B21, China Town Mall, Midrand

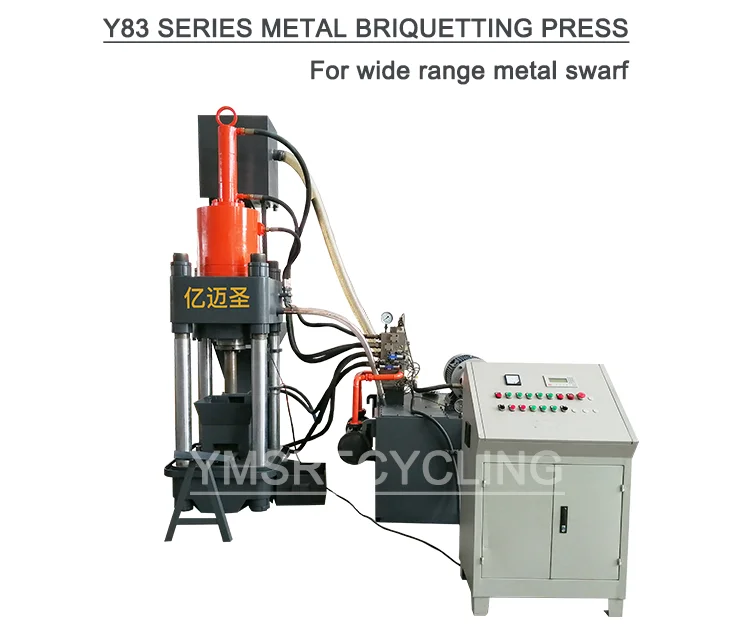

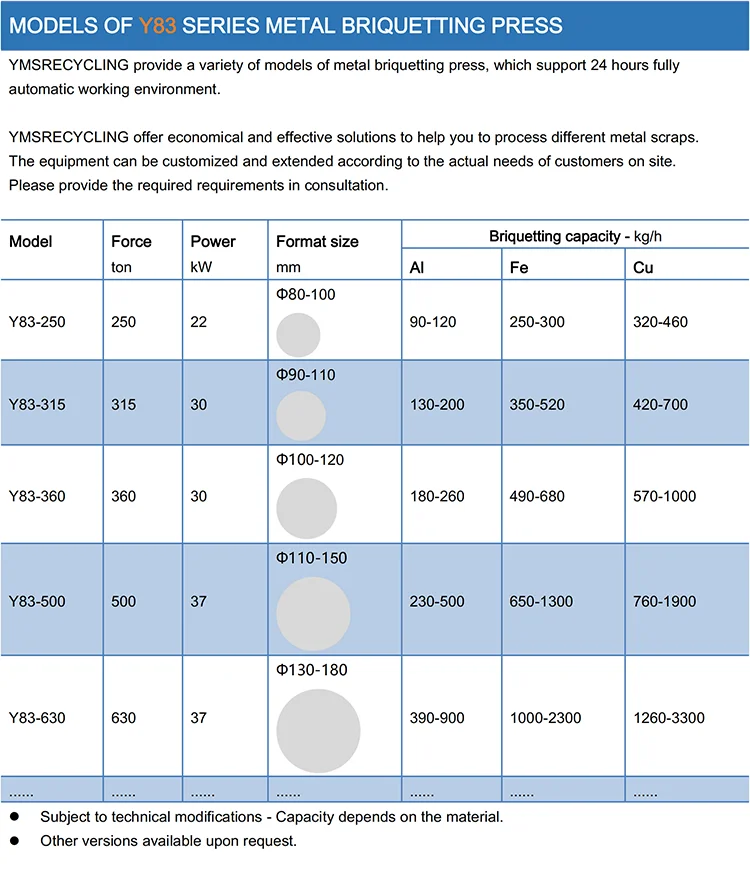

Y83-250 Scrap Metal Aluminum Briquetting Machine – High Efficiency for Metal Shaving Recycling

- Section : Machinery

- Category : Metal & Metallurgy Machinery

- SKU : 1600606558476

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 01 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

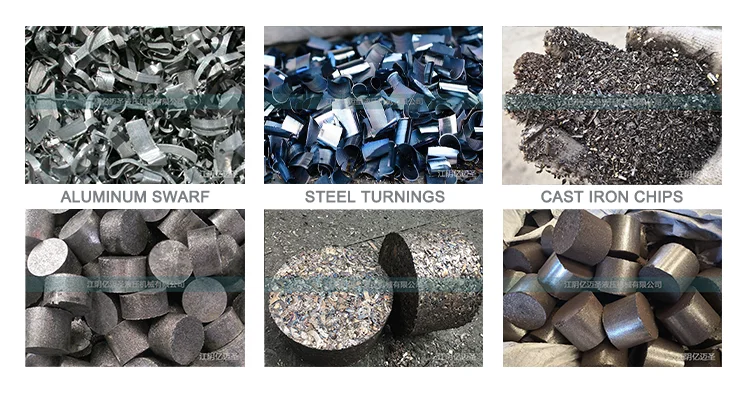

1. What types of materials can the Y83-250 Briquetting Machine process?

The Y83-250 Briquetting Machine is designed to process a variety of metal shavings including aluminum, cast iron, copper, steel, brass, zinc, bronze, titanium, magnesium, lead, and other machining scraps.

2. What is the processing capacity of the Y83-250 machine?

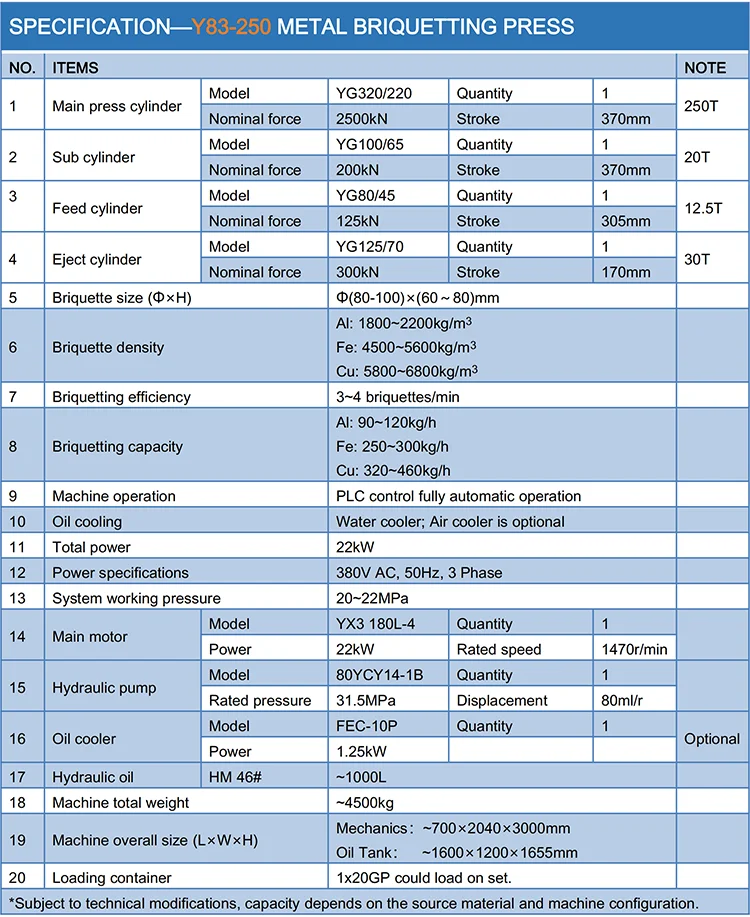

The Y83-250 has a processing capacity of up to 0.5 tons per hour, making it suitable for large-scale recycling operations.

3. How does the automated operation of the Y83-250 work?

The Y83-250 operates automatically using a SIEMENS PLC control system, reducing the need for manual intervention and ensuring consistent and reliable results.

4. Is the Y83-250 easy to operate?

Yes, the Y83-250 is designed for simplicity with a user-friendly interface, allowing operators to use it with minimal training.

5. What is the power rating of the Y83-250's motor?

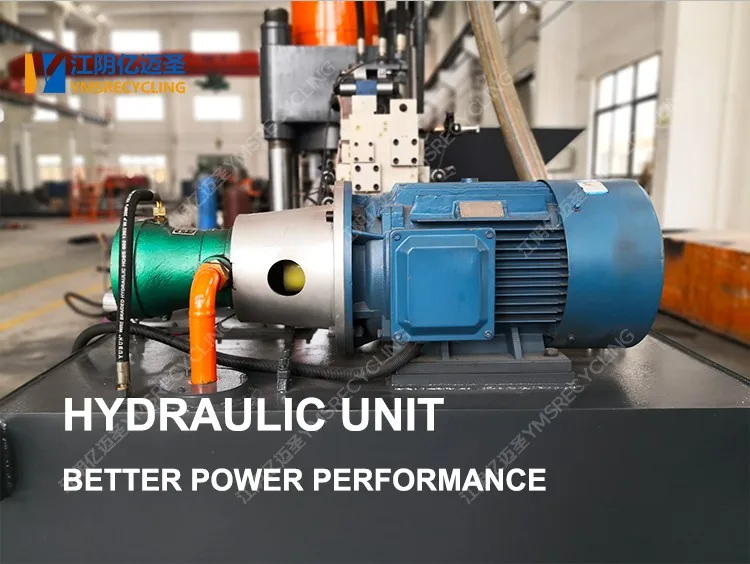

The Y83-250 is equipped with an 18.5kW motor that provides sufficient power for smooth and continuous operation without overheating.

6. Can the voltage of the Y83-250 Briquetting Machine be customized?

Yes, the Y83-250 is available in a 380V configuration with options for customization to suit your specific power requirements.

7. What is the size of the briquettes produced by the Y83-250?

The Y83-250 produces briquettes with a diameter of approximately 100mm.

8. How many briquettes can the Y83-250 produce per minute?

The Y83-250 can produce 3-4 briquettes per minute, depending on the material being processed.

9. Is there a warranty for the Y83-250 machine?

Yes, the Y83-250 comes with a 1-year warranty, providing peace of mind and reliable after-sales support.

10. How does the Y83-250 help in improving storage space?

By compacting metal shavings into dense briquettes, the Y83-250 significantly reduces the volume of scrap metal, thus saving storage space and improving handling efficiency.

11. What kind of maintenance does the Y83-250 require?

Regular maintenance includes checking the hydraulic system, cleaning the machine, and inspecting the motor and components to ensure optimal performance.

12. Can the Y83-250 be used in demanding industrial environments?

Yes, the Y83-250 is built with high-quality components and a robust frame, making it suitable for continuous use in demanding industrial environments.

13. Are there customization options available for the Y83-250?

Yes, the Y83-250 can be customized in color to match your facility’s aesthetics, in addition to voltage customization.

14. What is the maximum size of metal chips that the Y83-250 can process?

The Y83-250 can process metal chips with a maximum size of under 50mm.

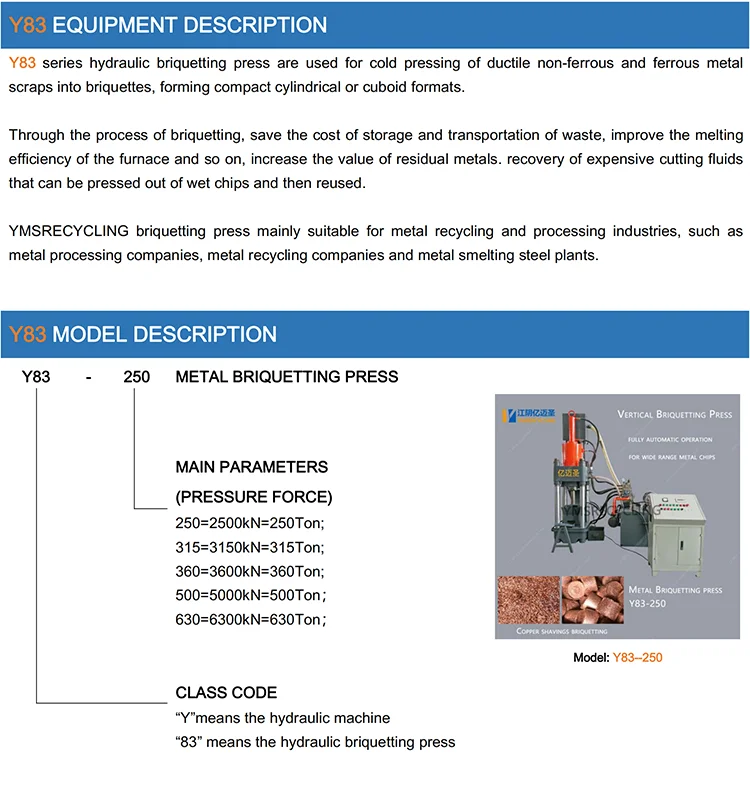

15. What is the main force of the Y83-250 Briquetting Machine?

The Y83-250 has a main force of 2500kN (250 tons), enabling it to compact metal shavings effectively.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading