B21, China Town Mall, Midrand

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 29 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

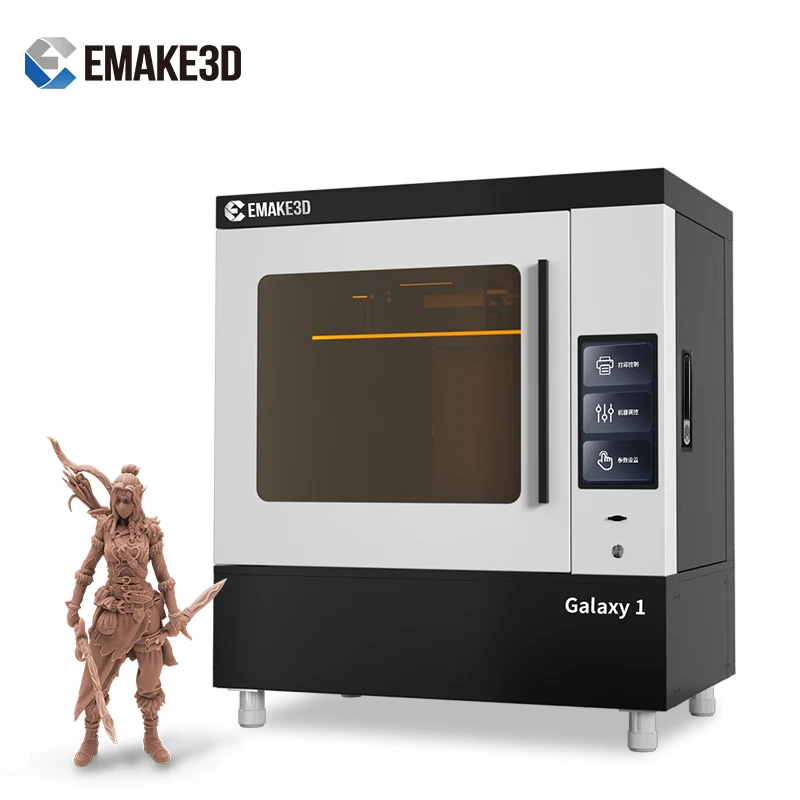

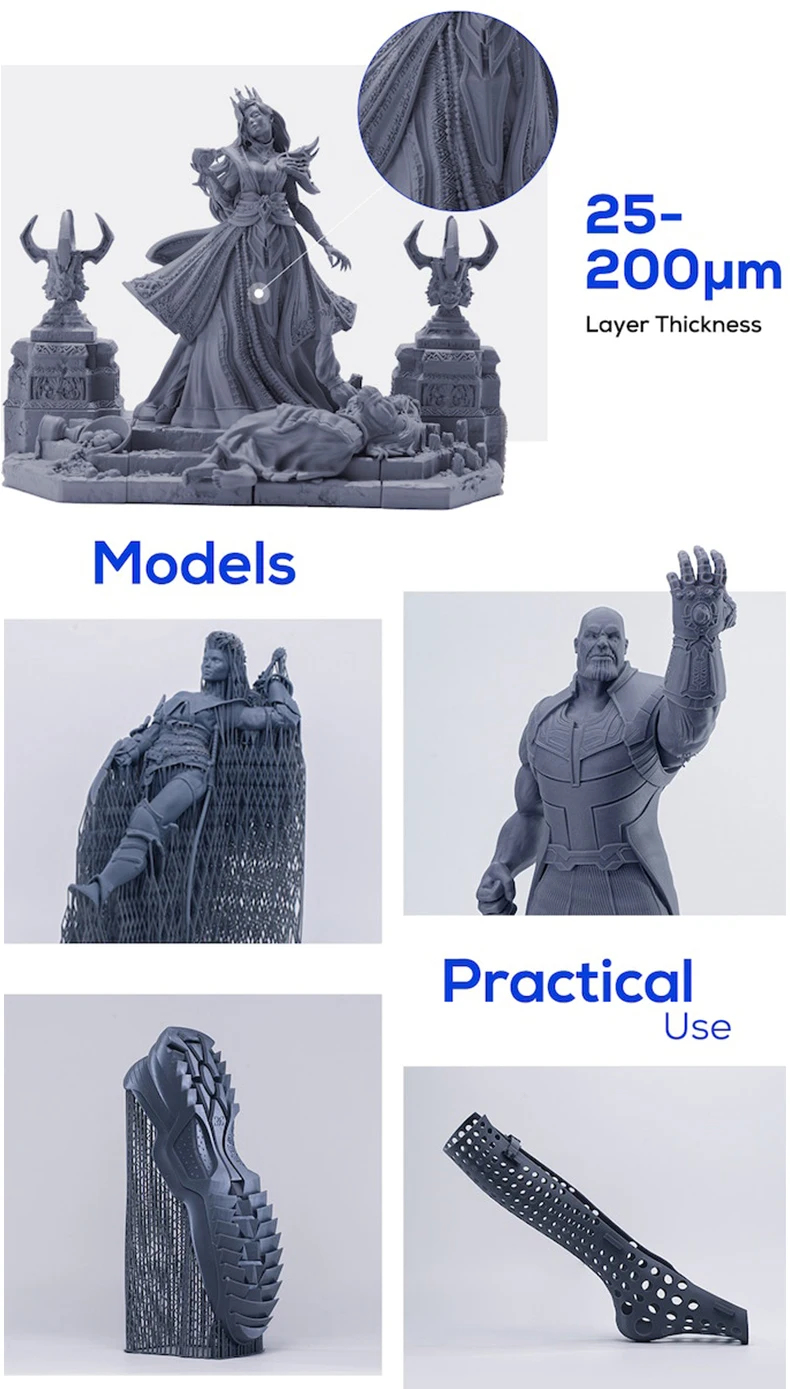

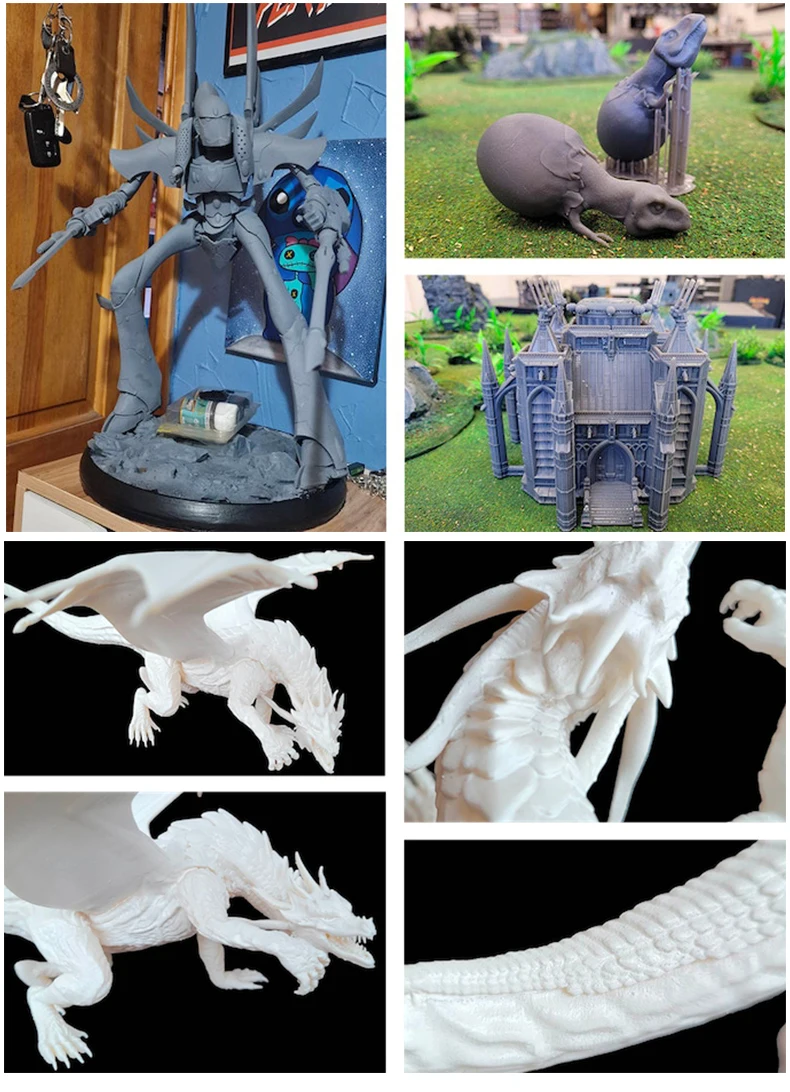

1. What is the maximum build volume of the SLA 3D Printer?

The build volume is 400 x 200 x 400 mm, allowing for large single parts or multiple smaller parts in one print.

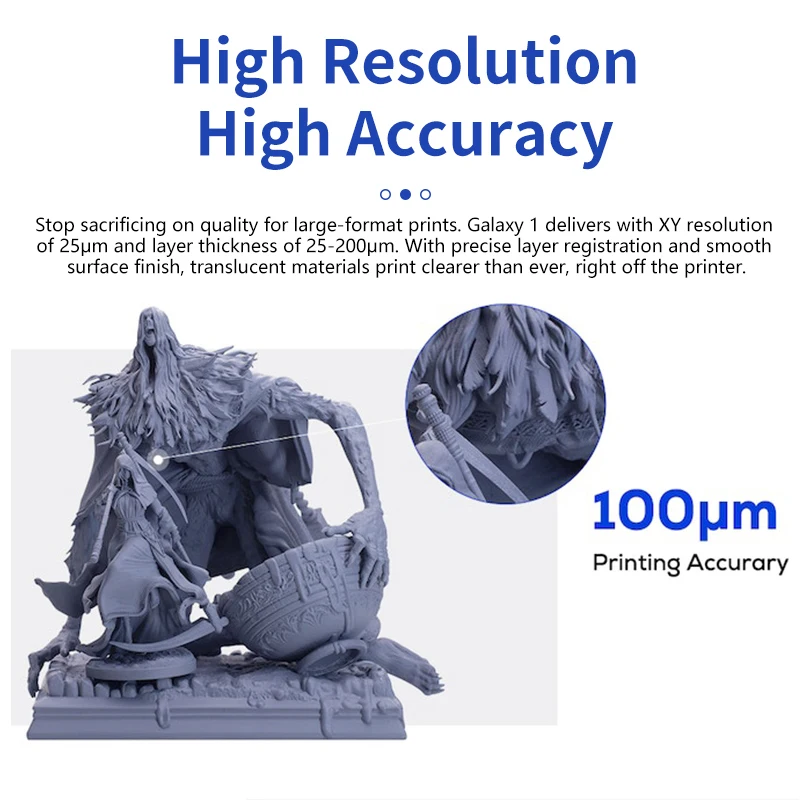

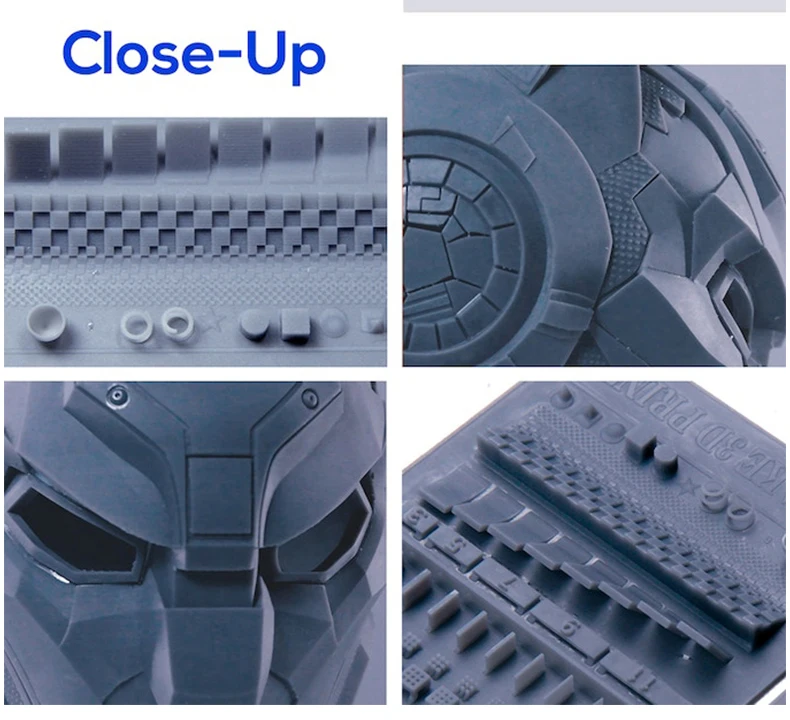

2. What resolution and layer thicknesses does the printer support?

XY resolution is 25 microns. Layer thickness options include 25µm, 50µm, 75µm and 100µm, and the product spec supports a range of 25–200µm for flexible setup.

3. What is the print speed?

Maximum print speed is up to 50 mm/h, balancing speed and print quality for prototypes and end-use parts.

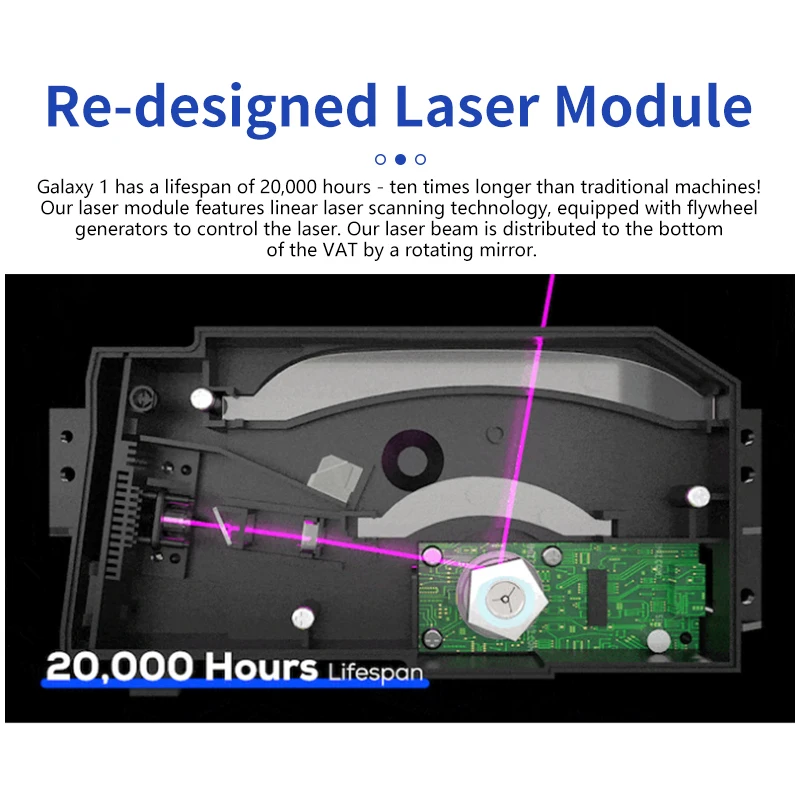

4. What light source and laser power does the machine use?

The printer uses a 405 nm light source with a laser power of 230 mW and a laser spot size of 80 µm.

5. Which materials/resins are compatible with this SLA 3D Printer?

The printer is compatible with standard 405 nm UV-curable SLA resins (engineering, flexible, castable, high-temperature, etc.). Always verify resin compatibility with your supplier and test exposure settings before production runs.

6. What software and file formats are supported?

The printer is supplied with ChiTuBox slicing software. ChiTuBox supports common 3D file formats such as STL, OBJ and 3MF for slicing and preparation.

7. How do I connect to the printer and transfer print jobs?

You can transfer print jobs using SD card or USB connection as provided on the machine.

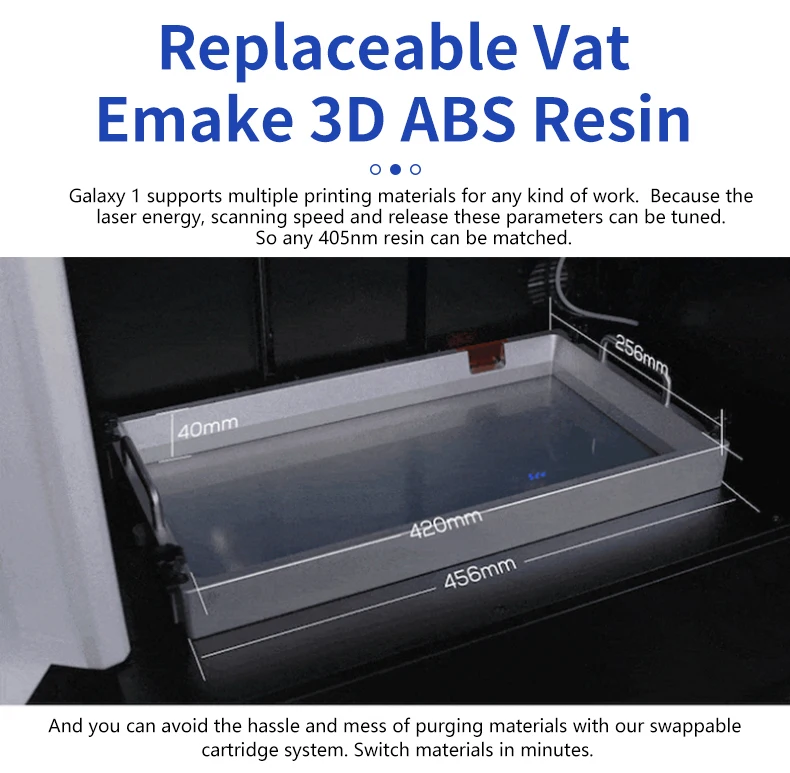

8. What is the vat size and resin capacity?

The vat size is 456 x 256 x 40 mm with a vat volume of approximately 3 liters.

9. What are the printer's physical dimensions, weight and noise level?

Overall product size is 700 x 432 x 803 mm. Net weight is 52 kg. Operating noise is below 50 dB.

10. Does the printer require temperature control or a heated chamber?

The printer has an air-heated printing room to help maintain stable printing temperatures. For best results, operate the machine in a stable-temperature environment as recommended in the user manual.

11. What routine maintenance is required?

Regular maintenance includes cleaning the vat and build plate after each print, filtering or replacing resin as needed, inspecting and cleaning optics, checking the vat film for damage, lubricating mechanical guides per the manual and keeping the workspace dust-free.

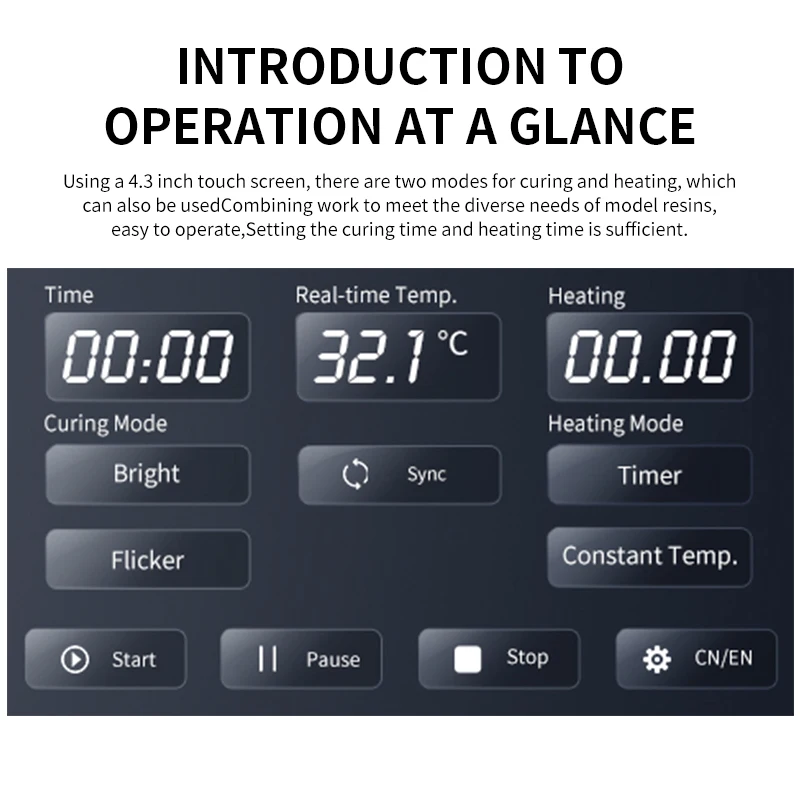

12. Is the machine easy to operate for production use?

Yes — the unit supports automatic operation, includes a 7-inch touch screen for local control, and integrates with ChiTuBox for straightforward job setup, making it suitable for industrial production with proper operator training.

13. What post-processing is required after printing?

Typical post-processing includes rinsing parts in isopropyl alcohol or recommended solvent to remove uncured resin, then final UV curing (in a curing station) to reach full mechanical properties. Always follow resin manufacturer instructions for wash and cure times.

14. What safety precautions should I follow when using the SLA printer?

Handle uncured resin with nitrile gloves and eye protection, ensure good ventilation or local exhaust, avoid direct exposure to the 405 nm light source, and follow disposal instructions for resin waste. Consult the safety data sheet (SDS) for each resin used.

15. Where can I get support, replacement parts or warranty information?

For warranty, replacement parts, calibration support or training, contact the vendor or authorized distributor from whom you purchased the printer. They can provide service plans, spare parts like vats and FEP films, and technical assistance.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading