B21, China Town Mall, Midrand

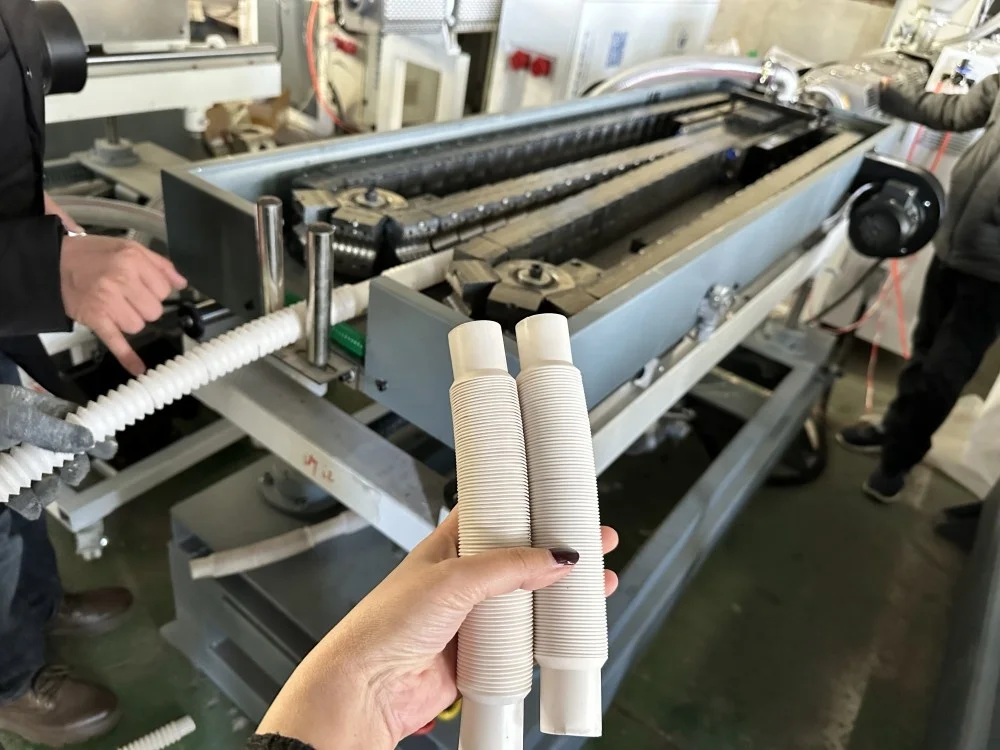

Shrink Corrugated Shisha Hookah Pipe Production Machine No reviews yet

- Section : Machinery

- Category : Manufacturing Machinery

- SKU : 1601118150357

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 01 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What materials can the Shrink Corrugated Shisha Hookah Pipe Production Machine handle?

The machine can handle PVC powder, granules, and PP/PE/EVA materials.

2. What is the production speed of this machine?

The production speed of the machine is 20-30 meters per minute.

3. Is the machine energy efficient?

Yes, the machine is equipped with a heater ring that saves 30% of electricity, enhancing energy efficiency.

4. What types of pipes can this machine produce?

This machine can produce a range of pipes, including those for air conditioning, medical breathing, washing machine drainage, electrical wire conduits, and shisha hookah hoses.

5. How does the cooling system work?

The machine uses a water-circulating cooling system to ensure high-speed molding and smooth pipe formation.

6. What are the key features of the SJ65/30 Single Screw Extruder?

The SJ65/30 Single Screw Extruder offers a higher fusion rate, stable continuous production, and can be operated with either PLC or manual control systems.

7. How easy is it to change the size of the pipes during production?

The machine features a core bar and mouth mold design that allows for easy size changeover, reducing downtime by up to 1.5 hours.

8. What kind of after-sales support does Fullwin provide?

Fullwin offers comprehensive after-sales support, including onsite installation, commissioning, worker training, maintenance services, free spare parts, and video/online technical support.

9. Can the machine be customized for specific needs?

Yes, Fullwin provides custom machine designs to suit your specific production needs.

10. What is the purpose of the double station winding machine?

The double station winding machine automatically balances the speed between pipe production and rewinding, preventing tightness or disconnection of the pipe during the process.

11. Is training provided for operating the machine?

Yes, Fullwin provides worker training at your site to ensure proper operation of the machine.

12. How long does it take to clean the machine?

The new design allows for reduced cleaning time by over 1.5 hours due to simultaneous changing of the core bar and mouth mold.

13. What are the benefits of using the Shrink Corrugated Shisha Hookah Pipe Production Machine?

The machine offers high efficiency and speed, energy-saving features, ease of maintenance, and comprehensive after-sales support.

14. Can I see a demonstration of the machine before purchasing?

Yes, Fullwin can provide a demonstration or testing of the machine before delivery to ensure everything runs smoothly.

15. What applications are suitable for the pipes produced by this machine?

The pipes produced by this machine are suitable for air conditioning systems, shisha hookah hoses, medical breathing pipes, washing machine drainage, and electrical wire conduits.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading