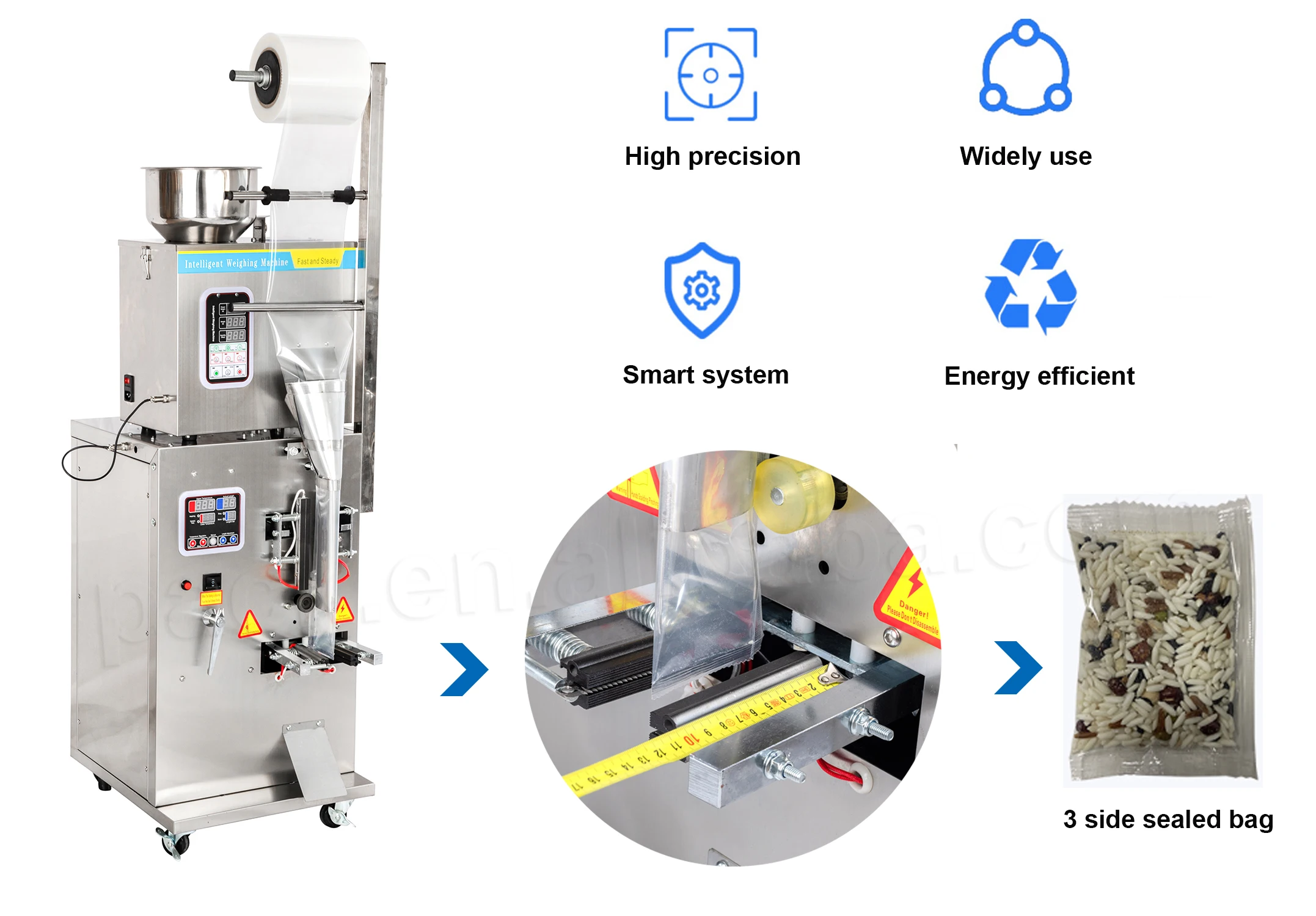

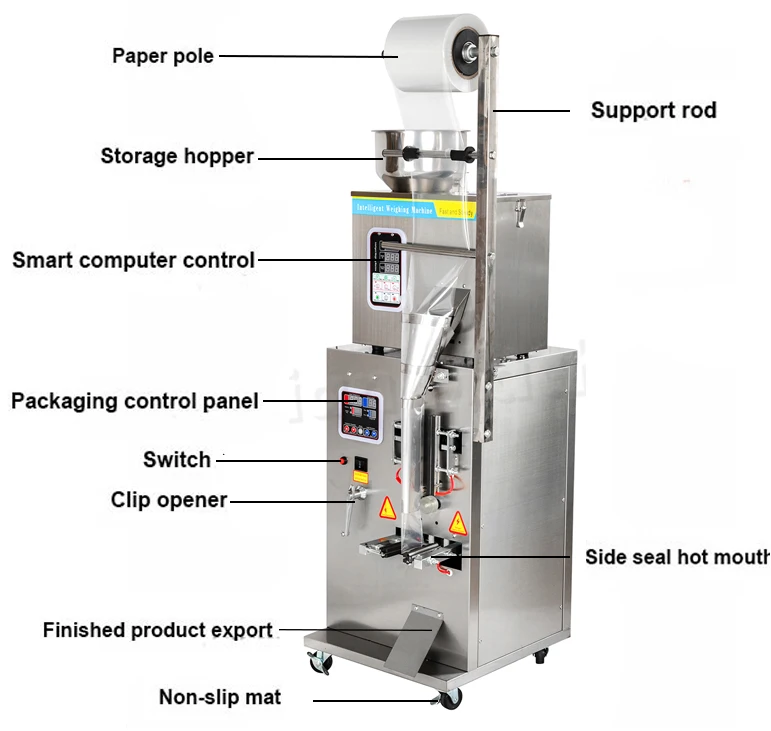

Youlian Automatic Packing Machine

- Section : Machinery

- Category : Packaging Machines

- SKU : 1601008984364

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What industries and product types is the Youlian Automatic Packing Machine suitable for?

The machine is designed for a range of industries with emphasis on food and tobacco. It can pack powders, granules and other small items using compatible packing materials (transparent film, filter paper, aluminum foil film, non-woven fabric).

2. What is the machine's production capacity / packing speed?

Typical high-capacity performance is around 20 bags per minute. Depending on the model and product, filling speed ranges are approximately 10–30 pcs/min (filling unit) and sealing speeds of about 12–25 pcs/min.

3. What filling accuracy does the Youlian machine achieve?

The machine offers precise filling with an accuracy of ±0.02 g, ensuring consistent package weights.

4. What filling ranges are available?

Model-dependent filling ranges include 1–99.9 g, 10–999 g and up to 1–2000 g. Confirm the specific model to match your required fill range.

5. What are the maximum and minimum sealing/package sizes the machine can handle?

Sealing (package) size range: length 20–260 mm and width 30–240 mm. Actual usable range may depend on film type and product; check model specifications before ordering.

6. What are the machine dimensions and weight?

Overall dimensions are 540 mm (W) x 440 mm (D) x 1330 mm (H). Weight depends on the unit: the filling unit is listed as 9 kg and the sealing unit as 33 kg for the referenced configuration.

7. What are the electrical power and voltage requirements?

The machine supports 110/220 V at 50/60 Hz. Rated power is approximately 100 W for the filling unit and 450 W for the sealing unit. Confirm regional voltage and plug requirements with the supplier.

8. What materials is the machine constructed from and is it suitable for food-grade applications?

The machine is constructed from stainless steel, providing durability and ease of cleaning. This construction makes it suitable for food industry use; for formal food-safety certifications, request documentation from the supplier.

9. Which packaging materials are compatible with the Youlian Automatic Packing Machine?

Compatible materials include transparent film, filter paper, aluminum foil film and non-woven fabric. Material choice may affect sealing parameters and machine configuration.

10. Is the machine fully automatic and how is it controlled?

Yes — it is a fully automatic machine equipped with PLC control for easy operation and process monitoring, reducing labor requirements and enabling continuous operation.

11. Can the machine be integrated into an existing production line or fitted with accessories?

Yes. The compact design and PLC control make it suitable for line integration. Optional accessories (conveyors, date printers, check weighers, etc.) may be available—contact the supplier to discuss integration and accessory options.

12. What regular maintenance is required to keep the machine running reliably?

Routine maintenance includes regular cleaning (especially contact surfaces), periodic inspection and tightening of mechanical fasteners, lubrication of moving parts as recommended, and timely replacement of wear parts (seals, cutters, belts). Follow the supplier's maintenance schedule for best results.

13. What kind of after-sales support, training and spare parts availability can I expect?

Typical offerings include installation and commissioning support, operator training, and spare parts supply. Exact warranty terms, support hours and spare parts lead times vary by supplier—check these details with your vendor before purchase.

14. What safety features does the Youlian Automatic Packing Machine include?

The machine is designed with standard industrial safety measures (guarding around moving parts and emergency stop functionality is commonly provided). For a complete list of safety features and compliance with local regulations, confirm with the supplier.

15. Can the machine be customized (e.g., different filling ranges, sealing formats or speeds)?

Yes — models offer different filling ranges, speed options and sealing size capabilities. For custom requirements (special film types, different fill ranges or integration needs), contact the manufacturer or supplier to discuss available configurations and custom solutions.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading