B21, China Town Mall, Midrand

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

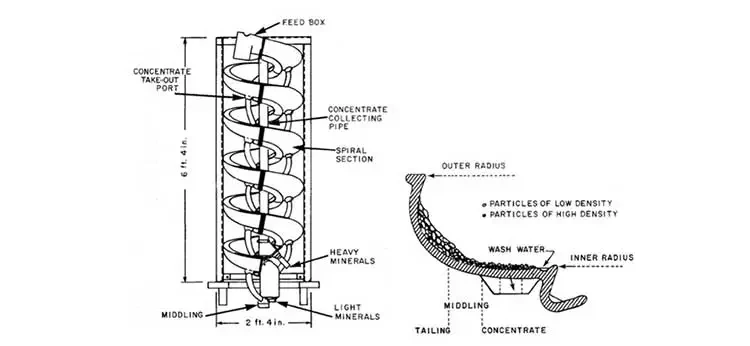

1. What is a Spiral Chute Gold Mining Plant?

The Spiral Chute Gold Mining Plant is a high-efficiency gravity separation equipment that uses centrifugal force to separate light and heavy minerals in ore pulp through a spiral rotation motion.

2. What are the main features of the Spiral Chute?

Key features include a reasonable structure, high recovery efficiency, non-required power, anti-corrosion properties, simple installation, low operating costs, and strong adaptability to varying feed conditions.

3. How does the Spiral Chute work?

The spiral chute operates by raising it to a fixed position where the ore is fed into the inlet, mixed with water to adjust slurry concentration, and then naturally swirled to separate minerals based on gravity and centrifugal force.

4. What materials are used in the construction of the Spiral Chute?

It is made from fiberglass, lined with wear-resistant polyurethane, and covered with corundum, making it light, moisture-proof, anti-rust, and corrosion-resistant.

5. What is the capacity range of the Spiral Chute?

The capacity of the Spiral Chute varies depending on the model, with a range from 0.5 to 45 tons per hour.

6. What is the feeding size for the Spiral Chute?

The feeding size for the Spiral Chute varies by model, ranging from 0.02 mm to 0.4 mm.

7. How much space does a Spiral Chute require for installation?

The area required for installation varies by model, typically ranging from 0.25 to 75 square meters.

8. What is the expected lifespan of the Spiral Chute?

The Spiral Chute is designed for a long working life with minimal maintenance requirements, though the exact lifespan can vary based on usage and conditions.

9. Does the Spiral Chute require any power supply?

No, the Spiral Chute does not require power to operate, relying instead on gravity and centrifugal force for mineral separation.

10. Can the Spiral Chute handle different types of materials?

Yes, the Spiral Chute has strong adaptability to fluctuations in feeding amounts, densities, sizes, and grades of materials.

11. What industries can benefit from using the Spiral Chute?

The Spiral Chute is particularly beneficial for placer mining operations in seashores, riversides, sand beaches, and streams.

12. What maintenance is required for the Spiral Chute?

The Spiral Chute requires minimal maintenance, primarily checks for wear and tear, ensuring the integrity of the fiberglass and other materials.

13. Is the Spiral Chute noisy during operation?

No, the Spiral Chute operates quietly, as it does not require power and relies on gravity for its function.

14. What is the tilt angle of the Spiral Chute?

The tilt angle for the Spiral Chute is typically 9 degrees, which aids in the separation process.

15. How does the Spiral Chute compare to other mining equipment?

The Spiral Chute integrates characteristics from spiral concentrators, shaking tables, and centrifugal concentrators, making it a versatile and effective choice for beneficiation.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading