B21, China Town Mall, Midrand

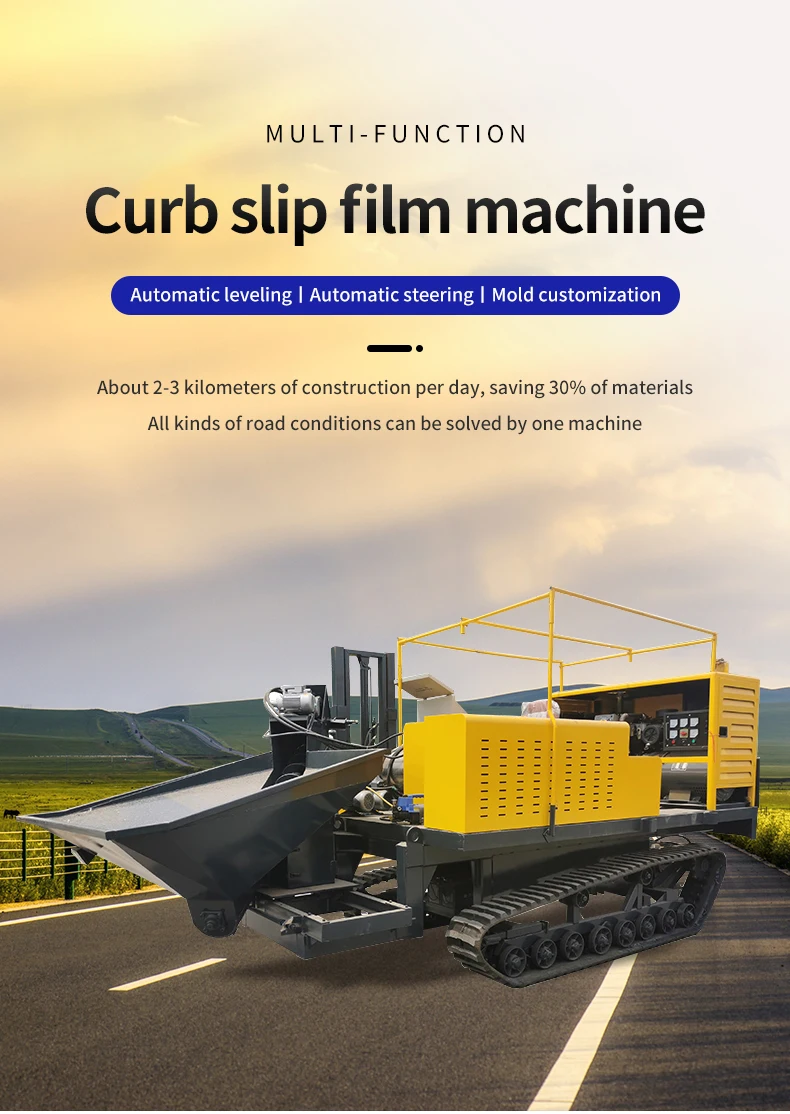

Road Curb Slip Film Making Machine (5m) Road Construction Machinery

- Section : Machinery

- Category : Construction Machinery

- SKU : 1600903088749

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 06 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the model and primary use of this machine?

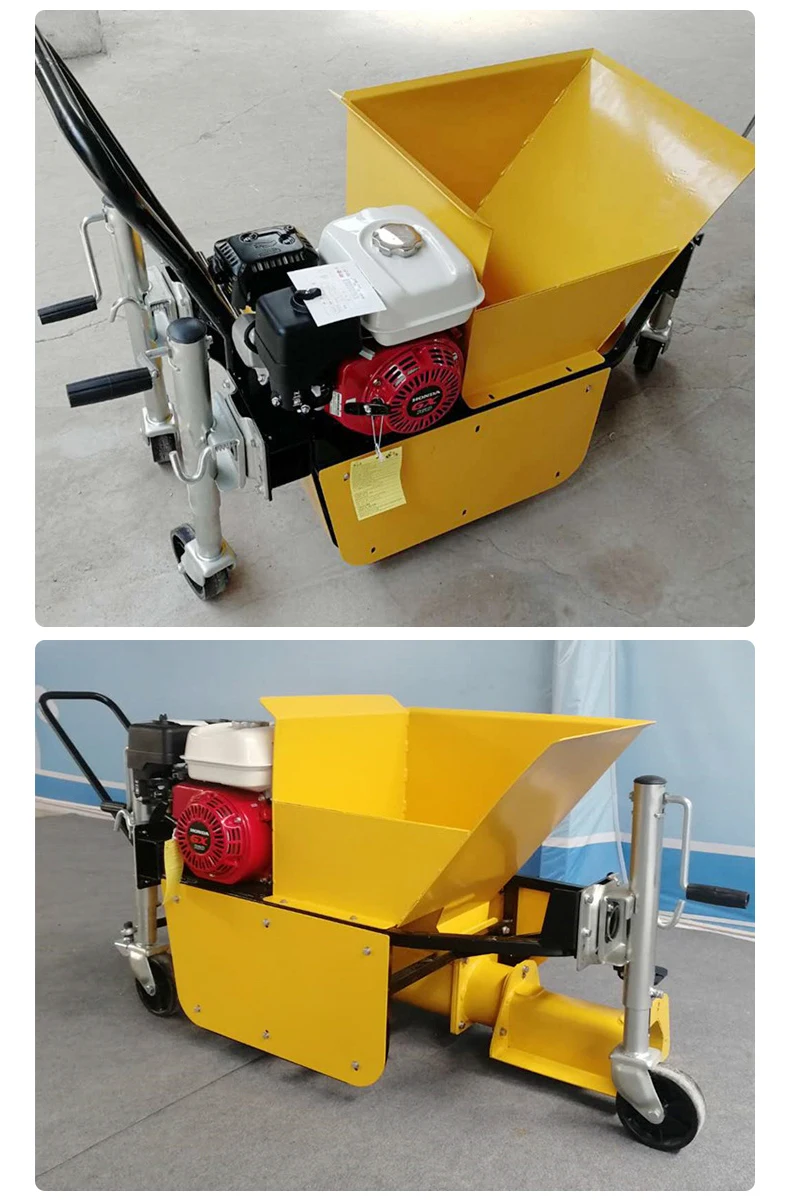

Model ID-ST11 is a self-propelled, walk-behind slip-form curb (curb stone) molding machine used to extrude and form road/landscape curbs for parks, community gardens and small roadworks.

2. What power options are available?

Two power options are available: gasoline (GX160 engine, 5.5 HP) and diesel versions. Please confirm preferred power type when ordering.

3. What are the machine's key dimensions, weight and package size?

Machine dimension: 1670 × 700 × 1100 mm. Package size: 1560 × 810 × 970 mm. Net weight: 160 kg. Oil capacity: 3.6 L.

4. What curb sizes can this machine produce?

This machine can produce small curbs up to approximately 200 mm in height and up to 180 mm in width. Exact size and profile depend on the selected mold.

5. What is the working speed / production rate?

Typical working speed is 1–2 m/min, depending on mix consistency, mold shape and operator skill.

6. Which molding/extrusion method does ID-ST11 use?

The ID-ST11 uses a spiral-blade extrusion (spiral feeding hopper) that pushes concrete/asphalt-sand into the mold while the reaction force helps move the machine. Some other curb machines use hammer extrusion; please confirm if you require that system.

7. What construction materials can be used with this machine?

Suitable for cement concrete mixes and asphalt-sand (tar-sand) mixes intended for extruded curbs. Note: curbs should not be laid directly on asphalt pavement; they must be placed on a water-stable base layer (except designated asphalt-sand catchment zones).

8. How are molds selected and ordered?

Molds are customizable. Choose the desired mold number from the available list and inform the seller; they will check mold availability and cost. Custom profiles can also be designed to customer requirements.

9. What controls and sensors are included?

Includes a walking-direction indicator, imported high-precision hydraulic valves, an automatic walking precision sensor (accuracy <1 mm), an electronic level sensor for left-right balance, and protected control buttons.

10. What regular maintenance is required?

Daily: clean hopper, mold and spiral blade; check hydraulic and engine oil levels; inspect sensors and control buttons. Weekly/monthly: check belt/chain tension, fasteners, and blade wear; service engine per manufacturer schedule. Replace worn parts promptly.

11. What accessories and spare parts are commonly available?

Common accessories include various mold profiles, spare spiral blades, seeding/extrusion screws, sensors, control buttons, and standard engine spare parts. Ask the supplier for a recommended spare-parts kit.

12. Is operator training provided or required?

Operators should be trained on safe operation, mix preparation, mold installation and level/sensor use. Many suppliers provide an operation manual and can arrange remote or on-site training—confirm with the seller.

13. Are there safety or site-preparation requirements?

Yes. Use appropriate PPE, ensure a water-stable foundation (not fresh asphalt), maintain clear travel path, check level and direction indicators, and avoid operating on slopes or unstable ground. Follow engine and hydraulic safety practices.

14. How is the machine packaged and shipped, and what should I consider for transport?

The machine ships in the package dimensions above (1560 × 810 × 970 mm) and weighs about 160 kg. It is palletizable; consider forklift access and local import/shipping regulations. Confirm lead time and shipping method with the supplier.

15. What are warranty and after-sales support options?

Warranty terms and after-sales support vary by supplier and region. Typical offerings include parts support, technical assistance and optional extended warranties—confirm exact terms, response times and spare-part availability with the seller before purchase.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading