B21, China Town Mall, Midrand

Stainless Steel Utensil Cookware PVD Coating Machine Titanium Gold Plating Plant

- Section : Machinery

- Category : Metal & Metallurgy Machinery

- SKU : 60622873090

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 19 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the main function of the Stainless Steel Utensil Cookware PVD Coating Machine?

The main function of the machine is to apply durable and attractive coatings to various substrates, including stainless steel, metal alloys, ceramics, and more, using advanced magnetron sputtering technology.

2. What is PVD coating?

PVD stands for Physical Vapor Deposition, a process used to create thin films and coatings on surfaces. It enhances the aesthetics and durability of products.

3. What types of materials can be coated with this machine?

The machine can coat stainless steel, metal alloys, ceramics, glass, and various other substrates, making it versatile for different applications.

4. What are the available coating colors?

The available coating colors include Silver, Golden, Black, Rose Gold, Pink, Bronze, and Coffee.

5. What is the power requirement for the machine?

The machine requires a power input of 45-150 kW and operates at a voltage of 380V.

6. How does the automatic control system work?

The machine features an automatic PLC touch screen control system that allows for easy operation and monitoring of the coating process.

7. What is the warranty period for this machine?

The machine comes with a warranty period of 1 year, covering manufacturing defects and issues.

8. Can the dimensions of the machine be customized?

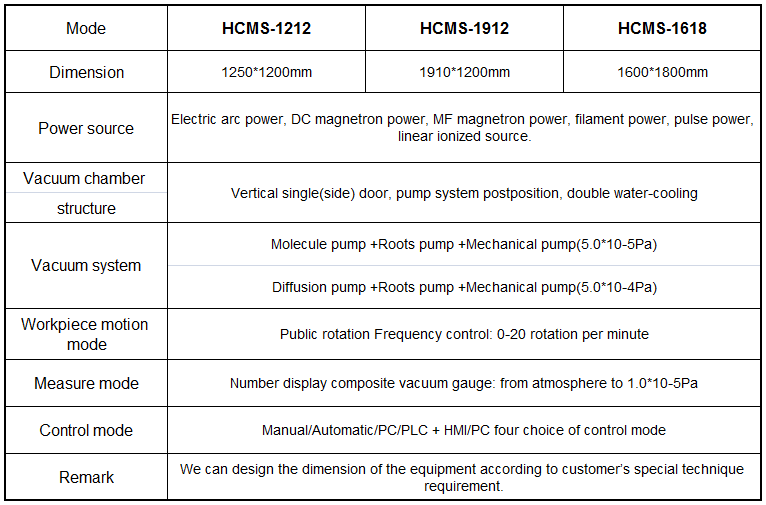

Yes, the machine dimensions can be customized to fit specific business needs and space requirements.

9. What is the weight of the machine?

The Stainless Steel Utensil Cookware PVD Coating Machine weighs approximately 5000 kg.

10. Is the machine suitable for small businesses?

Yes, the machine is designed to enhance product appearance and longevity, making it suitable for both small and large businesses.

11. What certifications does the machine have?

The machine is certified with ISO9001 and TUV, ensuring it meets international quality and safety standards.

12. How long does the coating process take?

The coating process duration can vary based on the substrate and desired finish, but the machine is designed for high-speed coating with optimal PVD homogeneity.

13. What industries can benefit from this machine?

Industries such as manufacturing of home appliances, jewelry, sanitary products, and decorative items can greatly benefit from this machine.

14. What makes this machine reliable and productive?

The machine features high reliability and productivity due to its full automation capability, consistent product quality, and long equipment lifetime.

15. What technology does the machine use?

The machine employs Magnetron Sputtering combined with Multi-Arc Ion Coating technology to achieve superior coating results.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading