B21, China Town Mall, Midrand

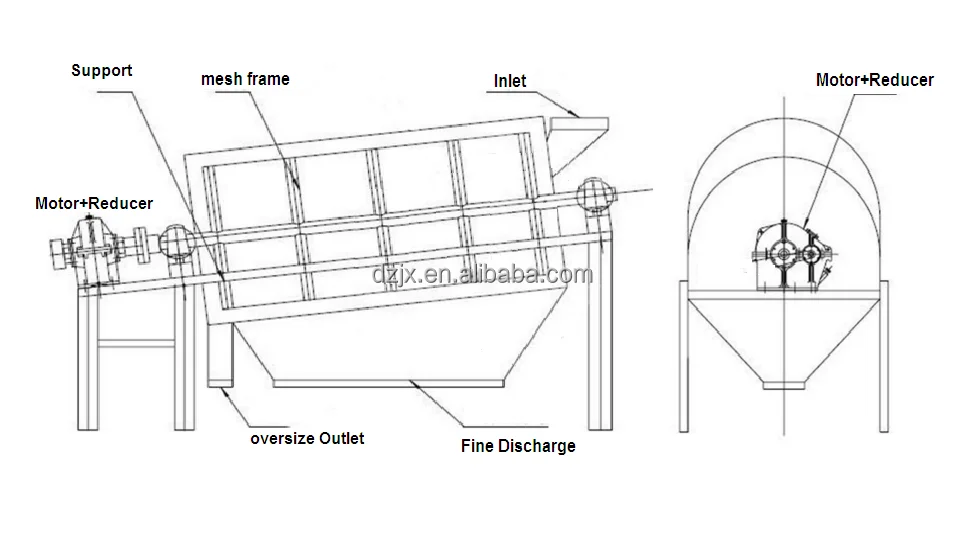

soybean bran compost sieving equipment trommel dirt sifter machine

- Section : Machinery

- Category : Compost Making Machines

- SKU : 1600427997477

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 16 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What industries can the DZ Waste Drum Screen be used in?

The DZ Waste Drum Screen is designed for use in the food, chemical, and mining industries, efficiently separating and sieving materials based on specific particle sizes.

2. What is the customizable drum size range for this machine?

The drum size of the DZ Waste Drum Screen can be customized with diameters ranging from 1000mm to 2000mm and lengths from 1500mm to 5500mm.

3. What screen size adjustments are available?

The screen size can be adjusted from 3mm to 10mm, allowing for precise sorting and separation of particles according to your needs.

4. What materials is the DZ Waste Drum Screen made from?

The machine can be constructed from either carbon steel or stainless steel, depending on your requirements for strength and corrosion resistance.

5. How noisy is the operation of the DZ Waste Drum Screen?

The drum screen operates at noise levels below 75dB, ensuring a quieter working environment, which is particularly important in facilities with strict noise regulations.

6. Can the dimensions of the DZ Waste Drum Screen be customized?

Yes, the overall size of the machine can be customized to fit seamlessly into existing production lines or compact spaces.

7. What type of motor does the DZ Waste Drum Screen use?

The DZ Waste Drum Screen is equipped with a high-performance motor that ensures smooth and efficient operation, even under heavy usage.

8. What is the maintenance requirement for this machine?

The DZ Waste Drum Screen is designed for low maintenance, built with high-quality materials for longevity, which helps reduce downtime and operational costs.

9. Is the DZ Waste Drum Screen easy to operate?

Yes, the machine features a user-friendly design that allows for easy setup and operation, making it simple to incorporate into existing workflows.

10. How is the quality of the DZ Waste Drum Screen ensured?

Each machine undergoes a video inspection and is accompanied by a machinery test report to ensure it meets quality and safety standards before use.

11. What are the applications of the DZ Waste Drum Screen?

Applications include sorting grains, spices, and other food items in the food industry; screening chemicals and raw materials in the chemical industry; and separating minerals and ores in the mining industry.

12. What technical parameters should I know about the DZ Waste Drum Screen?

The machine has various models with different power ratings, drum diameters, lengths, screen sizes, and overall dimensions. Please refer to the product specifications for detailed information.

13. What should I do if I need a specific customization?

For specific customizations, please contact our sales team to discuss your requirements and we will work with you to tailor the machine to your needs.

14. Does the DZ Waste Drum Screen require special installation?

While the machine is designed for easy setup, we recommend referring to the user manual for installation guidelines or consulting a professional for optimal placement within your production line.

15. What is the expected lifespan of the DZ Waste Drum Screen?

With proper care and maintenance, the DZ Waste Drum Screen is built to last, providing reliable performance over an extended period due to its durable construction.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading