B21, China Town Mall, Midrand

Strong Excavator multifunctional hydraulic stone crusher bucket

- Section : Machinery

- Category : Construction Machinery

- SKU : 1601072535535

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 14 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

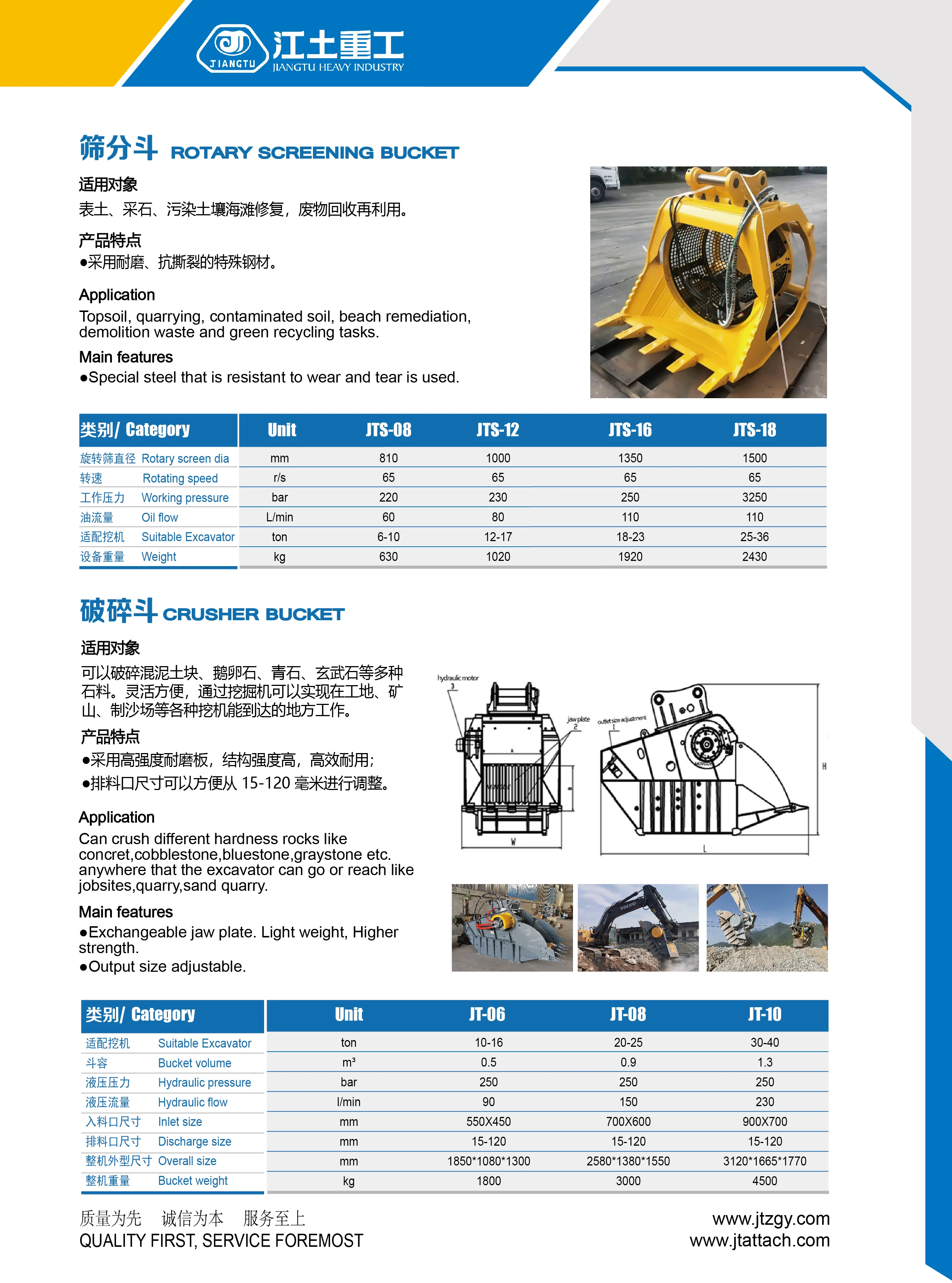

1. What is the Strong Excavator multifunctional hydraulic stone crusher bucket and how does it work?

It is an excavator-mounted crusher bucket that uses the excavator's hydraulic power to operate upper and lower jaws which pinch and crush stone, concrete and construction waste. The crushed material can be sized for reuse and steel rebar is exposed for quick separation.

2. Which machines is this crusher bucket compatible with?

It is designed to mount on typical hydraulic excavators. Compatibility depends on carrier size, pin dimensions and hydraulic flow/pressure. Contact the manufacturer with your excavator model and specs to confirm fit or select the appropriate bucket size.

3. How long does installation take and what is required?

Installation is simple and can be completed in about one hour. You need to add a hydraulic return line to the excavator's oil tank based on existing hydraulic breaker pipeline connections. Follow the manufacturer's installation instructions.

4. What materials can the bucket crush?

It can crush concrete blocks, cobblestones, bluestone, basalt and various construction waste. It also helps quickly separate steel bars from reinforced concrete.

5. What output sizes can be produced and how are they adjusted?

The output size is adjustable from about 15 mm to 120 mm. Adjustment is done per the bucket's settings (screening grate, jaw gap or exchangeable grate/mesh options) — follow the product manual for the exact method and parts required.

6. What is the throughput or production capacity?

Throughput depends on material type, excavator hydraulic power, operator skill and cycle time. There is no single figure that fits all jobs — contact the supplier with your application details for estimated production rates.

7. How does the bucket separate rebar from concrete?

When the jaws crush concrete, the rebar is not fully shredded and becomes exposed or protrudes, making it easy to pick out or remove with the excavator, reducing manual sorting and debris handling.

8. What hydraulic supply does the bucket require?

The bucket uses the excavator's hydraulic system and requires appropriate flow and pressure. Exact requirements vary by bucket model and size. Check the product specifications or consult the manufacturer to confirm your excavator meets the hydraulic flow/pressure and return-line needs.

9. What routine maintenance does the crusher bucket need?

Perform daily visual checks of teeth, wear plates, pins, bushings and hoses. Grease pivot points, inspect hydraulic connections for leaks, tighten bolts as required, and replace worn teeth or liners. Follow the manufacturer's maintenance schedule for hours-based servicing.

10. What are common wear parts and are spare parts available?

Common wear parts include crushing teeth, wear plates, sieves/grates, pins, bushings and hydraulic hoses. Spare parts are typically available from the manufacturer or distributor; order genuine parts for best performance.

11. Are there safety precautions I should follow when using the crusher bucket?

Yes. Isolate and depressurize hydraulics before maintenance, wear PPE, keep personnel clear of the working area, do not exceed excavator or bucket limits, operate at safe cycle rates, and follow the manufacturer's safety guidelines and local regulations.

12. Can this bucket be used to recycle concrete waste directly on-site?

Yes. The bucket is designed to crush and size concrete waste so the crushed material can be reused on-site for backfill, road base or other applications, reducing transport and disposal costs.

13. Is special operator training required?

Operators should be experienced with excavators and trained on the specific attachment, safe operation and maintenance procedures. Many suppliers offer on-site training or operating manuals.

14. How portable and flexible is the crusher bucket in different work environments?

It is very flexible because it works wherever the excavator can reach — construction sites, quarries, mines and sand-making fields. Mobility is limited only by the carrier excavator's reach and transport logistics for the machine.

15. Any tips for transport and storage of the crusher bucket?

Before transport, secure the bucket, drain or block hydraulic lines, and protect exposed components. Store in a dry, covered area to minimize corrosion; support it on blocks to prevent deformation and cover wear surfaces if stored long-term.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading