B21, China Town Mall, Midrand

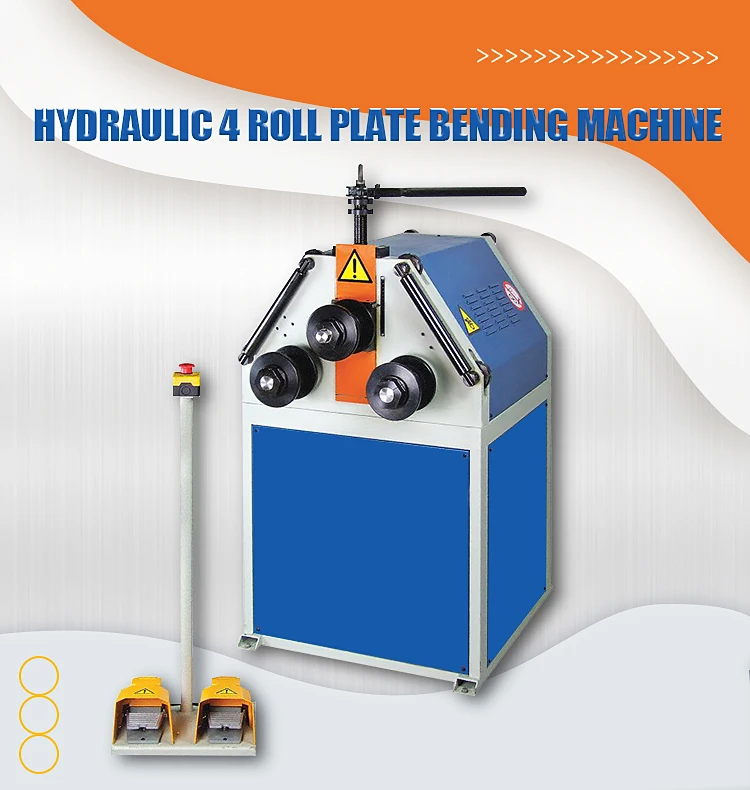

Sheet Round Bending Machine

- Section : Machinery

- Category : Metal & Metallurgy Machinery

- SKU : 1600141563763

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 29 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What materials can the Sheet Round Bending Machine process?

It can process a wide range of metals including alloy, aluminum, stainless steel and carbon steel. It is specifically designed for round and section bars as well as pipe tubes and profile sheets.

2. Is this machine fully automatic or semi-automatic?

This is a semi-automatic machine. It automates the bending process while still requiring an operator for tasks such as loading/unloading, positioning and some parameter inputs.

3. What are the key features of the machine?

Key features include high-accuracy bending, dual horizontal and vertical operation modes, robust steel-welded construction (200 kg machine weight), full-hydraulic four-roller design, Siemens Beide motors and Siemens electrical components, and standard combination molds for multiple shapes.

4. What bending profiles and shapes can it produce?

The machine is designed to bend round bars, section bars, pipe tubes and profile sheets into arcs, cones and other simplified curved parts. It can also perform steel plate leveling in cold conditions using the four-roller configuration.

5. What is the maximum thickness and diameter it can bend?

Maximum thickness and diameter depend on the specific model, tooling and material. Please provide the material type, dimensions and desired bend radius so we can confirm capacity or recommend a suitable model.

6. What power and electrical requirements does the machine have?

The machine uses Siemens Beide motors and Siemens electrical components. Exact power ratings and supply requirements vary by configuration; contact sales or request the technical datasheet for precise electrical specifications for your model.

7. Are tooling and molds included with the machine?

Standard combination molds are typically included to handle a variety of common shapes. Specialized tooling, custom dies or additional mold sets may be offered as optional accessories or quoted separately.

8. Can the machine be customized or ordered as OEM?

Yes. OEM and custom solutions are accepted. Customization options commonly include capacity changes, special tooling, control upgrades, paint color and other adaptations to meet specific production requirements.

9. What installation and site requirements are needed?

Installation typically requires a level, stable foundation, adequate floor load capacity, correct electrical supply, and hydraulic oil filling/bleed procedures. Many suppliers offer installation and commissioning services—confirm with your vendor for site-specific requirements.

10. What maintenance is required to keep the machine running reliably?

Regular maintenance includes checking and changing hydraulic oil, inspecting and lubricating moving parts and rollers, verifying electrical connections, monitoring seals and hoses, and replacing worn tooling. Follow the manufacturer’s maintenance schedule in the user manual.

11. What safety features does the machine have?

The machine includes a reliable push-button control panel and hydraulic controls. Standard safety best practices include emergency stop capability, guarding around rollers, hydraulic overload protection, and operator PPE and training. Specific safety features may vary by configuration.

12. How accurate are the bends produced by this machine?

The machine is engineered for high accuracy, but achievable tolerances depend on material, thickness, tooling and operator setup. Provide your required tolerances and material details to get an expected accuracy specification for your application.

13. Is training and technical support provided?

Yes. Suppliers commonly provide operator training, start-up assistance and technical support. Options may include remote support, onsite commissioning, and training sessions—confirm availability and scope with your vendor.

14. Are spare parts and after-sales service available?

Spare parts and after-sales service are available. The machine uses widely known Siemens components, and suppliers typically stock common wear parts and provide service agreements for longer-term support.

15. What are typical lead times and warranty terms?

Lead times and warranty terms vary by model, configuration and current production schedule. Contact the sales team for up-to-date lead time estimates and specific warranty coverage (duration and terms) for the configuration you plan to purchase.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading