B21, China Town Mall, Midrand

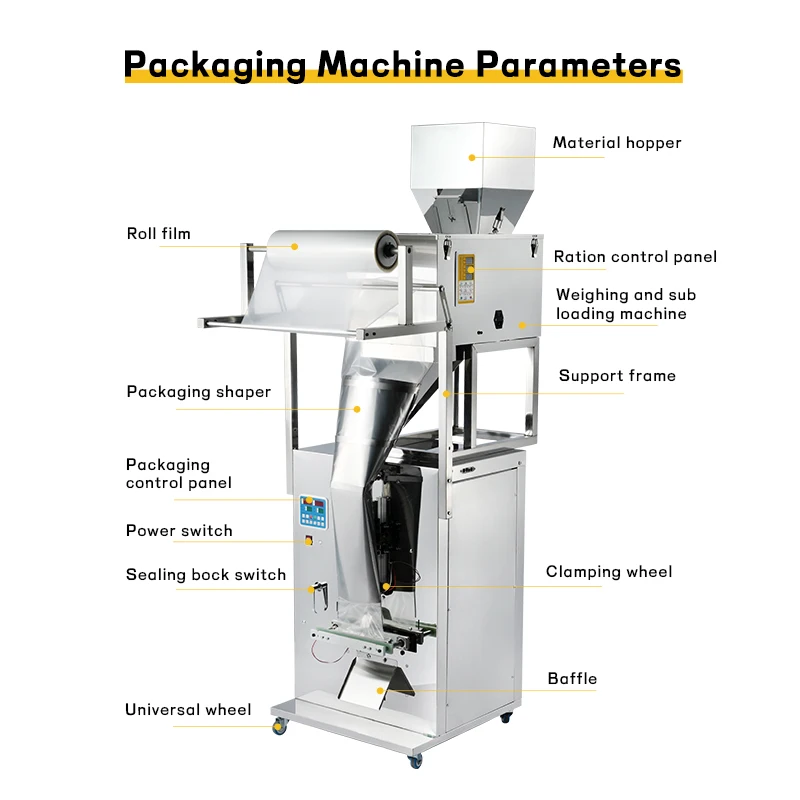

Weighing Detergent Powder Filling Packing Machine For Washing Powder Soap

- Section : Machinery

- Category : Multi-Function Packaging Machines

- SKU : 1600487469072

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 26 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

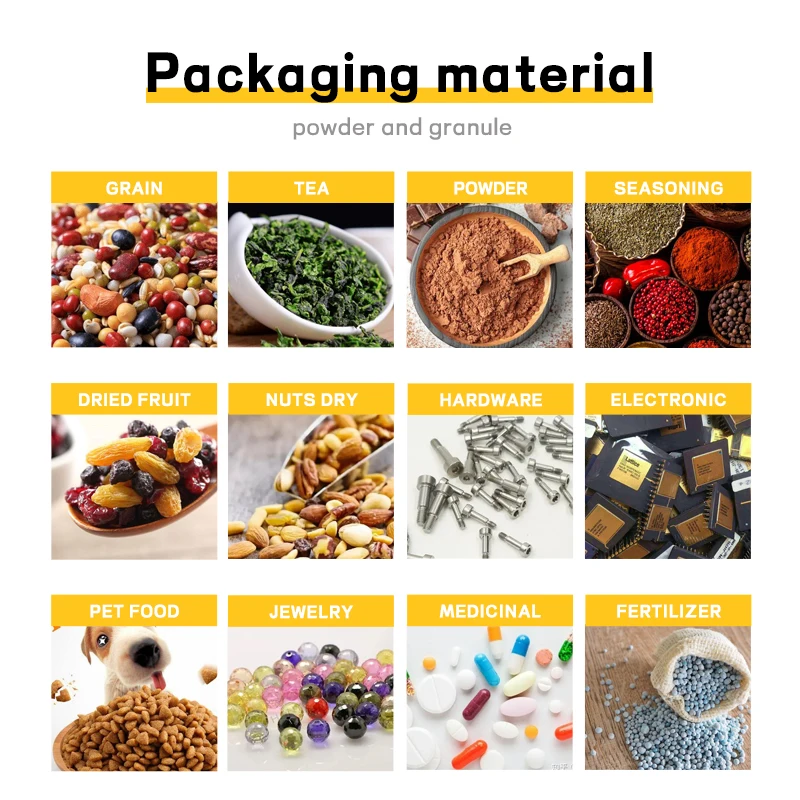

1. What products is this machine designed to pack?

Designed primarily for powders and fine granules such as detergent powder, washing powder and soap powder. It can also handle some other granular and powdered products depending on particle size and flowability.

2. What is the weighing and filling range?

Standard weighing range is 1–100 g. This range can be customized to meet higher or different filling requirements.

3. What is the packaging speed (output) of the machine?

Typical packing speed is 5–18 packages per minute. Actual speed depends on material properties, bag size and chosen configuration.

4. What is the packing accuracy (precision)?

Typical precision is ±0.2 g, though final accuracy depends on material characteristics and the selected weighing system.

5. What bag sizes and film widths are supported?

Bag length range is 3–16 cm and applicable film width is 5–20 cm. Other sizes can be accommodated by customizing the machine.

6. What are the machine dimensions and weight?

Standard machine dimensions are approximately 42 x 50 x 145 cm (other layouts available). Net weight is about 55 kg.

7. What is the machine body material and construction?

The machine body is made of stainless steel suitable for food-grade and household-chemical environments, providing corrosion resistance and easy cleaning.

8. What are the electrical requirements and power consumption?

Standard supply is 220 V / 50 Hz and rated power is around 360 W. Voltage and frequency can be customized to suit local requirements.

9. Can the machine be adapted for different packaging types (pre-made bags, roll film, etc.)?

Yes. The machine can be configured for different packaging styles (VFFS roll film, pre-made pouches, multi-head systems) depending on your production needs—please specify when ordering.

10. Is the machine suitable for both powder and granule products?

Yes. It supports powders and granules, but settings (feeding, vibration, discharge) and sometimes components should be adjusted to suit particle size and flow characteristics.

11. What customization options are available?

Customizable items include weighing range, electrical specifications, bag size, film width, bag type, number of heads, machine dimensions and layout to match your production line.

12. How easy is the machine to clean and maintain?

The stainless steel design and modular components make cleaning straightforward. Routine maintenance includes cleaning the hopper and dosing parts, checking seals and lubricating moving parts. Detailed maintenance instructions are provided with the machine.

13. Do you provide installation, testing and operator training?

Yes. Installation, commissioning and operator training can be provided either at our facility or on-site as part of the purchase agreement (terms and costs depend on location).

14. What lead time, spare parts and after-sales support do you offer?

Lead time and spare-parts availability depend on configuration and order volume. Standard after-sales support includes technical guidance, spare parts supply and remote troubleshooting; extended warranties and on-site service can be arranged.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals