B21, China Town Mall, Midrand

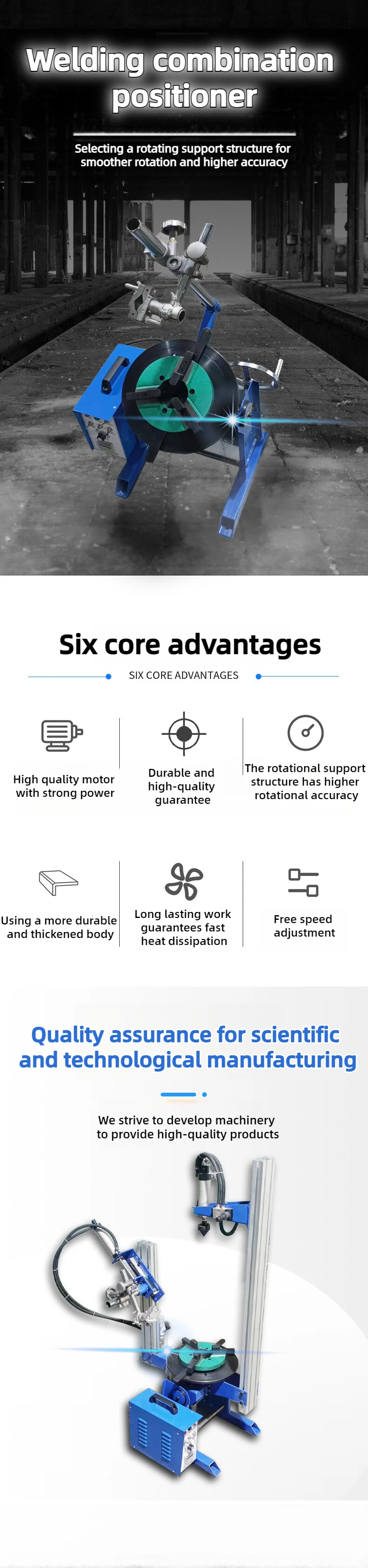

Welding Rotary Positioner Table with Motor Stepper

Model:

- Section : Machinery

- Category : Welding Equipment

- SKU : 996930202022

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 02 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is a Welding Rotary Positioner Table with Motor Stepper?

A welding rotary positioner table with a stepper motor is a rotating workholding table that precisely indexes and rotates a workpiece during welding. The stepper motor provides controlled, repeatable positioning for easier access, improved weld quality, and automation integration.

2. What are the typical applications for this positioner?

Common applications include manual and automated welding (MIG, TIG, stick), brazing, assembly, metal fabrication, inspection, and light machining where precise rotation and indexing of parts are required.

3. What load capacities are available?

Capacities vary by model. Small tabletop units start around 50–200 kg, medium shop units 300–1000 kg, and heavy-duty industrial units can handle several tons. Check the specific model's rated payload for exact figures.

4. How accurate is the positioning and what is the repeatability?

Accuracy and repeatability depend on the stepper motor, driver, gearing, and construction. Typical repeatability is within a fraction of a degree (often ±0.1° to ±0.5°) for well-built systems; exact specifications should be confirmed for each model.

5. Can the table do continuous rotation as well as indexed steps?

Yes. Many units support both continuous rotation for circumferential welding and indexed (step) rotation for stop-and-weld operations. Mode selection is usually handled via the controller or driver settings.

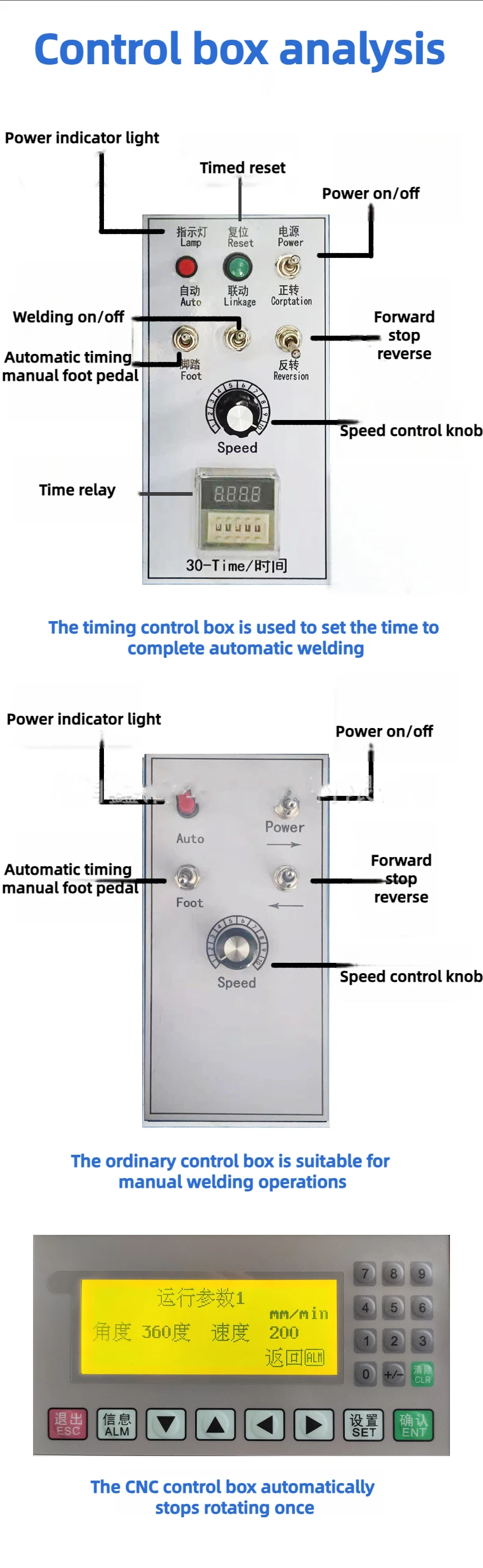

6. What control interfaces are supported?

Common interfaces include pulse/direction inputs for CNC/PLC integration, standalone controllers with keypad or pendant, analog speed control (potentiometer), and I/O for start/stop or foot pedal connections. Custom interfaces can often be provided.

7. What are the electrical and power requirements?

Requirements depend on the stepper motor and driver: many systems run from 24–48 VDC for the control logic and 110–480 VAC for industrial power or mains, with stepper drivers powered by a DC bus. Confirm the model's voltage and phase requirements before installation.

8. How fast can the table rotate and can speed be adjusted?

Speed ranges vary widely; small units may rotate a few RPM up to several hundred RPM on light loads. Stepper-driven tables offer adjustable speed via the controller or driver settings and typically allow fine control over acceleration ramping.

9. Is the turntable size and flange pattern customizable?

Yes. Many manufacturers offer multiple table diameters, custom faceplates, T-slot patterns, and bolt hole configurations to match fixtures, chucks, or specific part geometries.

10. What safety features should I expect?

Standard safety features include emergency-stop integration, torque-limiting or soft-start motion control, mechanical locking or holding brakes, guarding options, and proper electrical grounding. Always follow local safety regulations and integrate guards as needed.

11. How is the positioner installed and aligned?

Installation typically involves mounting the unit on a flat, level surface, bolting it down, connecting the electrical supply and control signals, and verifying alignment with welding fixtures. Leveling feet or shims and mechanical anchors are commonly used.

12. What maintenance is required?

Routine maintenance includes cleaning, periodic lubrication of bearings and gears per the manufacturer's schedule, checking fasteners and electrical connections, inspecting belts/couplings, and keeping the motor/driver cooling vents clear. Replace worn components promptly.

13. Can this positioner be integrated with robotic welding systems?

Yes. Stepper-driven positioners are commonly integrated with robotic systems. Integration typically uses encoder feedback (if fitted), PLC or robot I/O for indexing/handshake, and appropriate safety interlocks.

14. Are accessories and fixturing available?

Yes. Typical accessories include faceplates, chucks, tailstocks, clamps, welding turntable fixtures, pendant controls, foot switches, brakes, and custom tooling. Many suppliers offer accessory packages or custom fixtures.

15. What warranty and lead times should I expect?

Warranties vary by manufacturer but commonly range from 12 to 24 months for parts and limited labor. Lead times depend on stock, customization level, and shipping; standard units may ship in weeks, custom builds can take longer. Confirm exact terms with the supplier.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals