B21, China Town Mall, Midrand

SL-25 mini CNC Lathe automatic high precision metal Slant Bed CNC lathe Machine

- Section : Machinery

- Category : Lathe

- SKU : 1600494771577

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 10 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the maximum travel span of the SL-25 mini CNC lathe?

The SL-25 mini CNC lathe has a maximum X-axis travel of 500mm and a Z-axis travel of 180mm.

2. What type of materials can the SL-25 CNC lathe work with?

The SL-25 is designed to work with various metals, ideal for turning, drilling, tapping, and contouring operations.

3. What is the spindle speed of the SL-25 lathe?

The spindle speed of the SL-25 lathe is up to 4000 rpm.

4. Does the SL-25 come with a CNC control system?

Yes, the SL-25 is equipped with the SmartBrain™ CNC control system, which provides user-friendly programming and CNC simulation.

5. What is the capacity of the hydraulic collet chuck?

The hydraulic collet chuck can hold bars up to φ24mm and single workpieces up to φ180mm.

6. Is there an automatic lubrication system in the SL-25 lathe?

Yes, the SL-25 is equipped with an automatic lubrication system to ensure smooth operation and prolong the life of the machine.

7. What features contribute to the stability of the SL-25 lathe?

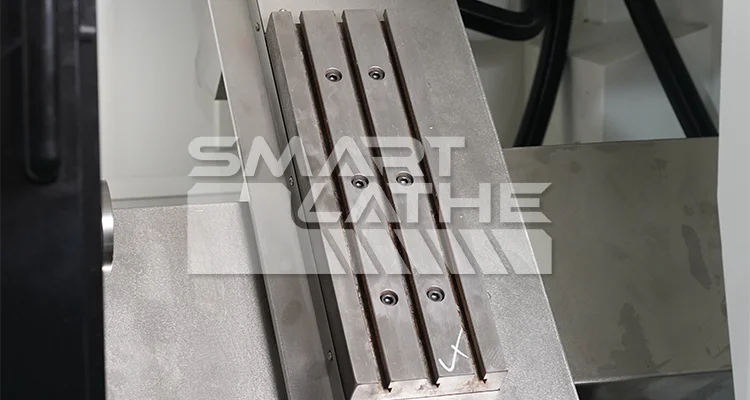

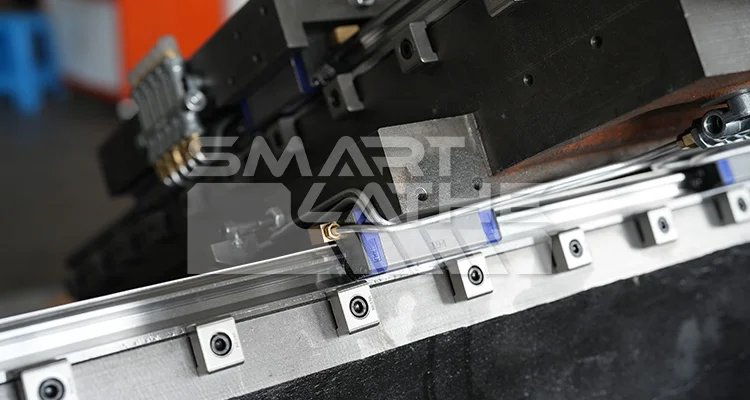

The SL-25 features a high rigidity body structure, a patented slant bed design, and hardened linear guides that enhance stability.

8. Can the SL-25 perform live tooling operations?

Yes, the SL-25 has the capability for side live tooling on the X-axis.

9. What are the dimensions of the SL-25 lathe?

The specific dimensions are not provided in the description, but the lathe features a robust design with an optimized working envelope.

10. Is there a warranty for the SL-25 mini CNC lathe?

Warranty details are typically provided by the manufacturer or seller, so it is best to check with them directly.

11. What comes included in the standard configuration of the SL-25?

The standard configuration includes a fully enclosed splash guard, spindle servo motor, telescopic guards, automatic lubrication system, coolant system, and more.

12. How does the SmartBrain CNC system enhance usability?

The SmartBrain CNC system simplifies the programming process and allows for efficient CNC simulation, making it user-friendly even for beginners.

13. What type of maintenance is required for the SL-25 lathe?

Regular maintenance includes checking the lubrication system, coolant levels, and ensuring all components are clean and functioning properly.

14. What is the power rating of the spindle motor?

The spindle motor of the SL-25 is rated at 2.2KW.

15. Can the SL-25 be used for educational purposes?

Yes, the SL-25 is suitable for educational purposes due to its user-friendly interface and versatility in various machining operations.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading