B21, China Town Mall, Midrand

Strip Tube Essence Filling And Sealing Machine Disposable Hair Mask Precise Ceramic Pump Filling Machinery

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1600479494059

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 29 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is this machine and what products is it designed for?

The HX-005 is an ultrasonic strip/tube filling and sealing machine designed for disposable hair masks, essences and other small-dose products packaged in flat/strip or laminate tubes. It fills, seals and completes packaging operations for single-use tube formats.

2. What are the key specifications of the HX-005?

Key specs: sealing length 140 mm, tube height range 50–150 mm, filling range 1–3 ml, capacity 20–30 tubes/min, 6 working stations, voltage AC 220 V single phase 50/60 Hz, machine size 1300×900×1550 mm, machine net weight 350 kg (400 kg after packaging).

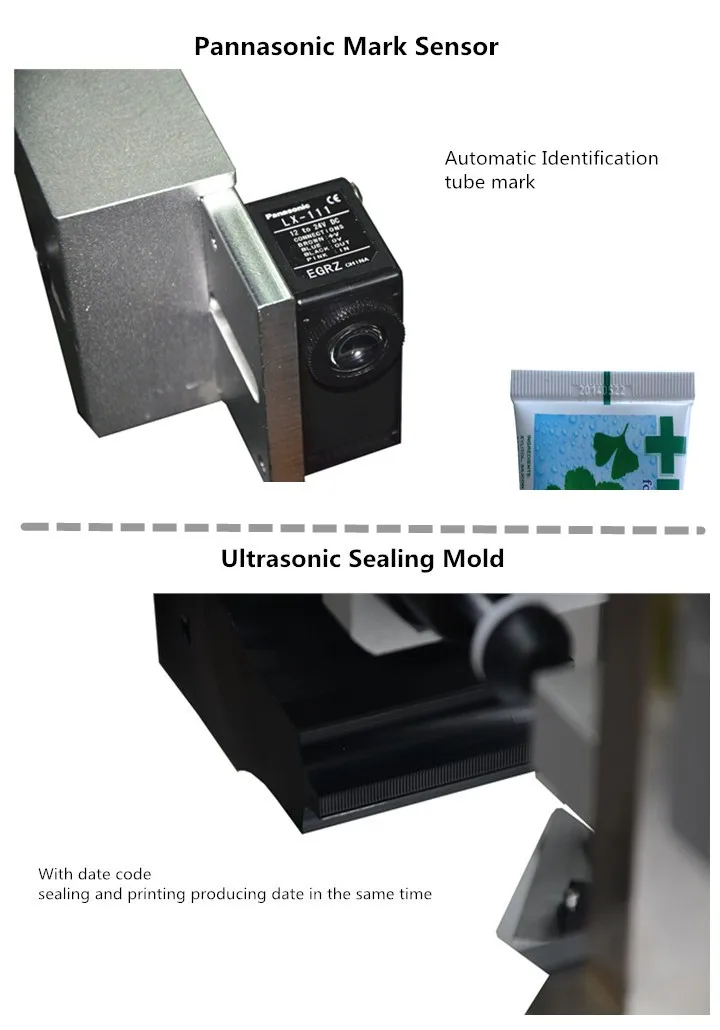

3. What sealing technology does the machine use?

The machine uses ultrasonic sealing, which creates strong seals on compatible laminated or thermoplastic tube materials without needing adhesives or heat bars that contact the product.

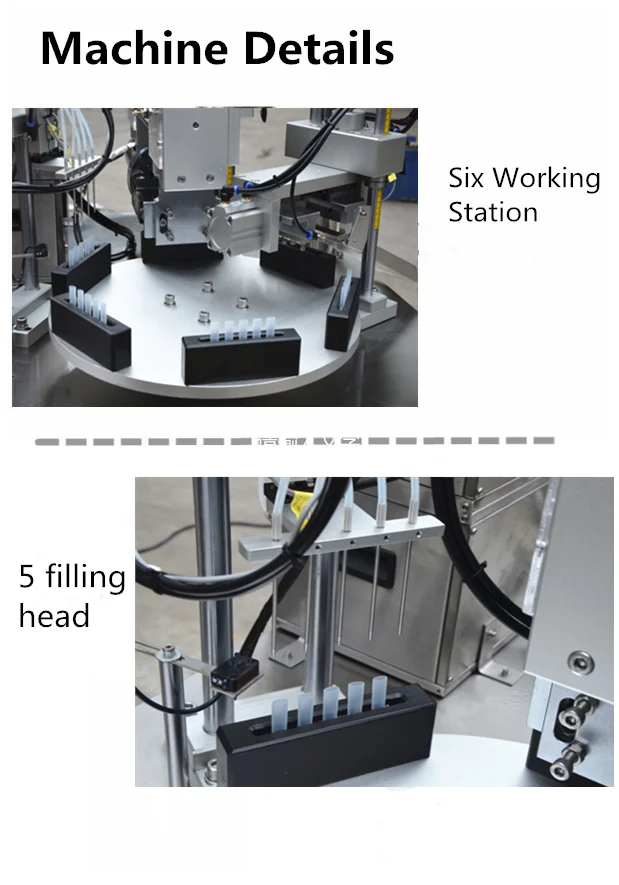

4. What filling mechanism is used and how precise is it?

Filling is performed using a precise ceramic pump system designed for small-volume dosing (1–3 ml). Ceramic pumps offer high dosing accuracy and chemical resistance, delivering consistent fills for viscous hair masks and essences.

5. Which tube types and materials are compatible?

The HX-005 is compatible with common strip/flat tube materials such as single-layer plastics and multi-layer laminated tubes (plastic/aluminum laminates). Compatibility depends on material thickness and composition; please provide sample tubes for confirmation.

6. What is the machine's throughput?

Typical throughput is 20–30 tubes per minute, depending on product viscosity, tube size, operator skill and the selected fill volume.

7. How many working stations does the machine have and why does that matter?

It has 6 working stations. Multiple stations allow sequential operations (loading, filling, sealing, cooling, inspecting, unloading) to run smoothly and increase overall throughput and stability.

8. What are the power requirements?

The machine requires standard single-phase power: AC 220 V, 50/60 Hz. Verify site electrical compatibility prior to installation.

9. How difficult is changeover between tube sizes and how long does it take?

Changeover is relatively quick and typically requires swapping guides, nozzles and adjusting fixtures. Typical changeover time is approximately 5–30 minutes depending on tube size differences and operator experience. Detailed instructions are provided with the machine.

10. What maintenance and cleaning are required?

Routine maintenance includes cleaning the ceramic pump and dosing nozzles after production runs, checking ultrasonic horn and tooling for wear, lubricating mechanical parts per schedule, and inspecting seals. Regular cleaning frequency depends on product viscosity—daily flushing for tacky formulations is recommended.

11. What safety and quality-control features are included?

Common features include emergency stop buttons, safety guards around moving parts, sensors to detect tube presence and proper positioning, and adjustable parameters for fill volume and seal energy to ensure consistent quality. Additional QC checks can be integrated on request.

12. How is the machine packaged and shipped?

The machine is packed in a plywood case for export shipping. Total weight after packaging is approximately 400 kg; crate dimensions are sized to accommodate the 1300×900×1550 mm footprint.

13. Do you provide installation, training and technical support?

Yes. Typically the supplier offers on-site or remote installation guidance, operator training and startup support. Spare parts lists and technical manuals are provided; extended service plans can usually be arranged.

14. Are certifications and warranty information available?

Certification options (CE, UL, etc.) and warranty terms vary by supplier and export market. Please request certificate copies and warranty details from the vendor before purchase so they can be included in the contract.

15. What spare parts and consumables should I expect to need?

Common consumables and spares include ceramic pump parts (seals/rotors), dosing nozzles, ultrasonic horns or caps, O-rings, and tooling pieces/guides for different tube sizes. Suppliers usually offer spare kits and recommended inventory levels based on production volume.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading