B21, China Town Mall, Midrand

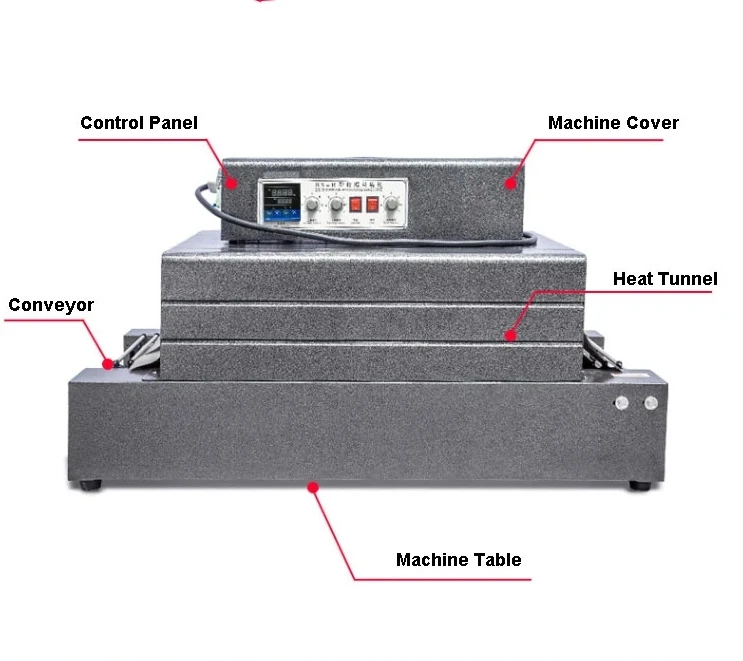

Shrink Packaging Machine (BS Series)

Model:

- Section : Machinery

- Category : Blister Packaging Machines

- SKU : 1601005085545

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 29 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What models are available in the BS Series?

The BS Series includes four models: BS-300*150, BS-400*200, BS-450*250 and BS-400*350. Each model differs by tunnel/shrink size and overall machine dimensions to suit varied product sizes and production lines.

2. What are the electrical requirements and power ratings?

The machines operate on 380V (three-phase). Power ratings vary by model from 7 kW to 10 kW (BS-300*150: 7 kW; BS-400*200: 7.5 kW; BS-450*250: 8 kW; BS-400*350: 10 kW).

3. What speed and temperature ranges does the machine offer?

Speed is adjustable from 0 to 10 m/min to match production needs. Temperature control ranges from 0 to 300°C to accommodate different shrink films and product requirements.

4. What product dimensions and conveyor loading can the BS Series handle?

Available shrinking tunnel sizes: W 350 × H 150 mm, W 400 × H 200 mm, W 450 × H 250 mm, and W 400 × H 350 mm. The conveyor loading capacity is 10 kg per item, suitable for moderate-weight products.

5. Which shrink films are compatible with this machine?

The BS Series is compatible with common heat-shrink films, including PVC, PE and POF (polyolefin). Final film choice depends on product, appearance and regulatory requirements.

6. What industries and product types is the BS Series suited for?

It’s ideal for food and beverage packaging, electronics, hardware components, pharmaceuticals, cosmetics and many other industries that require consistent shrink wrapping.

7. How do I estimate throughput (units per hour)?

Throughput depends on product length and line speed. Use: units/hour = (speed in m/min × 60) ÷ product length in meters. Example: at 5 m/min with 0.25 m long products: (5 × 60) ÷ 0.25 = 1,200 units/hour.

8. How easy is the machine to operate?

The BS Series features user-friendly controls for temperature and speed adjustments, allowing quick setup and minimal operator training. Clear controls reduce operator errors and speed up changeovers.

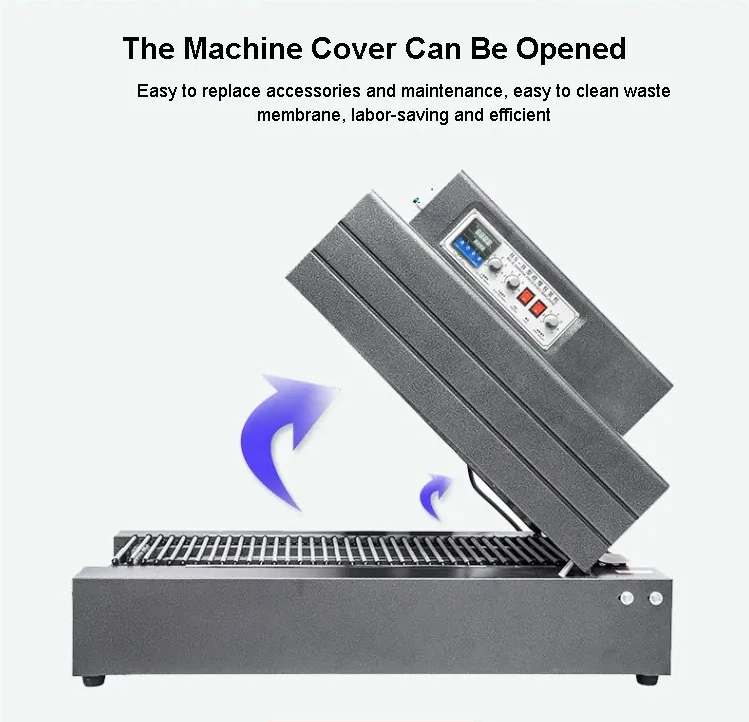

9. What routine maintenance is required?

Regular maintenance includes cleaning the conveyor and tunnel, checking and tightening belts/rollers, inspecting and replacing worn heating elements, verifying sensors and electrical connections, and keeping ventilation paths clear.

10. What safety features are included?

Standard safety measures include emergency stop(s), thermal protection/over-temperature sensors and insulated tunnel panels. We recommend proper guarding, operator training and compliance with local safety regulations.

11. What are the machine dimensions for each model?

Approximate machine dimensions are: BS-300*150: 111 × 53 × 69 cm; BS-400*200: 120 × 62 × 68 cm; BS-450*250: 120 × 66 × 69 cm; BS-400*350: 120 × 70 × 82 cm.

12. Can the machine be customized or integrated into an existing line?

Yes. The BS Series offers different model sizes and can usually be customized (film handling, infeed/outfeed conveyors, automation options). Contact sales with your specifications for integration or OEM requirements.

13. Are spare parts and service available?

Common spare parts (heating elements, conveyor belts, sensors, thermostats) and technical support are available. Contact your supplier for part numbers, lead times and service contracts.

14. What installation requirements should I prepare for?

Provide a dedicated 380V three-phase supply with proper grounding, sufficient floor space per the chosen model dimensions, good ventilation/exhaust for the tunnel area, and a level installation surface. Professional electrical hookup is recommended.

15. What warranty and after-sales support are offered?

Warranty terms and after-sales support packages vary by supplier and region. Please contact the vendor or sales representative for specific warranty duration, coverage details and available service plans.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading