B21, China Town Mall, Midrand

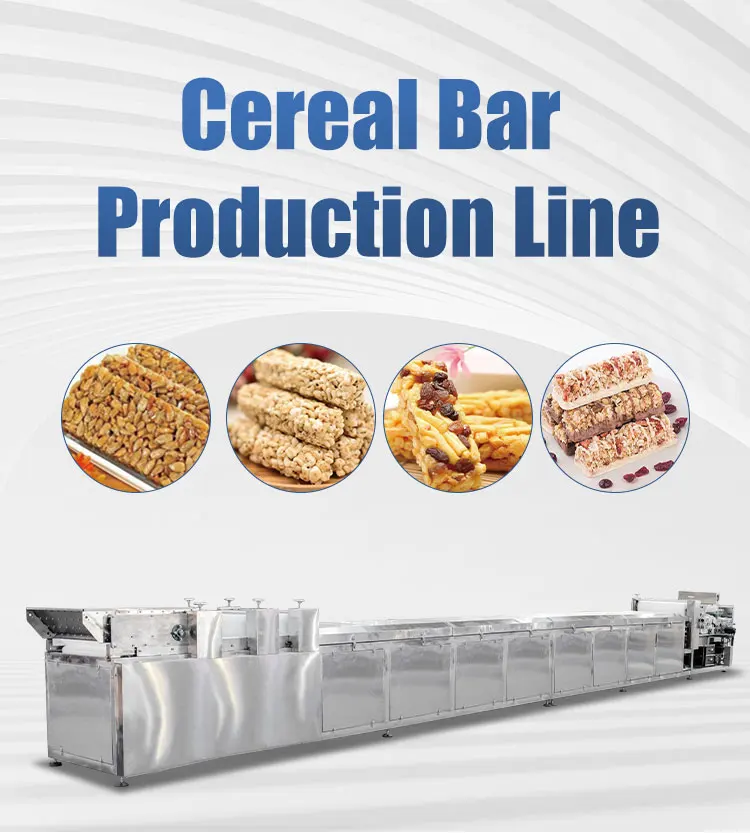

Snack Protein Peanut Candy Brittle Bar Equipment Energy Muesli Bar Making Cereal Bar Machine

- Section : Machinery

- Category : Snack Machines

- SKU : 1600189616384

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 06 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

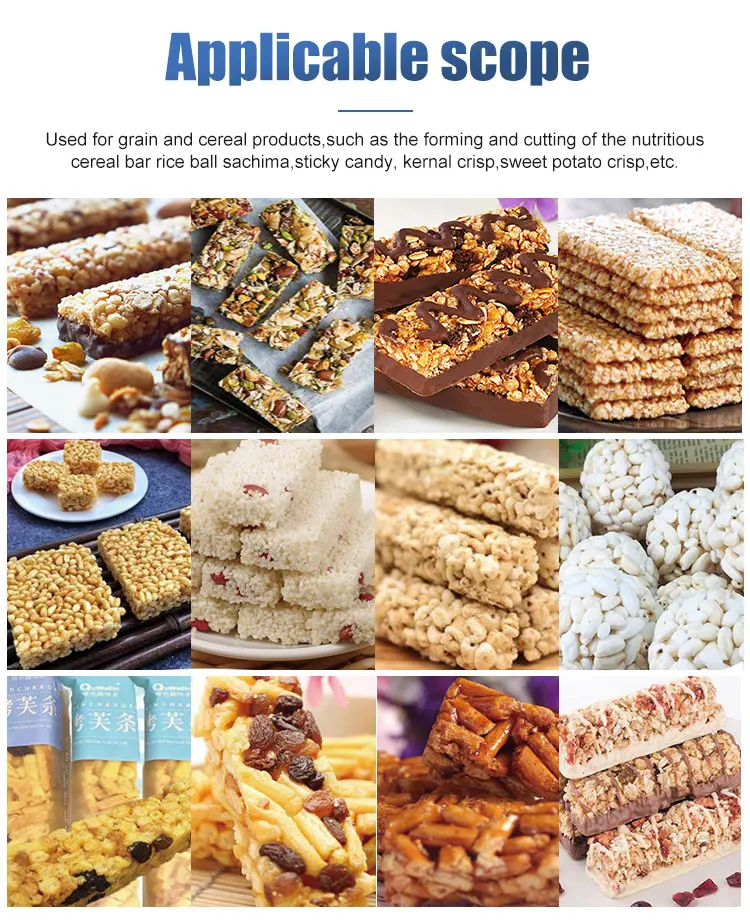

1. What types of bars can I produce with this machine?

The machine is designed to produce a variety of bars including nutrition cereal bars, energy bars, protein bars, and nut bars.

2. How does the active cooling function work?

The active cooling function is integrated into the machine to effectively cool granular and powdered products, ensuring optimal consistency and quality.

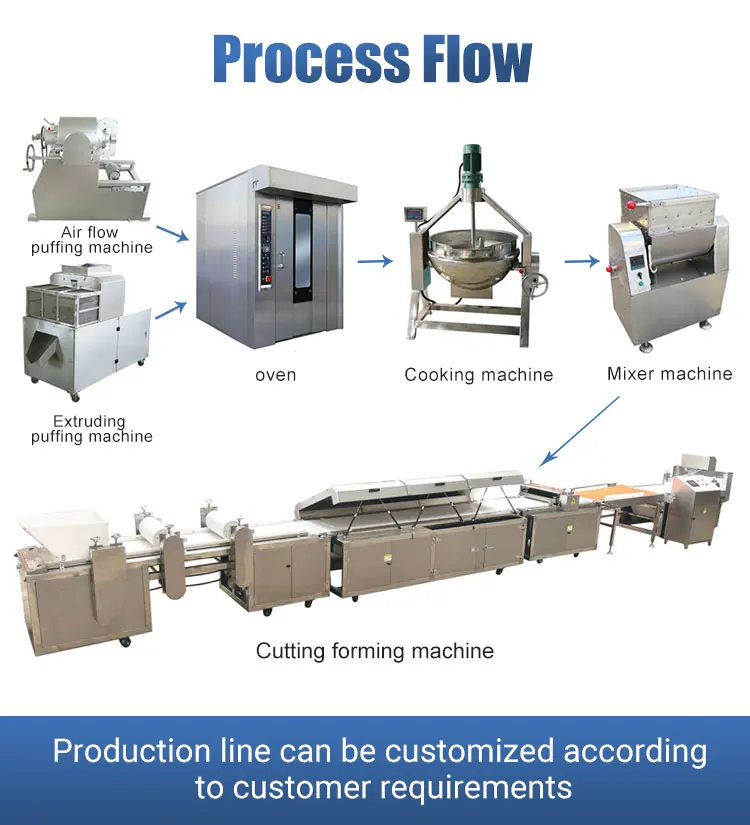

3. Is the production process fully automated?

Yes, the production process is fully automated, including mixing, feeding, leveling, cutting, layering, and packaging.

4. What is the maximum output capacity of the machine?

The output capacity can vary based on the specific model and configuration, but it is designed for high efficiency to meet the demands of food manufacturers.

5. Can I adjust the specifications for different bar sizes?

Yes, the machine features adjustable forming specifications, allowing you to produce bars of various sizes and thicknesses.

6. What materials can be used in the production process?

The machine can handle a range of materials including grains, nuts, seeds, and other ingredients suitable for energy and nutrition bars.

7. Is there a user manual provided with the machine?

Yes, the machine comes with a comprehensive user manual that provides detailed instructions for operation and maintenance.

8. How easy is it to maintain the machine?

The machine is designed for easy operation and maintenance, with accessible components for cleaning and servicing.

9. What safety features are included in the machine?

The machine includes various safety features such as emergency stops, safety guards, and automatic shutoff systems to ensure safe operation.

10. Can the machine handle multiple ingredients at once?

Yes, the machine is capable of continuously feeding and mixing multiple ingredients simultaneously.

11. What is the power requirement for this machine?

Power requirements can vary based on the model; please refer to the specifications section of the user manual for exact details.

12. Is training available for operating the machine?

Yes, training can be provided upon request to ensure that operators are fully equipped to use the machine effectively.

13. What is the warranty period for the machine?

The warranty period varies by manufacturer; typically, a standard warranty covers defects and operational issues for a specified period.

14. Can I see a demonstration of the machine before purchasing?

Many manufacturers offer demonstrations either in-person or via video; please contact the sales team for arrangements.

15. What is the delivery time for the machine?

Delivery time can vary based on location and availability; typically, it ranges from a few weeks to a couple of months.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading