B21, China Town Mall, Midrand

YONGSHUN AHH Centrifugal Slurry Pump

- Section : Electrical & Tools

- Category : Pumps & Parts

- SKU : 1600900051193

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What industries can the YONGSHUN AHH Centrifugal Slurry Pump be used in?

The YONGSHUN AHH Centrifugal Slurry Pump is designed for use in various industries including mining, dredging, chemical processing, power generation, construction, tunneling and drilling, and wastewater treatment.

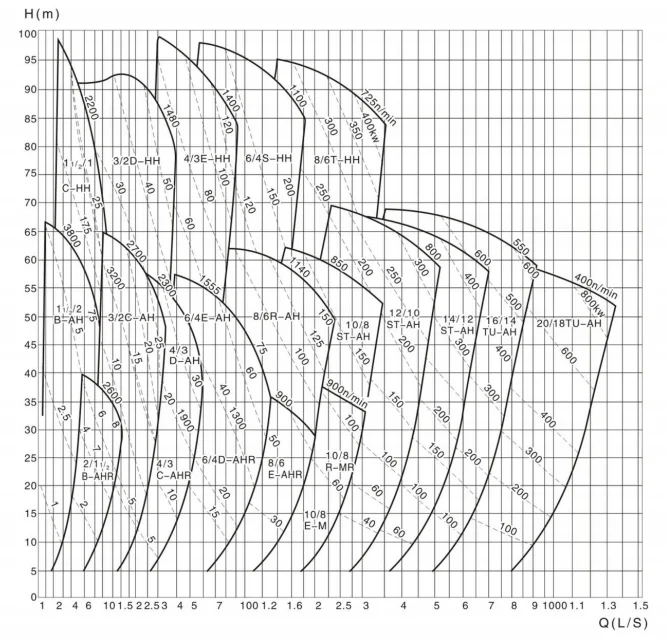

2. What is the flow capacity range of the YONGSHUN AHH pump?

The YONGSHUN AHH pump has a flow capacity range from 3.6 to 2455 m³/h, allowing it to handle large volumes of slurry efficiently.

3. What is the head range that the pump can achieve?

The pump can achieve a head range from 5 to 118 meters, making it suitable for both short and long-distance slurry transportation.

4. What are the speed options for the YONGSHUN AHH pump?

The pump operates at adjustable speeds between 300 to 3800 r/min, providing flexibility for various operational needs.

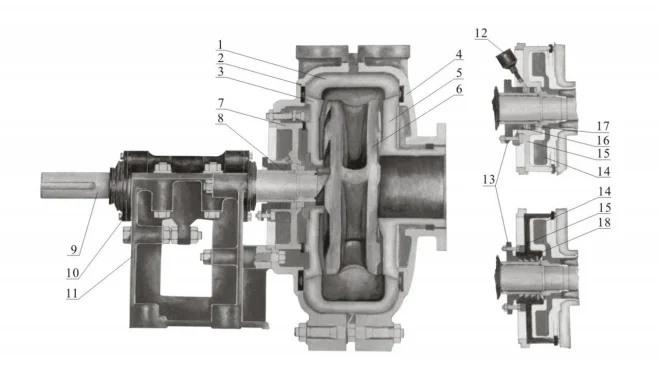

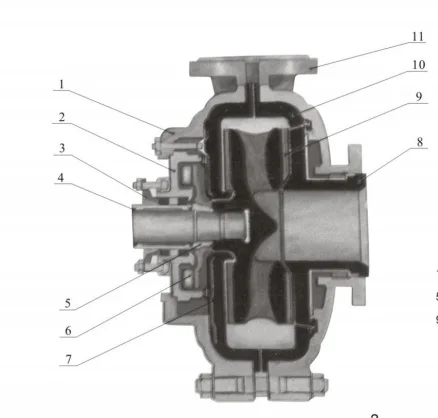

5. What materials are used in the construction of the pump?

The YONGSHUN AHH pump is constructed with durable materials including rubber, high chromium alloy, or custom materials to meet specific project requirements.

6. What types of shaft seals are available for the pump?

The pump offers both packing seal and centrifugal seal options, providing flexibility for different applications and ease of maintenance.

7. Can the pump be customized for specific applications?

Yes, the YONGSHUN AHH pump is highly customizable, with options for outlet size, inlet size, cable length, and color to meet unique project requirements.

8. What is the efficiency range of the YONGSHUN AHH pump?

The efficiency of the YONGSHUN AHH centrifugal pump ranges from 18% to 80%, making it energy-efficient for various slurry pumping needs.

9. What is the NPSHr for the pump?

The pump features an NPSHr (Net Positive Suction Head Required) of 2 to 13 meters, ensuring optimal performance even under challenging suction conditions.

10. What is the maximum horsepower the pump can handle?

The YONGSHUN AHH pump can be powered by up to 750 horsepower, with a power range from 1.5 to 560 kW.

11. How does the pump perform in abrasive environments?

The YONGSHUN AHH pump is specifically designed for handling abrasive and high-concentration slurries, ensuring superior wear resistance and durability.

12. What is the weight of the YONGSHUN AHH pump?

The weight of the YONGSHUN AHH pump is 626 kg.

13. What types of slurries can the pump handle?

The pump is ideal for handling strong abrasion slurries, high-concentration slag slurries, and other challenging industrial materials.

14. What are the dimensions of the pump?

The overall dimensions of the pump are 1021 mm x 812 mm x 668 mm.

15. Is technical support available for this pump?

Yes, technical support is available for the YONGSHUN AHH Centrifugal Slurry Pump, and customers can contact the store for more information.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading